Supercritical carbon dioxide recompression cycle power generation system and operation method

A carbon dioxide, cyclic power generation technology, applied in machines/engines, steam engines, mechanical equipment, etc., can solve problems such as inability to adjust, and achieve the effect of reducing failure rate, wide application range, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

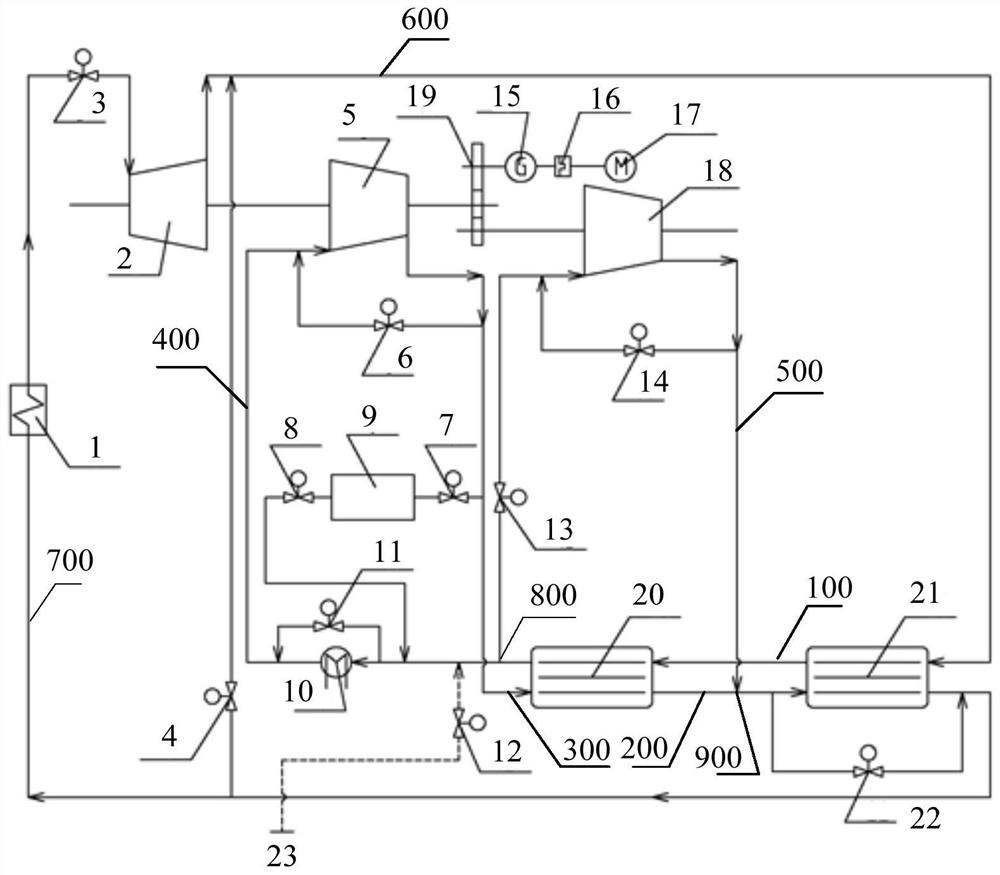

[0034] see figure 1 As shown, the embodiment of the present application provides a supercritical carbon dioxide recompression cycle power generation system, including: a heat exchange path, a first compression path 400, a second compression path 500, a heat absorption path 700, a work output path 600 and a return path Heat path 300; wherein, the heat exchange path includes a first heat exchange path 100 and a second heat exchange path 200; the first compression path 400 is arranged in parallel with the second compression path 500 and forms the same input end 800, and the first compression path 400 merges with the second compression path 500 via the heat recovery path 300 and forms the same output end 900;

[0035] The output end of the first heat exchange path 100 is connected with the same input end 800, and the same output end 900 is connected with the input end of the second heat exchange path 200; the output end of the second heat exchange path 200, the heat absorption pat...

Embodiment 2

[0068] Embodiments of the present application also provide a method for operating a supercritical carbon dioxide recompression cycle power generation system, which is applied to the supercritical carbon dioxide recompression cycle power generation system in any of the above embodiments, including the following steps (the symbols therein refer to Embodiment 1) :

[0069] When the supercritical carbon dioxide recompression cycle power generation system is running at reduced load, the speed of each rotating part remains unchanged, open the turbine bypass valve 4 and gradually close the valve port of the turbine throttle valve 3, so that a part of the working fluid passes through the flow bypass It flows to the outlet of turbine 2 and mixes with its exhaust gas; when the supercritical carbon dioxide recompression cycle power generation system is operating with increased load, the speed of each rotating part remains unchanged, and the turbine bypass valve 4 is closed and the turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com