Flow cooperative control method and control system device for shift gas and unshifted gas of gasification furnace

A collaborative control and system device technology, applied in the direction of flow control, non-electric variable control, control/adjustment system, etc., can solve the problems of manual intervention, many factors to be considered, and untimely adjustment, so as to reduce the amount of operation and overcome Coupling, the effect of avoiding fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

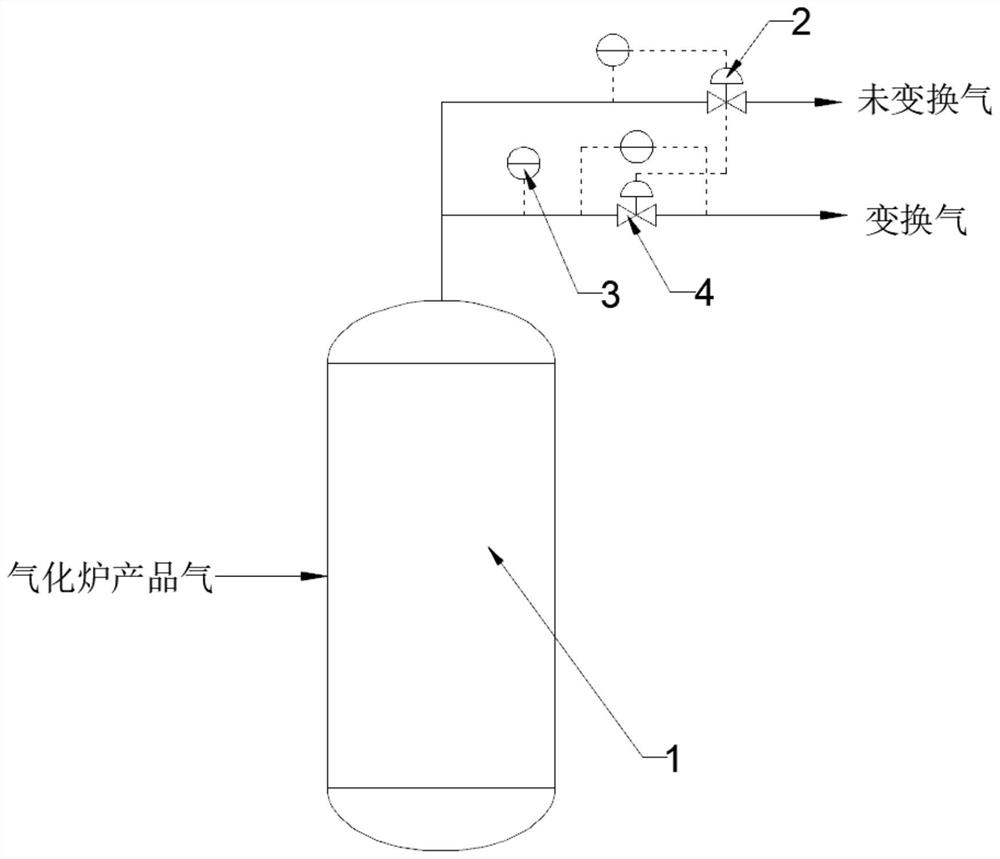

[0076] The conversion air flow rate of the flow coordination control system device is 290000Nm 3 / h, the unchanging gas flow is 250000Nm 3 / h, at this time, the unconverted gas flow regulating valve position fluctuates at 48-52%, and the transformed gas regulating valve 4 fluctuates around 60%.

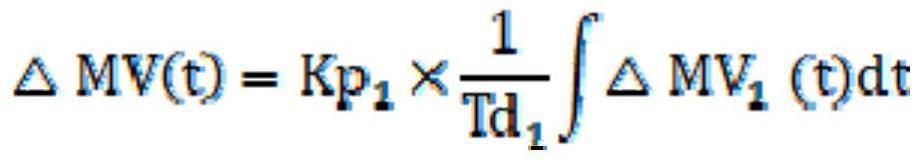

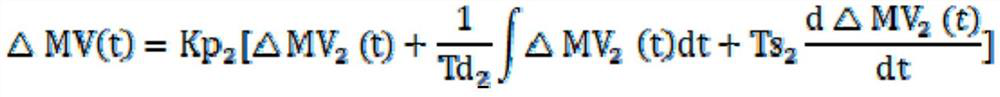

[0077] The effective adjustment range of the unchanged air flow regulating valve position is 20-80%, that is, the upper limit of the effective adjustment range Max is 80%, the lower limit of the effective adjustment range is 20%, and the actual value MV of the unchanged air flow regulating valve position is 1 (48-52%) In the effective adjustment interval (20-80%), the setting value a of the unchanging air flow adjustment valve position is 50% (the middle value of the effective adjustment interval), according to the real-time read MV 1 The deviation between value and a value ΔMV 1 (t), the converted gas regulating valve 4 controls the valve position of the unconverted gas flow throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com