Pipe transportation vehicle

A technology for transporting tube vehicles and wheels, which is applied to vehicles for carrying long goods, lifting devices, lifting frames, etc., and can solve the problems of low return on investment and production efficiency, difficulty in designing and using the tube transporting vehicles, and the difficulty of moving the tube transporting vehicles and lifting space limitations, etc., to avoid unbalanced problems, meet the use requirements, and reduce electrical circuits and control modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

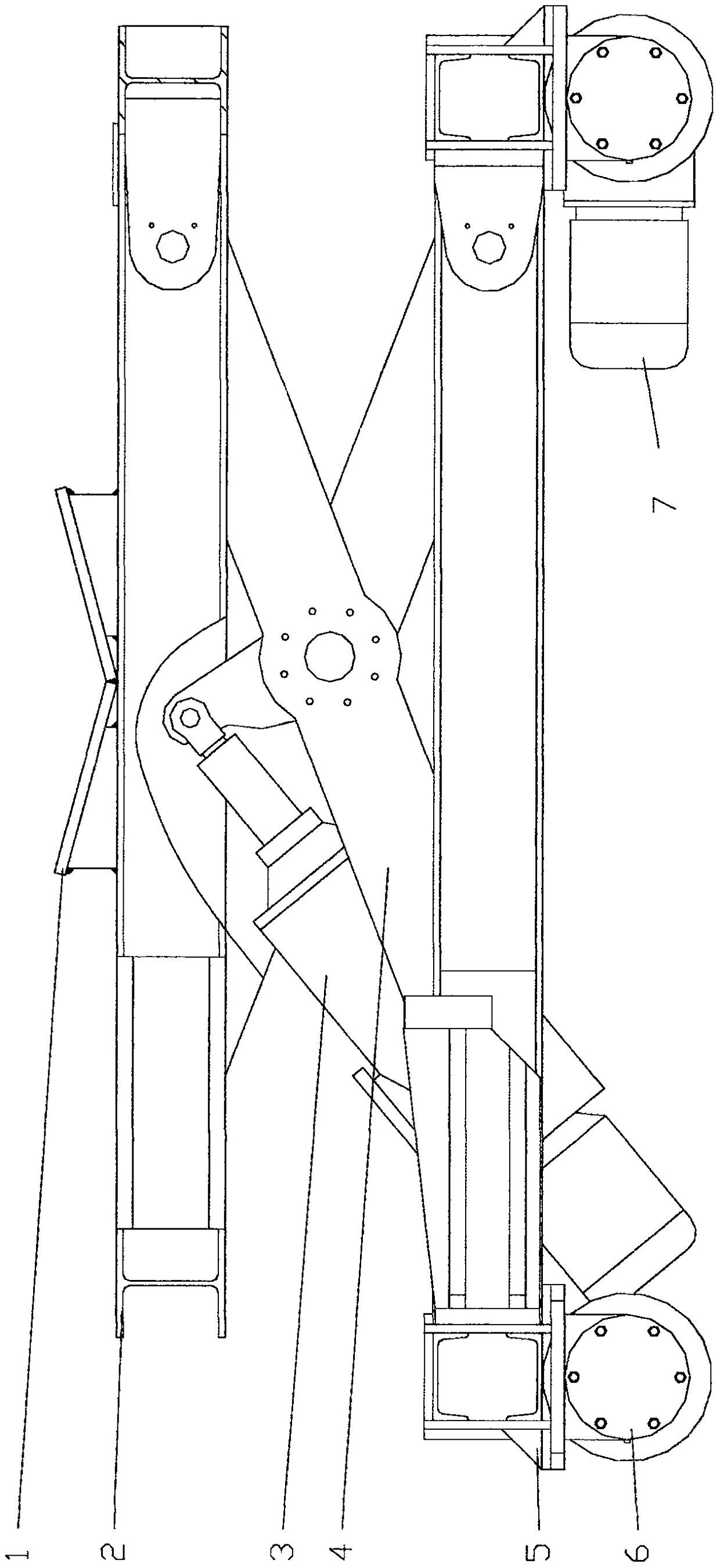

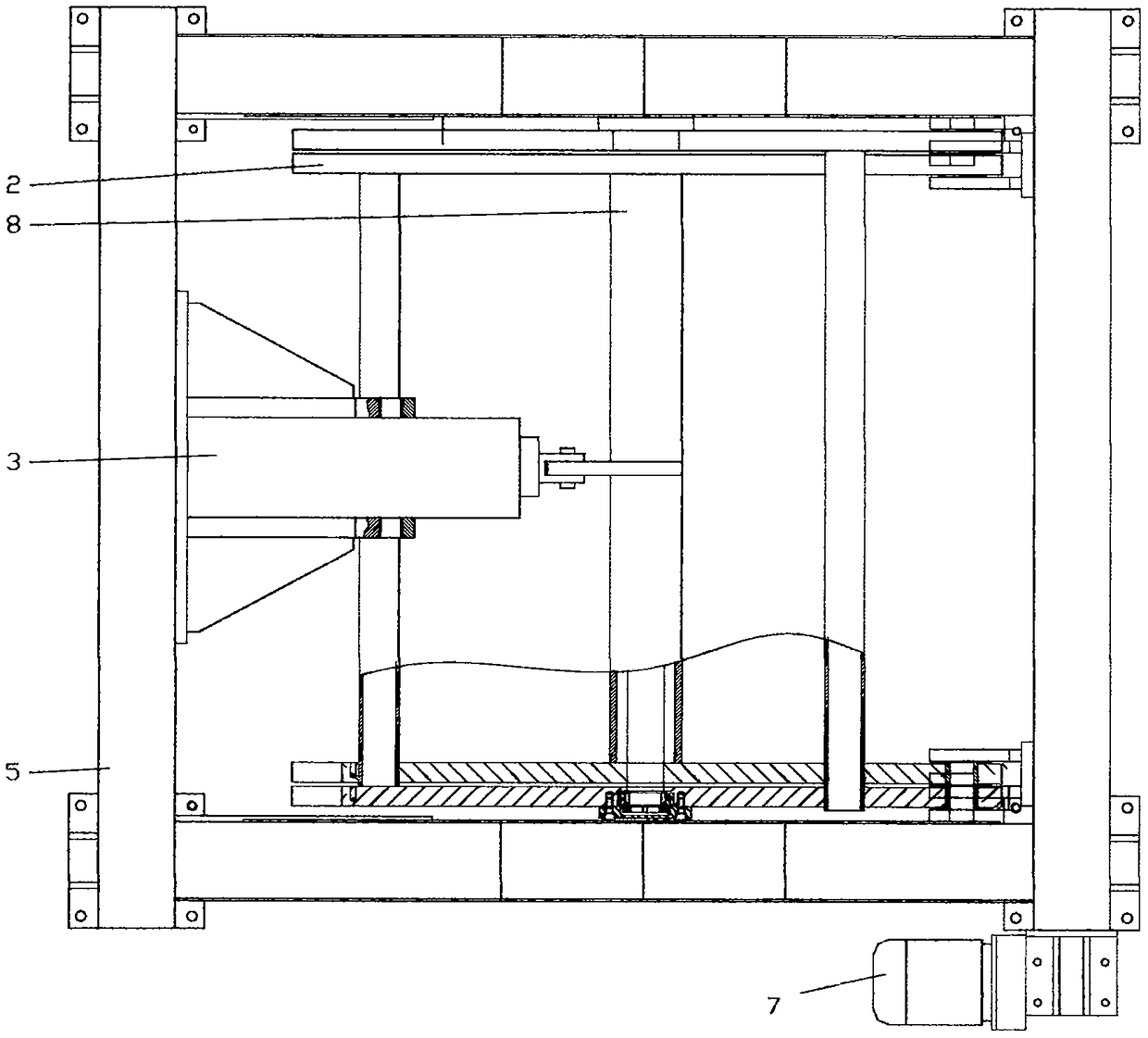

[0009] Such as figure 1 , 2 As shown, the lower end of the lower frame 5 is fixed to the wheel 6, the wheel 6 is driven by the travel motor 7, the lower frame 5 is hinged with the upper frame 2 through the scissors brace 4, and the upper end of the upper frame 2 is fixed to the cast pipe support 1, so The scissor support 4 described above is driven by the electro-hydraulic push rod 3 hinged on the lower frame 5 .

[0010] The electro-hydraulic push rod 3 is hinged to the inner side wall of the lower frame 5, which can reduce the height of the vehicle.

[0011] There is only one electro-hydraulic push rod 3, which greatly reduces the cost of the hydraulic system.

[0012] The motor 7 is fixed on the outside of the lower frame 5, which can reduce the height of the vehicle.

[0013] The upper frame 2 is embedded in the lower frame 5 with gaps. The height of the vehicle can be further reduced.

[0014] The scissors support 4 includes front and rear two pairs of struts hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com