Magnetic valve type controllable reactor wireless temperature state monitoring system and method

A condition monitoring system, wireless temperature technology, applied in thermometers, thermometers using electrical/magnetic components directly sensitive to heat, information technology support systems, etc., can solve problems such as high cost, shedding, decomposition, and disadvantageous high-voltage insulation, Achieve the effect of low installation and post-maintenance costs, prevention of serious accidents, and reduction of electrical wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

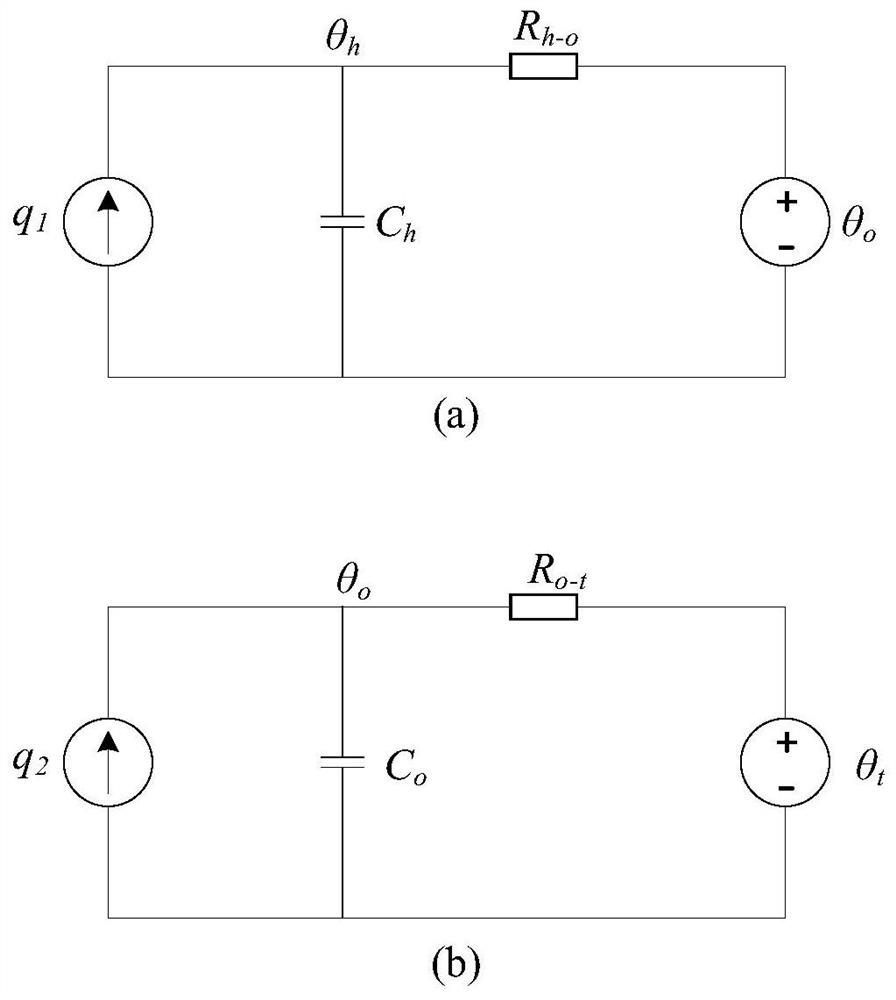

Method used

Image

Examples

Embodiment 1

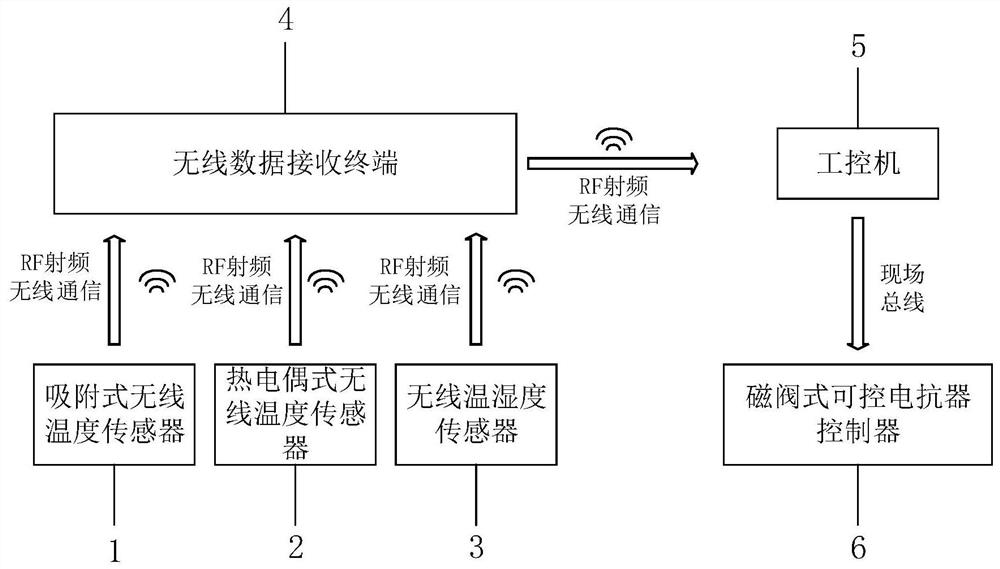

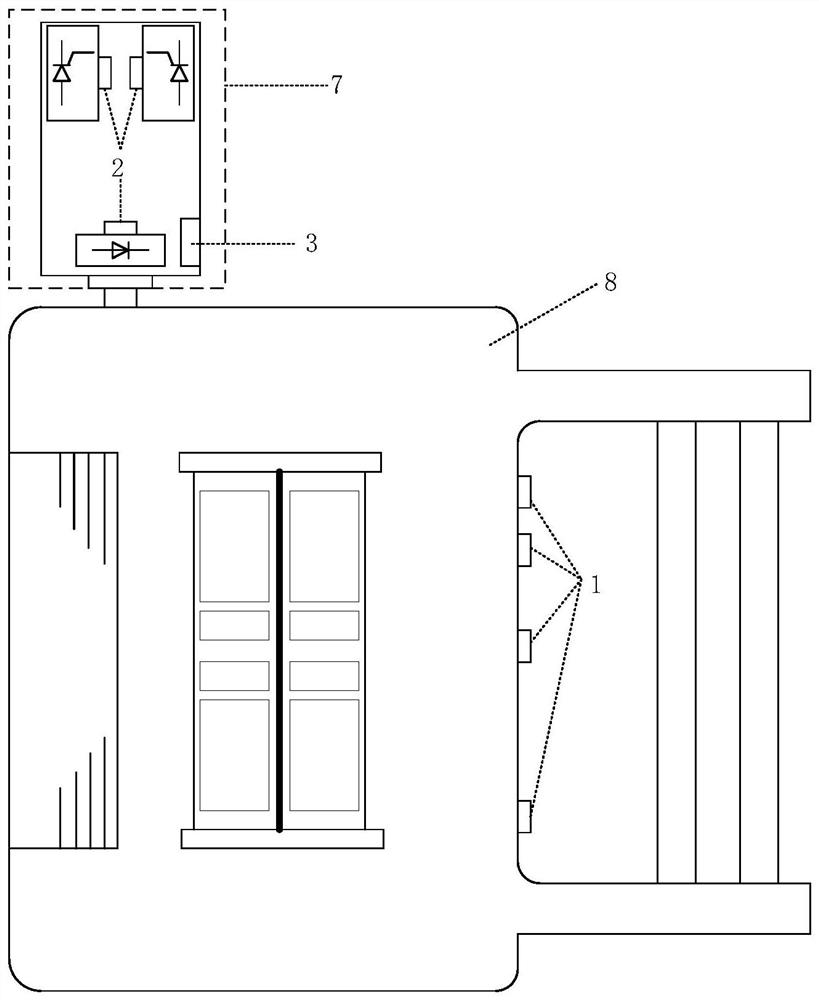

[0048] This embodiment provides a magnetic valve type controllable reactor wireless temperature state monitoring system, such as figure 2 , 3 As shown, it includes an adsorption wireless temperature sensor 1 , a thermocouple type wireless temperature sensor 2 , a wireless temperature and humidity sensor 3 , a wireless data receiver 4 , an industrial computer 5 and a magnetic valve type controllable reactor controller 6 . Among them, the adsorption wireless temperature sensor 1 is adsorbed on the high temperature heating point on the magnetic valve type controllable reactor cabinet body 8, and the thermocouple type wireless temperature sensor 2 is placed on the high temperature heating point on the thyristor and diode heat sink in the excitation cabinet 7; the wireless The temperature and humidity sensor 3 is placed in the excitation cabinet 7 of the magnetic valve type controllable reactor; each sensor collects on-site data, and uploads the data to the wireless data receiving...

Embodiment 2

[0050] This embodiment provides a magnetic valve type controllable reactor wireless temperature state monitoring method, such as Figure 4 As shown, it includes the steps:

[0051] 1) Use the adsorption wireless temperature sensor, thermocouple wireless temperature sensor and wireless temperature and humidity sensor to measure the temperature at the high temperature heating point of the MCR box, the temperature at the high temperature of the thyristor and diode heat sink, and the temperature and humidity inside the excitation cabinet in real time, respectively, and Upload the temperature and humidity data to the wireless data receiving terminal through RF wireless communication;

[0052] 2) the wireless receiving terminal packs after receiving the data of the sensor, and transmits the data to the industrial computer through the RF radio frequency wireless communication mode;

[0053] 3) The industrial computer processes the received data, and monitors the real-time temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com