Automatic drainage valve with fault detection function

An automatic drainage and fault detection technology, which is applied in the direction of functional valve type, lifting valve, valve details, etc., can solve the problems of increasing the workload of use and maintenance, failure to detect and feedback the fault of the drain valve, and no drainage signal feedback of the automatic drain valve. Achieve the effects of good reliability, automation, energy saving, and high automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

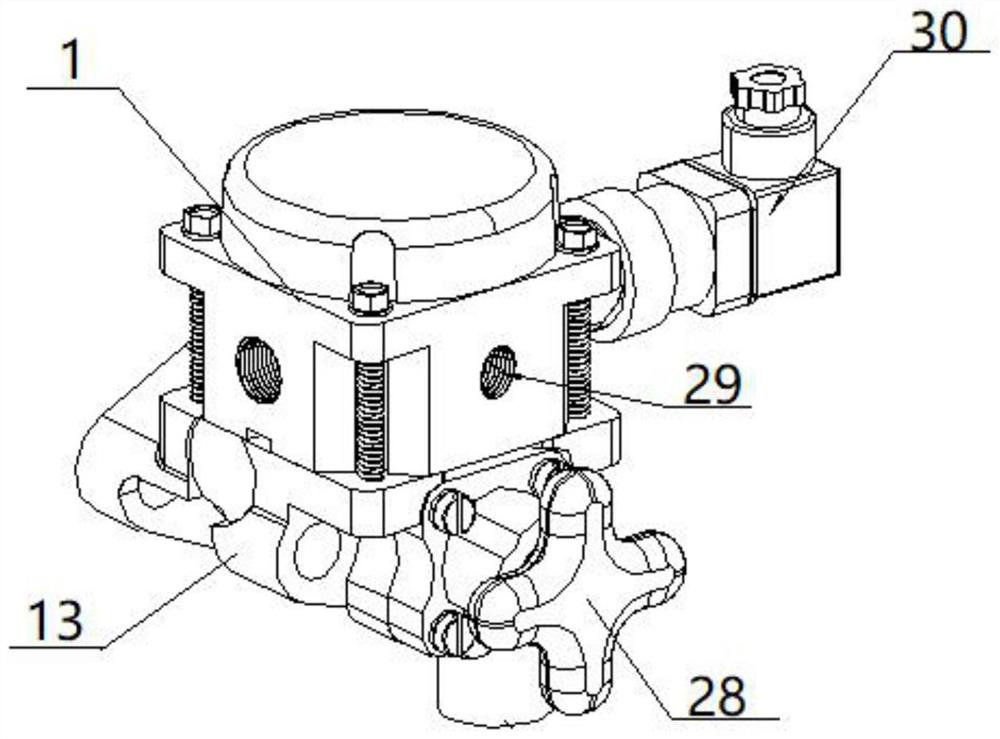

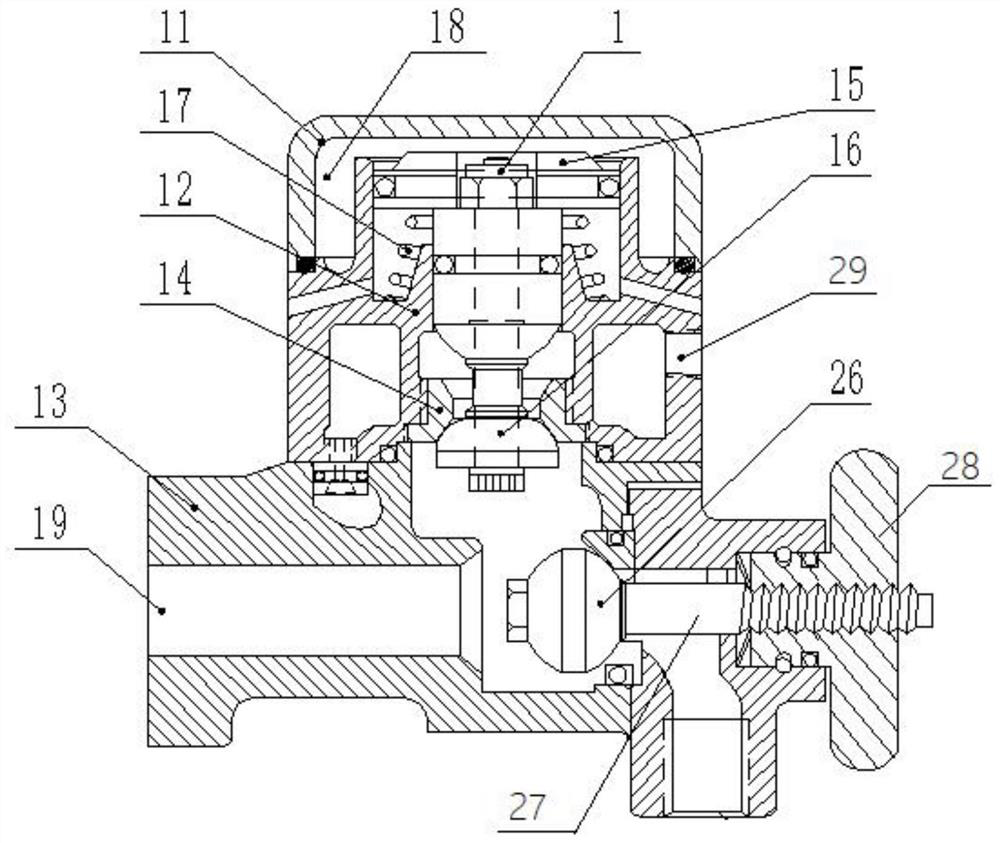

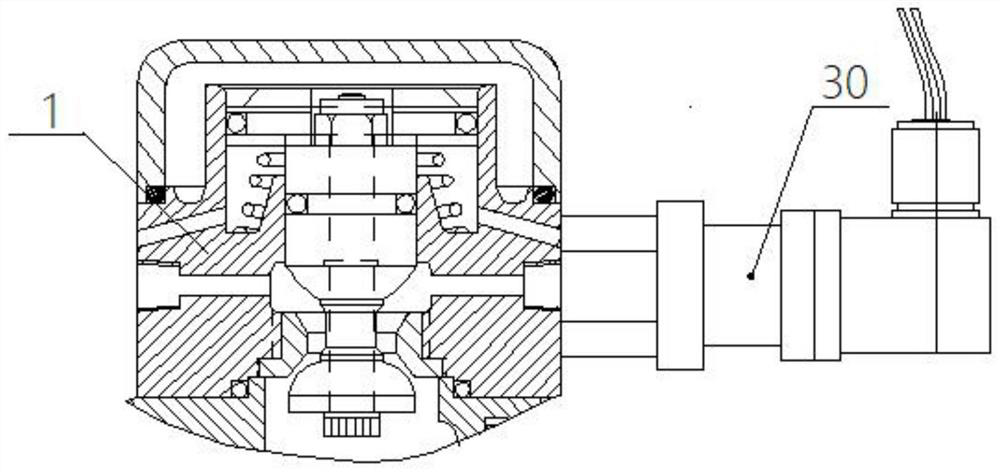

[0017] see Figure 1 to Figure 4 , an automatic drain valve with fault detection function, including a valve body assembly 1 and a pressure switch 26, the valve body assembly 1 includes a valve body 12, a piston assembly 15, a spring 17, a valve core seat 14, a valve 16 and a valve cover 11 The valve body is provided with an installation groove, the valve cover is arranged on the top of the valve body, an air cavity 18 is formed between the valve cover 11 and the valve body 12, the air cavity communicates with the installation groove of the valve body, and the piston assembly is arranged in the installation groove. The piston assembly is covered with a spring, the piston assembly is provided with a through groove, the bottom of the through groove is provided with a valve core seat, the valve core seat is provided with a water outlet hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com