Fuse-plug dam section test method using overflow water tank synchronous stacking narrow groove and pipe

A test method and flow tank technology, applied in hydraulic models and other directions, can solve the problems of dissimilar materials and dissimilarity of test water supply flow, and achieve the effects of low cost, small water consumption and simple test method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

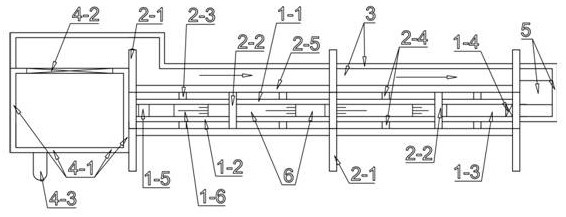

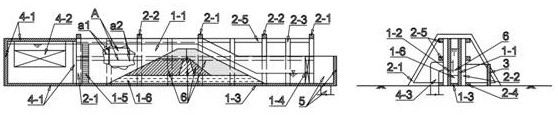

[0023] Example 1: A test example of a self-collapsing dam with a parent clay core wall of sub-geotechnical anti-seepage panels. There are many new self-collapsing dams to be tested in a certain watershed. If the new self-collapsing dams are low and the water supply meets the requirements of the overall test, the prototype test of the overall section can be carried out; It is necessary to carry out the top local prototype narrow groove test to find out the water head required for the safe cutting rate at the top of the mother clay core wall and the burst time of the sub-self-collapsible dam; The local prototype of the clay anti-seepage body has been compressed and narrowed in layers to obtain the self-rupture dam burst process. details as follows:

[0024] The self-collapsing dam section test method of the overflow tank synchronously stacked with narrow groove pipes, which utilizes the overflow water tank synchronously stacked open narrow grooves and the overflow water tank is...

Embodiment 2

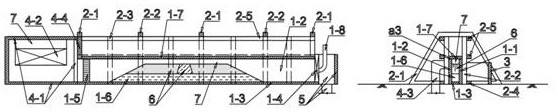

[0028] Example 2: A cross-sectional test example of a self-collapsing embankment with a flooded clay core wall. If the self-collapsing dam is low and the water supply for the overall test meets the requirements, the overall cross-section prototype test can be carried out; if the self-collapsing dam is high, the downstream flood control does not require the process of self-collapsing dam collapse, and only the local prototype narrow groove test on the top is needed to find out the clay core. The water head and burst time required for the safe cutting rate at the top of the wall; if the self-collapsing dam is high, the prototype cross-section test cannot meet the water supply requirements, and the downstream flood control requires the self-collapsing dam burst process, and the local prototype of the clay anti-seepage body has compression narrowing tube, obtained from the dam burst process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com