Shaft sleeve for simulating supercritical CO2 fracturing sample and use method

A supercritical and fracturing technology, applied in wellbore/well components, teaching models, earth-moving drilling and production, etc., can solve the problem of inability to achieve single-stage multi-perforation fracturing, etc., to improve accuracy, sealing effect, test Easy operation and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

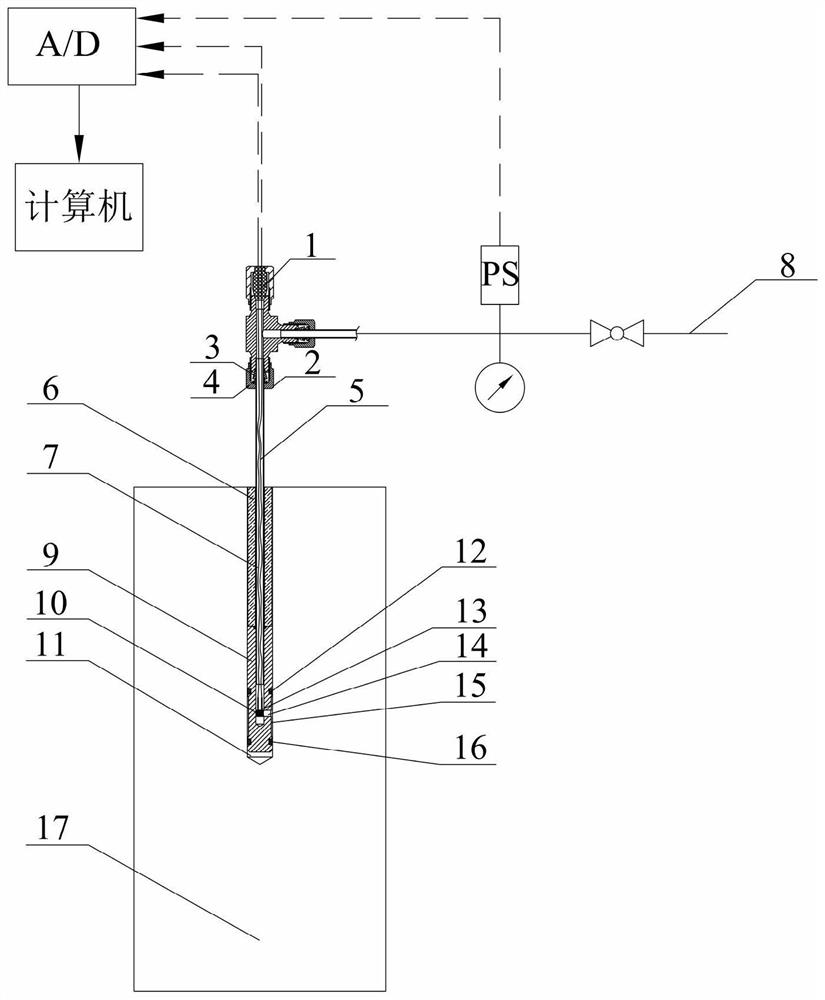

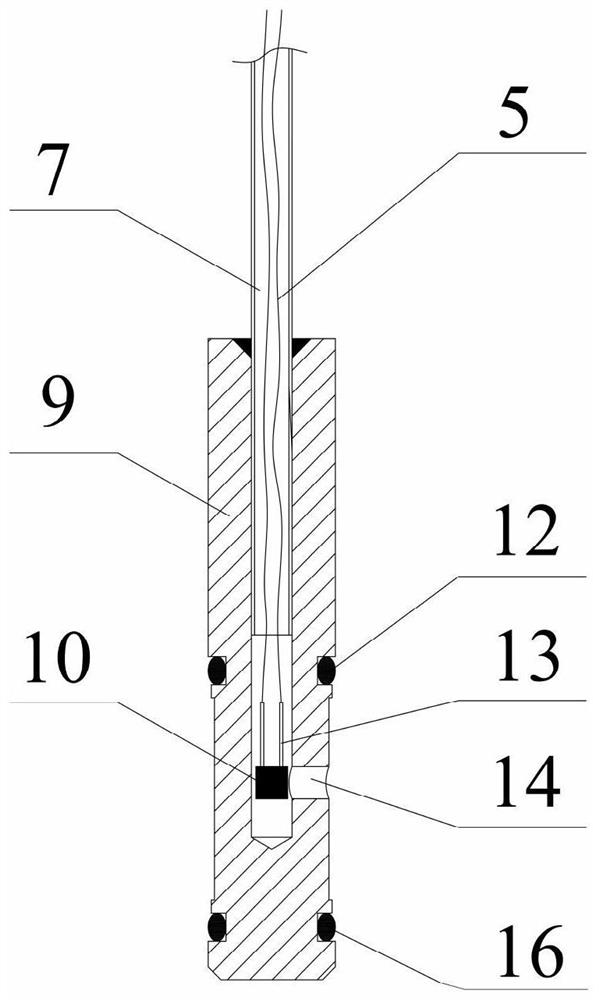

[0034] like figure 1 , 2 shown, for simulating supercritical CO 2 The wellbore casing of the single-section annular chamber of the fracturing sample includes an outer pipe 9, a central liquid injection pipe 7, a seal and a miniature temperature sensor. The outer tube 9 is made of high-pressure resistant stainless steel; the outer diameter of the outer tube 9 is adapted to the diameter of the central borehole 11 of the sample 17; the channel of the central liquid injection tube 7 is drilled along the central axis of the outer tube 9 , the channel diameter is 3.2mm, and the bottom of the channel is 10mm away from the bottom of the outer tube 9; the groove depth of the upper annular groove 12 and the lower annular groove 16 is 1.4mm, and the groove width is 2.2mm. The outer diameters of the upper annular groove 12 and the lower annular groove 16 are the same as the outer diameter of the outer tube 9, and the inner diameter is larger than the outer diameter of the central liquid...

Embodiment 2

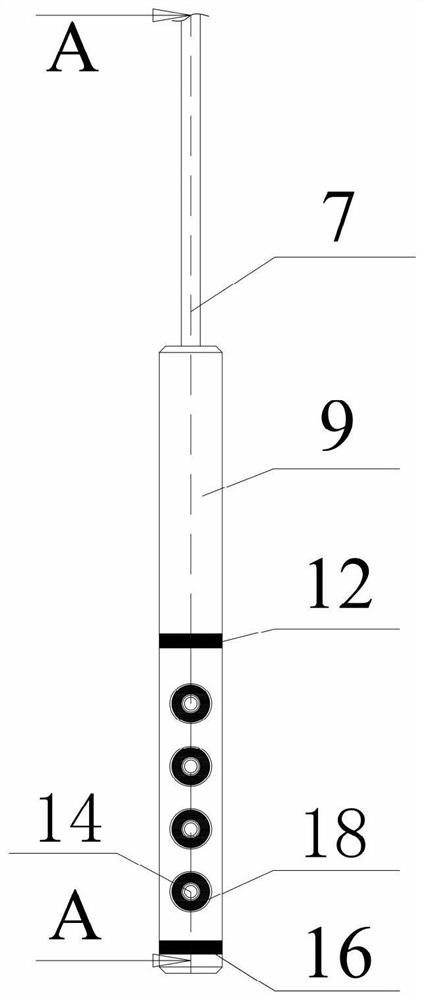

[0042] like image 3 , 4 As shown, the difference from Embodiment 1 is that the wellbore casing with single-segment straight rows and multiple perforations: at the position d1 from the upper end face of the lower annular groove 16 of the outer pipe 9, The side wall is provided with the first circular groove 18, and based on the position of the first circular groove 18, move up along the axis direction (d1+h) to open the second round groove 18; similarly, move up along the axis direction (d1 +2h) position to open a third circular groove 18, move up along the axis direction (d1+3h) to open a fourth circular groove 18, and in the first circular groove 18, the second circular groove 18, the third A fifth circular groove 18 , a sixth circular groove 18 , a seventh circular groove 18 , and an eighth circular groove 18 are provided in a linear array opposite the circular groove 18 and the fourth circular groove 18 . Wherein, the outer diameter of each circular groove 18 is R1, the ...

Embodiment 3

[0044] like Figure 5 , 6 As shown, the difference from Example 1 is that the single-stage helical multi-perforated wellbore casing: the position away from the upper end surface d1 of the lower annular groove 16 of the outer pipe 9 is on the side of the outer pipe 9 The first circular groove 18 is opened on the wall, and based on the position of the first circular groove 18, move up (d1+h) along the axis direction and rotate 90° counterclockwise in the radial direction to open the second circular groove 18; similarly , move up along the axis direction (d1+2h) and rotate counterclockwise 90° radially to open the third round groove 18, move up along the axis direction (d1+3h) and rotate 90° counterclockwise radially to open the fourth circular groove 18 18 round grooves. Wherein, the outer diameter of each circular groove 18 is R1, the inner diameter is R2, and the center of each circular groove 18 is drilled with a liquid injection hole 14 whose diameter is smaller than R2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com