Impact test device and experimental method based on spatial motion sandwich plate structure

A technology of space motion and impact testing, applied in the testing of machine/structural components, impact testing, measuring devices, etc., can solve the problems of impact response behavior test simulation of composite sandwich panel structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

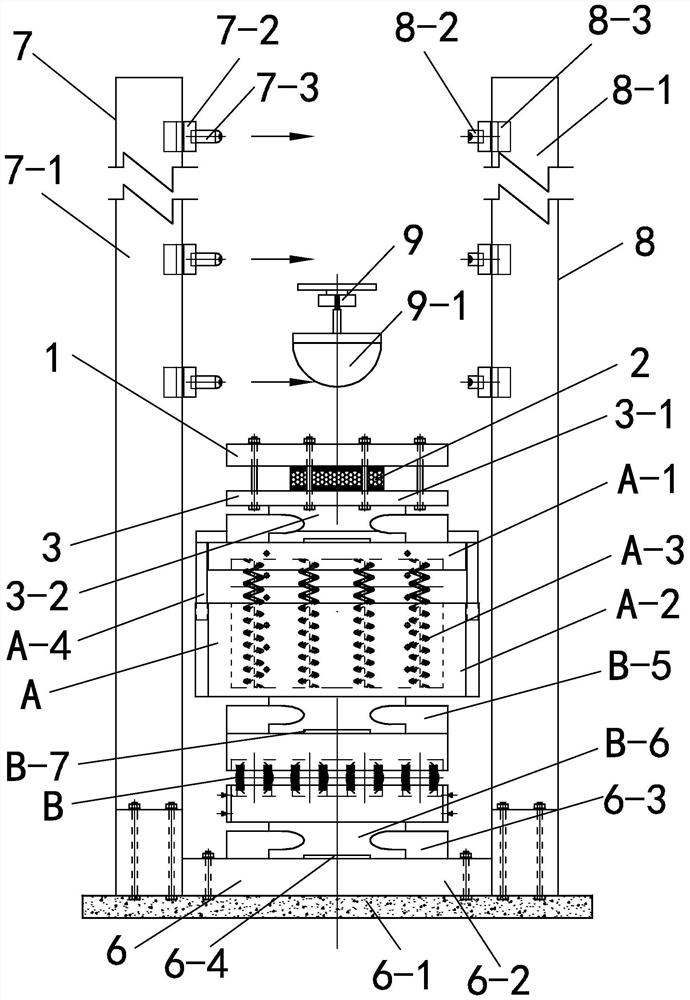

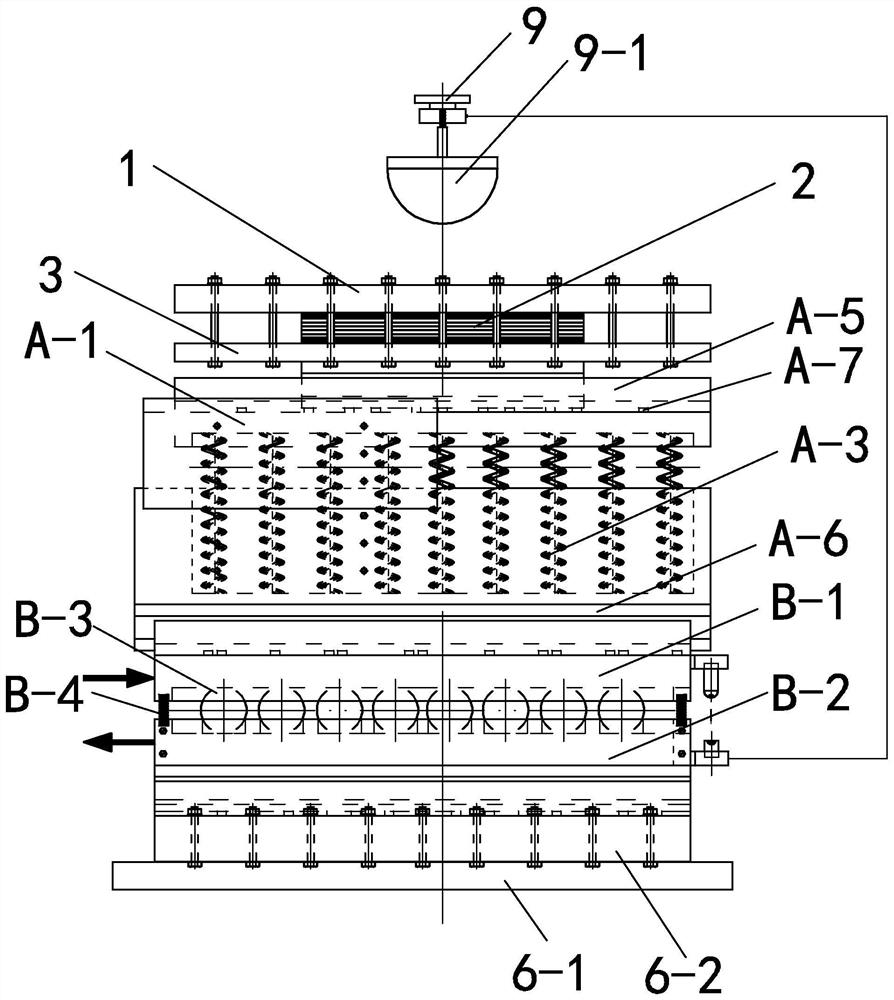

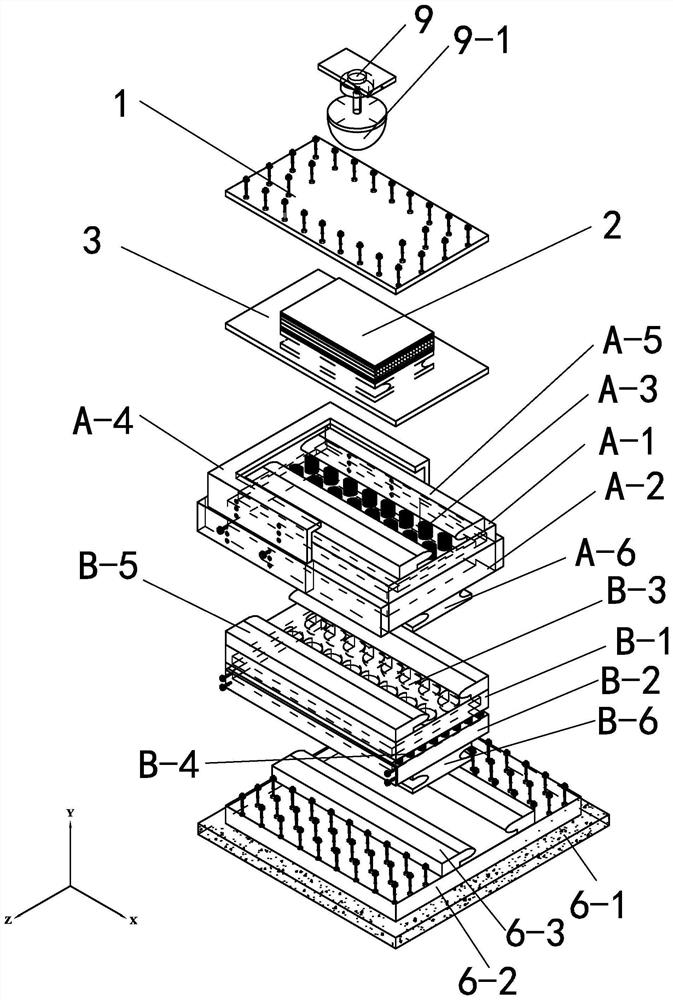

[0033] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a kind of impact test device based on the space movement sandwich plate structure of this embodiment includes upper mounting splint 1, lower mounting splint 3, vertical plane vibration device A, horizontal plane motion device B, experimental base 6, signal The generating device 7 and the signal receiving device 8, the signal generating device 7 and the signal receiving device 8 are relatively arranged and installed on the experimental base 6, the horizontal plane moving device B is inserted on the experimental base 6, and the horizontal plane moving device B is located on the Between the signal generating device 7 and the signal receiving device 8, the vertical plane vibrating device A is plugged into the horizontal plane moving device B, the upper mounting splint 1 and the lower mounting splint 3 are buckled and the composite sandwich plate 2 is clamped, and the lower mounting spli...

specific Embodiment approach 2

[0041] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the lower mounting splint 3 of this embodiment includes a lower splint 3-1 and a splint chute 3-2, and the splint chute 3-2 is fixedly installed on the lower end surface of the lower splint 3-1. Such setting facilitates cooperation and sliding insertion with the vertical plane vibration device A. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific implementation mode three: combination Figure 1 to Figure 3 Describe this embodiment, the vertical plane vibration device A of this embodiment includes an upper connection cover A-1, a lower connection cover A-2, a stopper A-4 and a plurality of vibration springs A-3, the lower connection cover A-2 A groove is opened in A-2, and multiple vibrating springs A-3 are installed in the lower connecting cover A-2, and the upper connecting cover A-1 is covered on multiple vibrating springs A-3, and the upper connecting cover A- 1 and the lower connection cover A-2 are connected by a stopper A-4, and the upper connection cover A-1 is located in the stopper A-4 and can float up and down under the action of the vibration spring A-3. Such arrangement facilitates vibration in the vertical direction. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0043] The setting of the limiter in this embodiment ensures that the test structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com