Sliding door arrangement

A sliding door and facility technology, applied in the direction of windows/doors, door/window accessories, power control mechanisms, etc., can solve problems such as lowering of lifting magnets, and achieve the effect of reducing electrical wiring, reducing structural space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

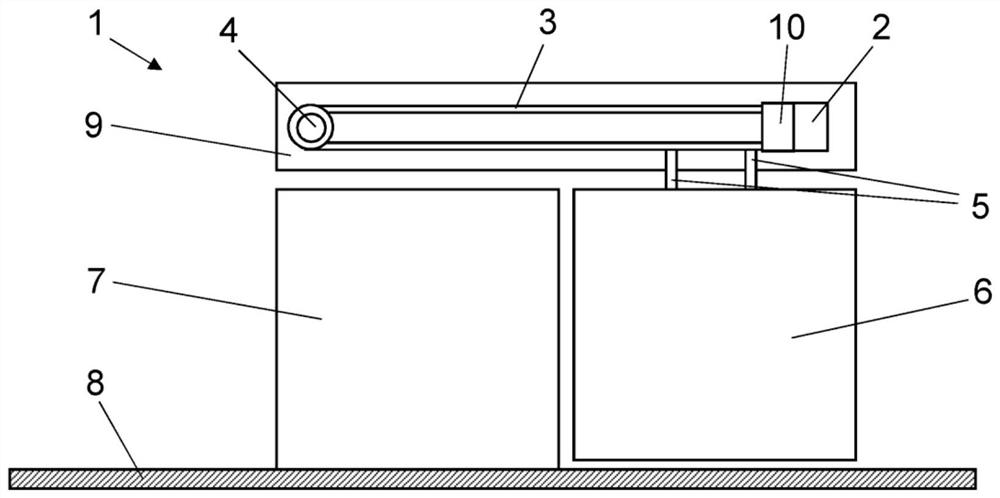

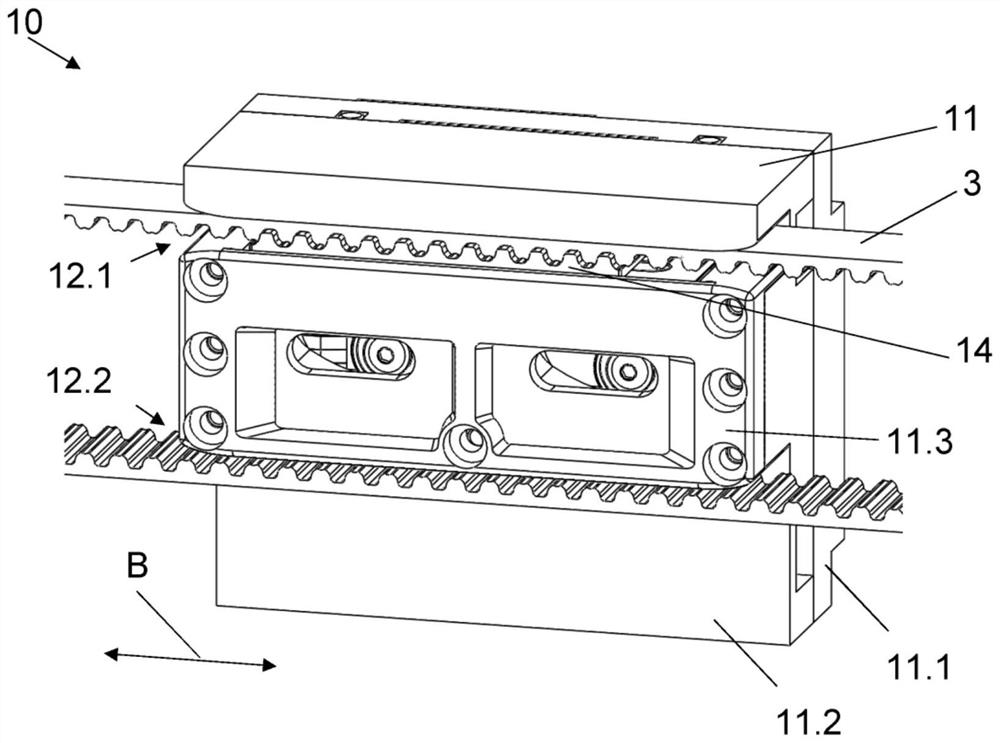

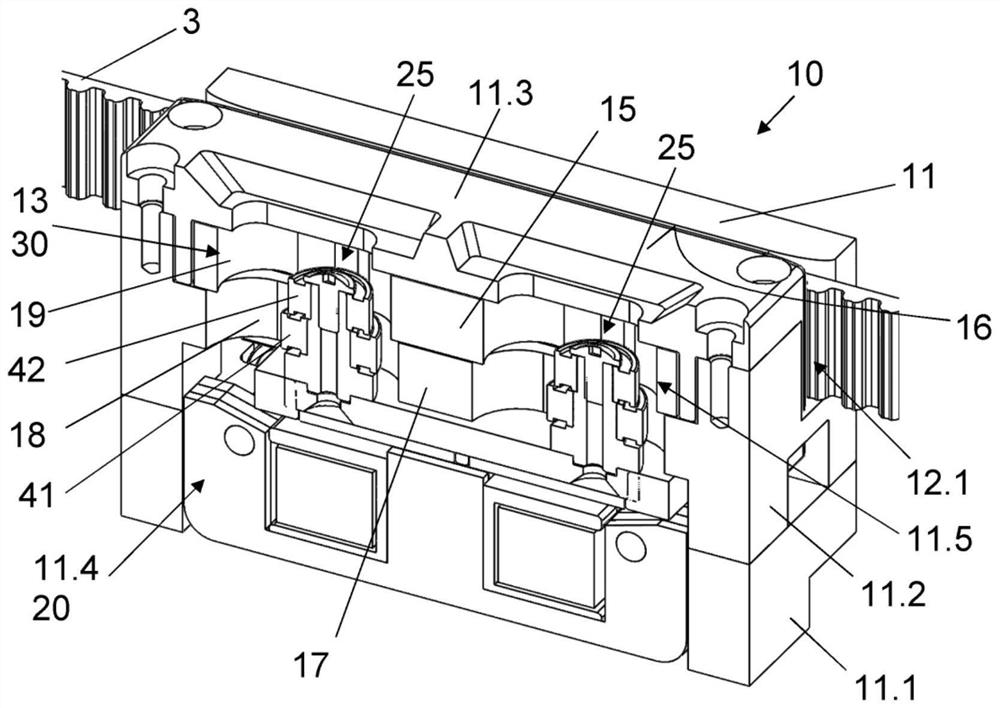

[0055] in figure 1 A schematic diagram of the sliding door facility 1 is shown in. The sliding door installation 1 includes a sliding door element 6 and a door driver 9, via which the sliding door element 6 can be moved in a motor-driven manner, for example in figure 1 Movement between the closed position shown in and the open position in which the sliding door element 6 is arranged in the door opening, and in the open position the sliding door element 6 is at least partially arranged in the wall element 7 Rear and release the door opening here. According to one embodiment, the door driver 9 is arranged above the sliding door element 6 of the sliding door installation 1. However, it is also conceivable that the door drive 9 is alternatively arranged under the sliding door element 6, for example between the sliding door element 6 and the floor 8 or in the floor 8 under the sliding door element 6.

[0056] The door driver 9 of the sliding door installation 1 includes an electric m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com