Non-woven fabric foaming liner material for automobile seat cushion and preparation process of non-woven fabric foaming liner material

A technology for car seat cushions and cushion materials, applied in the field of non-woven fabric foam cushion materials and its preparation process, can solve the problems of inconvenient recycling of fibers and high cost, and achieve prevention of abnormal sound, high recycling, and prevention of liquid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

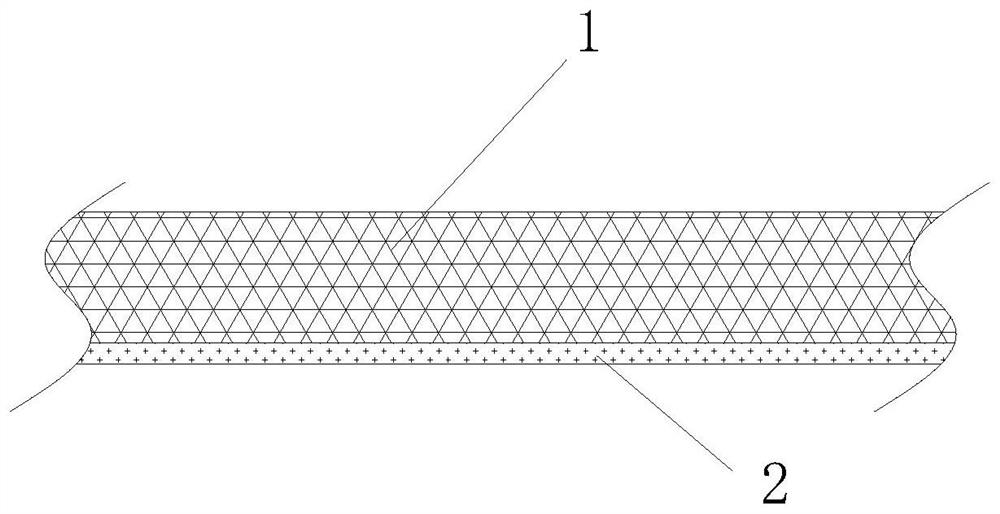

[0022] A preparation process of a non-woven foamed cushion material for automobile seat cushions, the specific steps are as follows: 1) mixing hydrophilic polyester fiber and back-spun polyester, stretching, carding, laying, and drafting to form a cotton net , using a blender to mix materials, stretching with an air-pressure cotton box, and using a web-laying machine to card, lay, and draft to make a cotton web; lay the cotton web made of hydrophilic polyester fibers on the cotton web of back-spun polyester , sent to the spunlace reinforcement area for simultaneous spunlace reinforcement to make a double-layer non-woven fabric; 4) winding double-layer non-woven fabric.

[0023] The hydrophilic group in the hydrophilic polyester fiber is a hydroxyl group. The back-spun polyester is polyethylene terephthalate resin. The spunlace reinforcement treatment adopts drum spunlace reinforcement, the number of spunlace heads is 10, the aperture of the spunlace plate is 0.1mm, and the de...

Embodiment 2

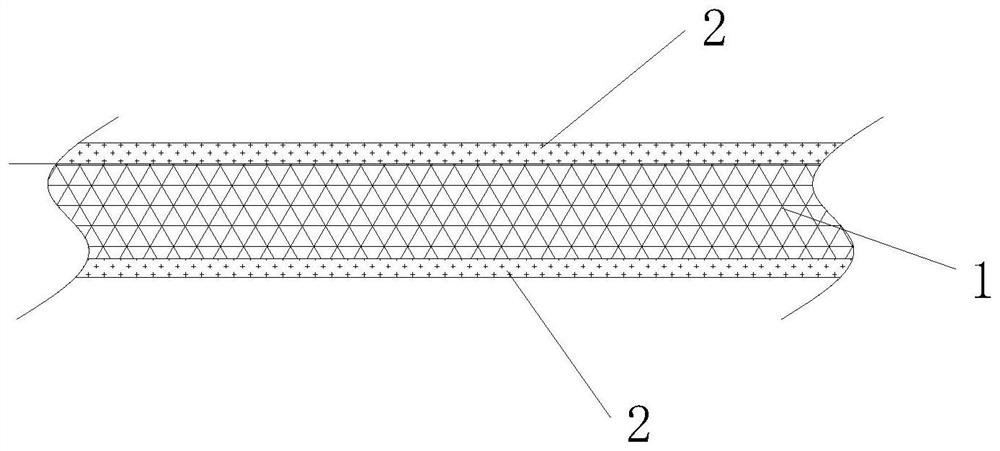

[0025] A preparation process of a non-woven foamed cushion material for automobile seat cushions, the specific steps are as follows: 1) mixing hydrophilic polyester fiber and back-spun polyester, stretching, carding, laying, and drafting to form a cotton net , using a blender to mix materials, stretching with an air-pressure cotton box, and using a web-laying machine to card, lay, and draft to make a cotton web; lay the cotton web made of hydrophilic polyester fibers on the double-layer back-spun polyester The middle of the cotton net is sent to the spunlace reinforcement area for simultaneous spunlace reinforcement to form a three-layer non-woven fabric; 4) winding the three-layer non-woven fabric.

[0026] The hydrophilic groups in the hydrophilic polyester fibers are carboxyl groups. The back-spun polyester is polyethylene terephthalate resin. The spunlace reinforcement treatment adopts drum spunlace reinforcement, the number of spunlace heads is 15, the aperture of the sp...

Embodiment 3

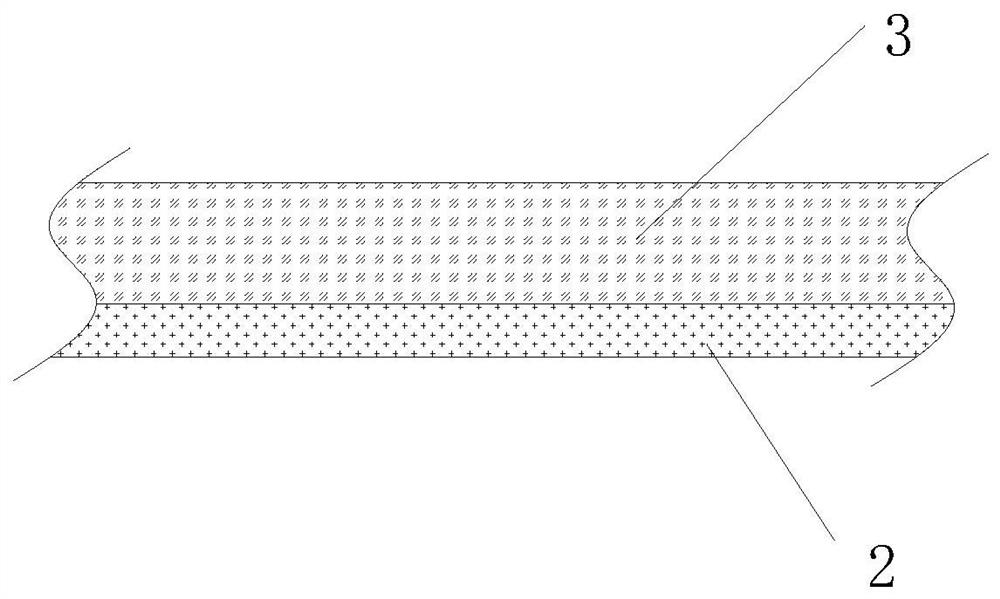

[0028] A preparation process of a non-woven foamed cushion material for automobile seat cushions. The specific steps are as follows: 1) The mixture of hydrophilic polyester fiber and low-melting point polyester fiber and the back-spun polyester are respectively mixed, stretched, carded, and spread. Cotton net is made by netting and drafting, which is mixed by a mixer, stretched by an air pressure cotton box, and carded, laid and drafted by a web lapper to form a cotton net; the cotton net made of mixed polyester fibers is laid On the back-spun polyester cotton net, send it to the spunlace reinforcement area for simultaneous spunlace reinforcement to make a double-layer non-woven fabric; 4), heat the double-layer non-woven fabric made; 5) Wind the double-layer non-woven fabric non-woven fabric.

[0029] The weight ratio of the hydrophilic polyester fiber to the low melting point polyester fiber is 9 / 1.

[0030] The hydrophilic groups in the hydrophilic polyester fibers are car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com