Stacked crimping packaging structure of silicon carbide DSRD

A packaging structure and stacking technology, applied in the field of device packaging, can solve the problems of thermal mismatch partial discharge, unreliability, etc., achieve the effects of reducing electrical connections, improving reliability, and solving reliability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

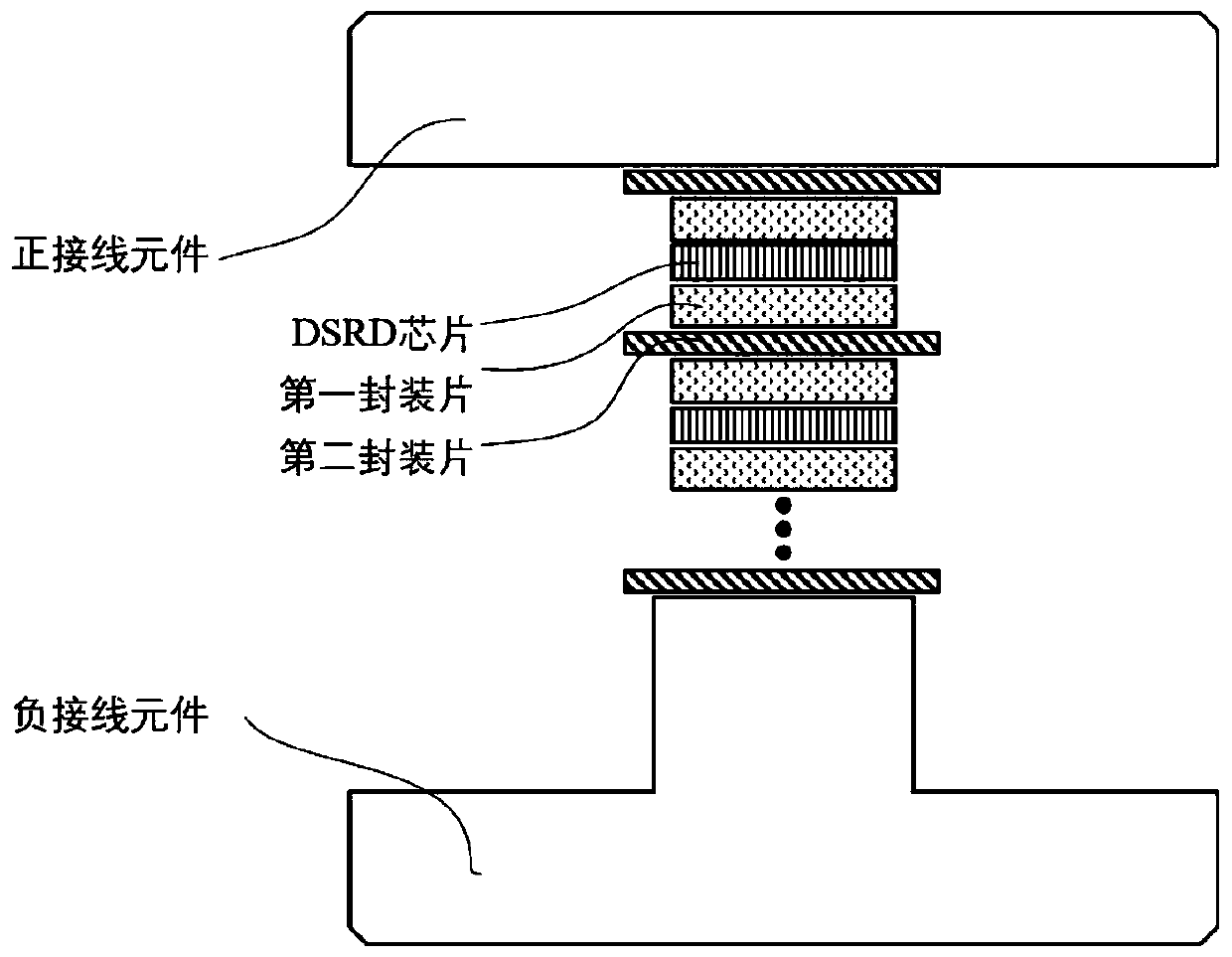

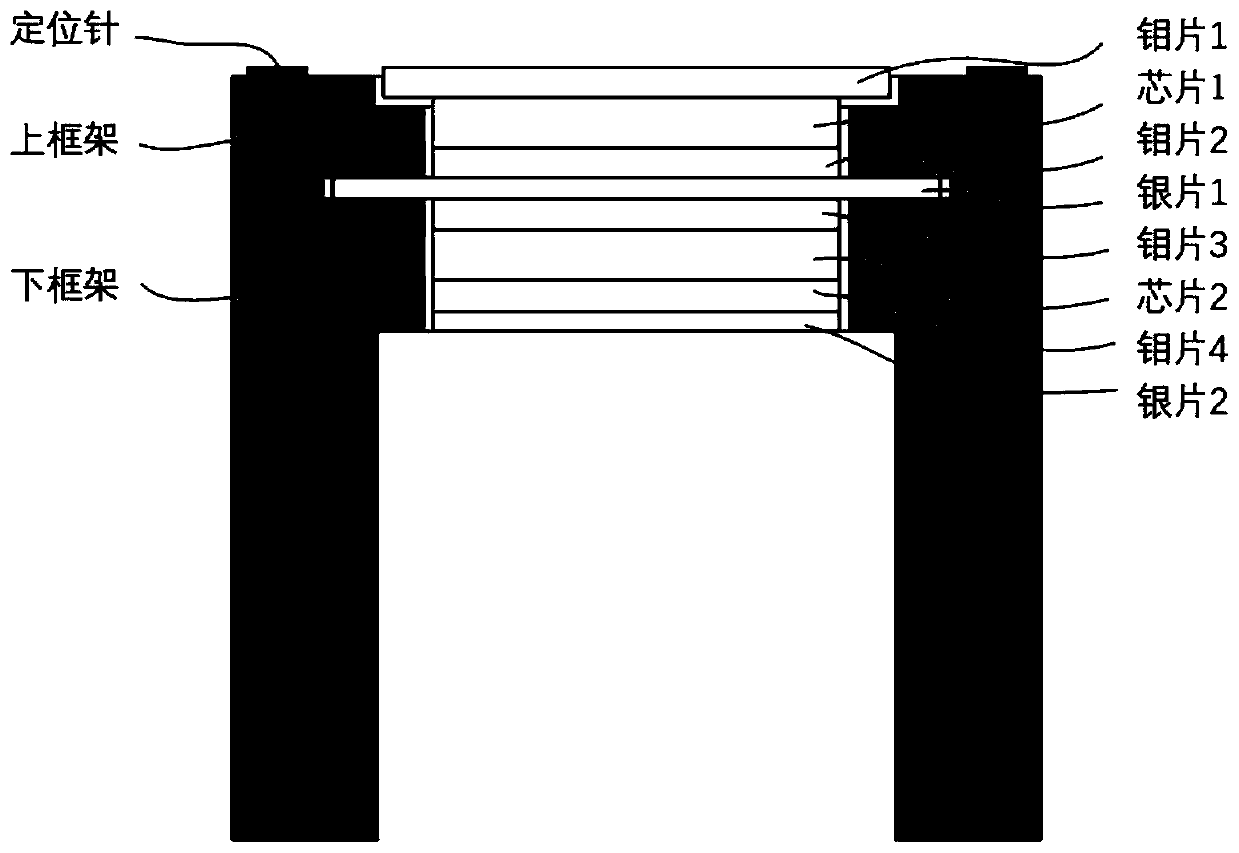

[0033] A stacked press-fit package structure of SiC DSRD, such as figure 1 As shown, it includes: a plurality of first packaging chips, a plurality of second packaging chips, a plurality of DSRD chips, and positive and negative wiring elements.

[0034] Among them, the DSRD chip is a silicon carbide chip, and a layer of first packaging sheets is stacked on both sides of each DSRD chip to form a packaging sub-module; a layer of second packaging sheets is stacked between each adjacent two packaging sub-modules to form a The vertical structure of stacked crimping; in this vertical structure, each adjacent two layers are connected by pressure to realize the electrical connection between each two DSRD chips, and the positive and negative wiring elements are respectively connected to the positive and negative ends of the vertical structure . The material of the first packaging sheet matches the thermal expansion coefficient of the DSRD chip material to avoid thermal deformation cau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com