Heat dissipation type cable bridge with cable isolation function

A cable tray and heat dissipation technology, applied in the direction of electrical components, etc., can solve the problems of easy interleaving of cables, scattered wiring, increased power line loss, etc., to achieve the effect of facilitating maintenance and heat dissipation, avoiding heat accumulation and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

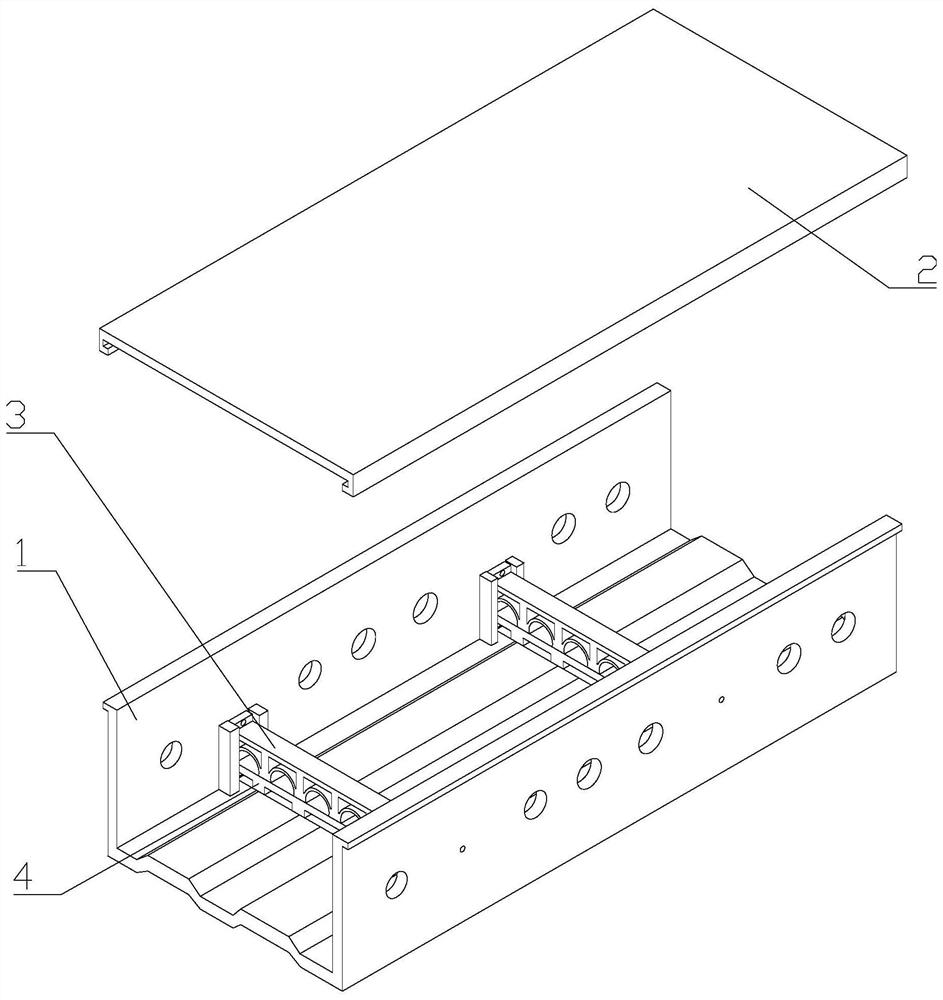

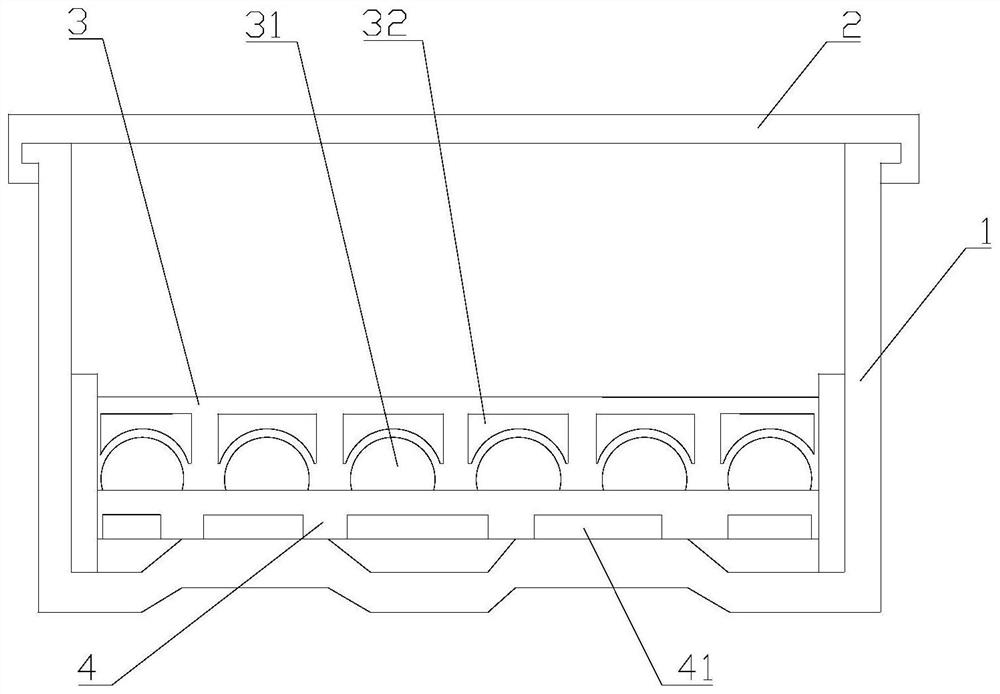

[0015] refer to figure 1 and figure 2 , the present invention proposes a heat-dissipating cable bridge with cable isolation function, comprising: a cable bridge 1, a cover plate 2 and one or more sets of cable isolation components;

[0016] The cover plate 2 and the cable tray 1 are detachably and fixedly connected. The side wall of the cable tray 1 is symmetrically provided with a plurality of cooling holes. Extending in the length direction, multiple sets of cable isolation components are arranged in the cable tray 1 at intervals along the length direction of the cable tray 1;

[0017] The two side walls of the cable tray 1 are symmetrically provided with socket slots corresponding to each group of cable isolation components. The cable isolation components include support plates 4 and isolation plates 3, and the support plates 4 and isolation plates 3 are arranged along the width direction of the cable tray 1. , and the isolation plate 3 and the support plate 4 are sequen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap