Copper scale sweeping device

A technology of copper scraps and pressure device, which is applied in metal processing, cleaning methods and utensils, and cleaning methods using tools, etc., can solve the problems of large copper tumor of electrolytic copper foil, malfunction of electrical products, etc., and achieve good practical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

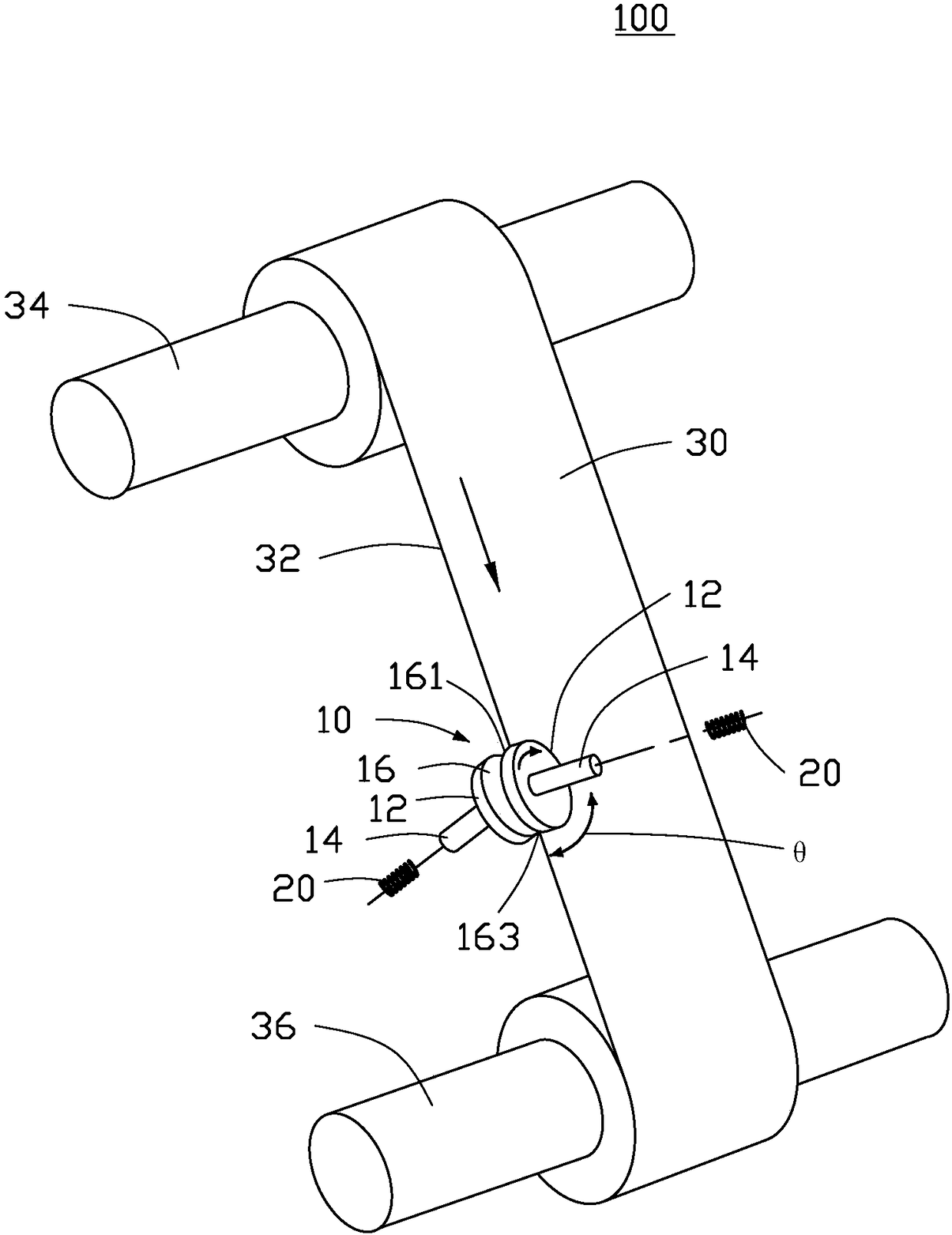

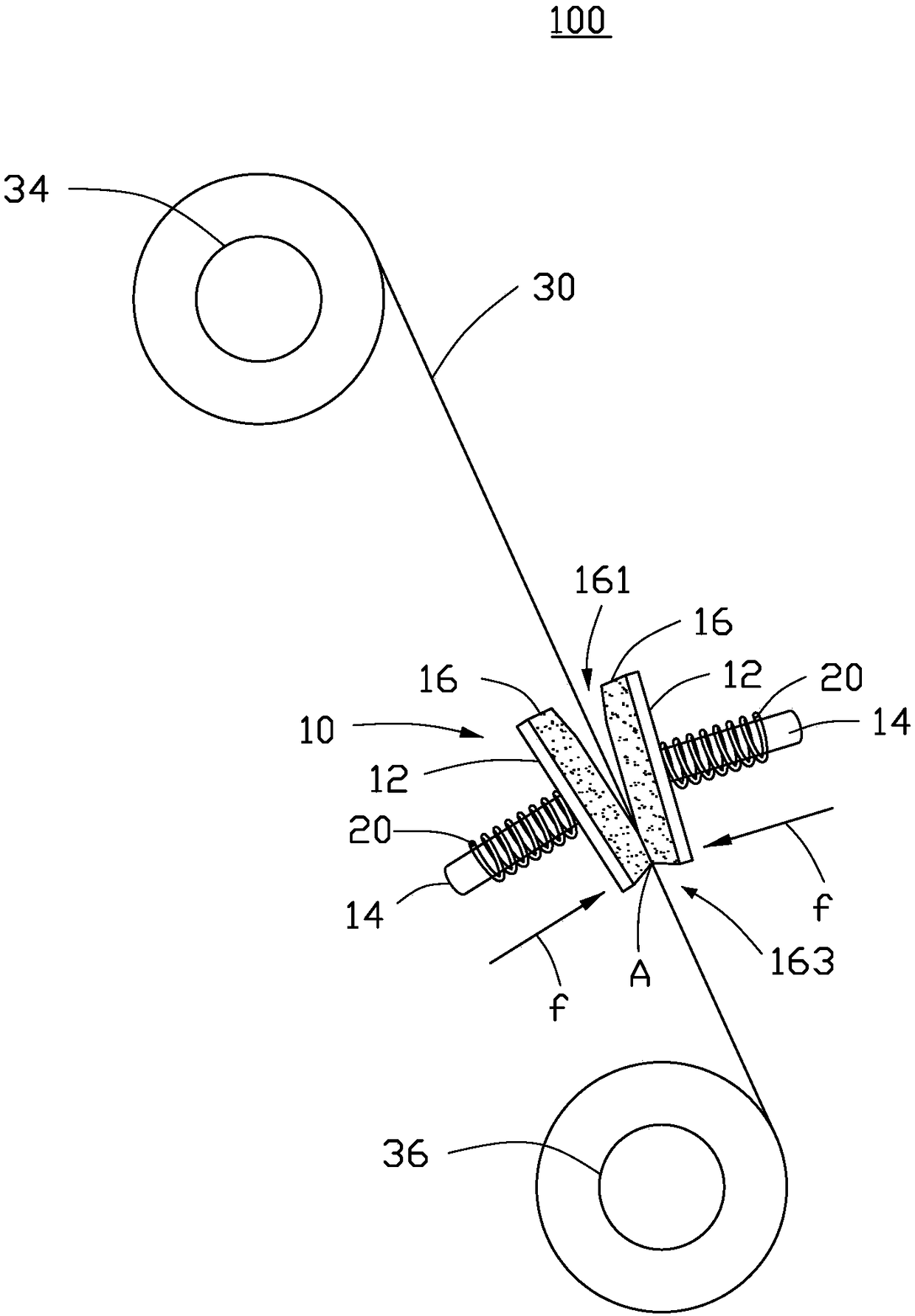

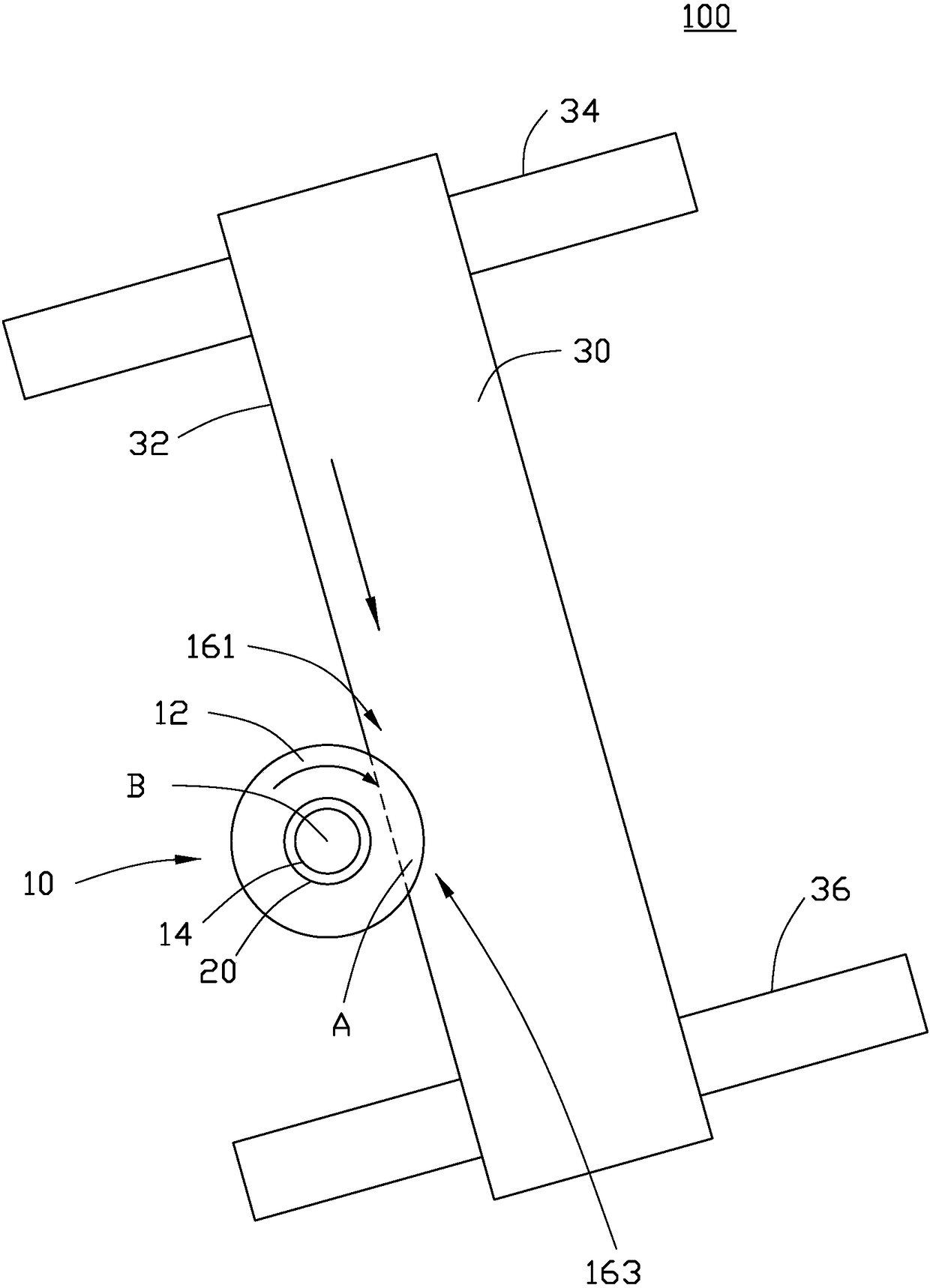

[0028] see figure 1 It is a three-dimensional schematic view of a specific embodiment of the copper scrap removal device of the present invention. The copper shavings removal device 100 includes at least one roller set 10 and at least one pressure device 20, the roller set 10 has two free wheels 12 oppositely arranged, and the two free wheels 12 are respectively supported by a wheel shaft 14, and the two free wheels 12 Each of the freewheels 12 has a plane of symmetry 16 respectively. The extension lines of the two axles 14 of the two free wheels 12 intersect, and the two axles 14 are respectively arranged opposite to each other at an inclination angle θ, and the inclination angle θ makes the two of the two opposite free wheels 12 The symmetrical plane 16 forms a feeding end 161 and a sweeping end 163 . The inclination angle θ is an angle between the wheel shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com