Ceramic tile gluing device and method and paving and pasting equipment

A gluing device and ceramic tile technology, which is applied to the surface coating liquid device, coating, construction, etc., can solve the problems of not obvious improvement effect of tile paving, pipeline blockage cleaning, low degree of automation, etc., to achieve reduction The effect of small horizontal occupation area, avoiding collision and improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

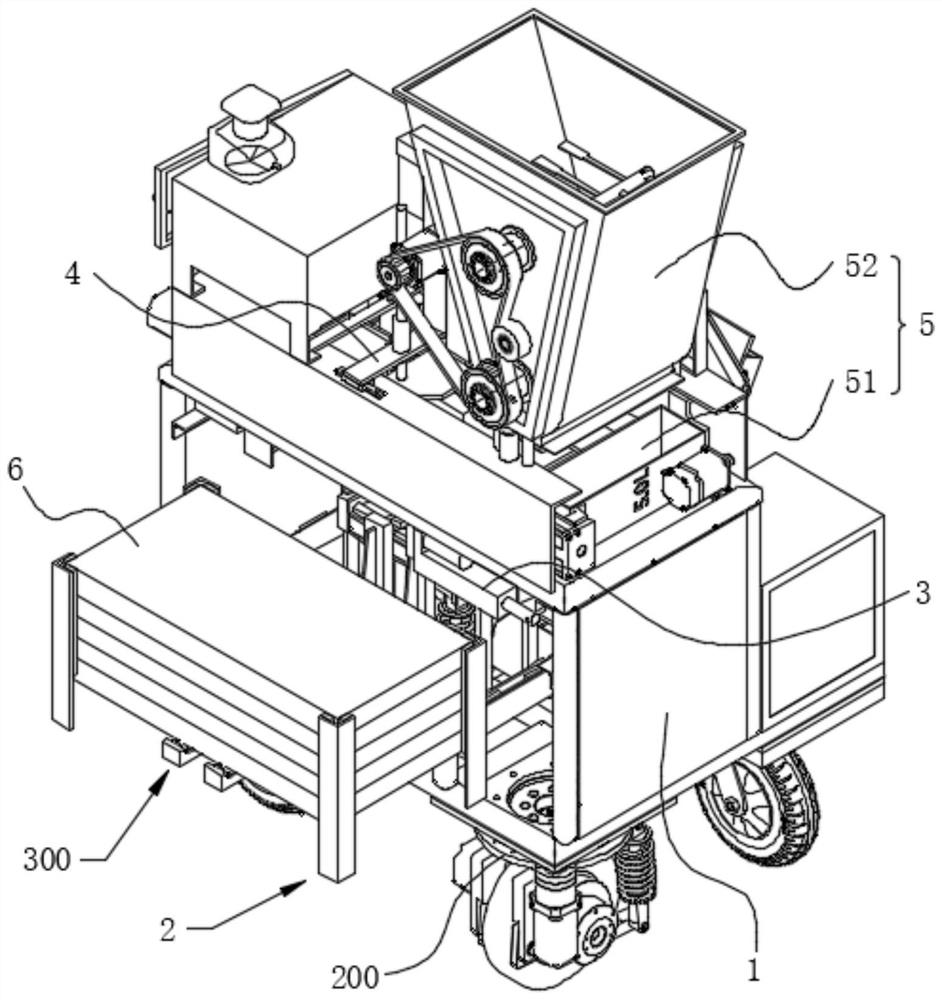

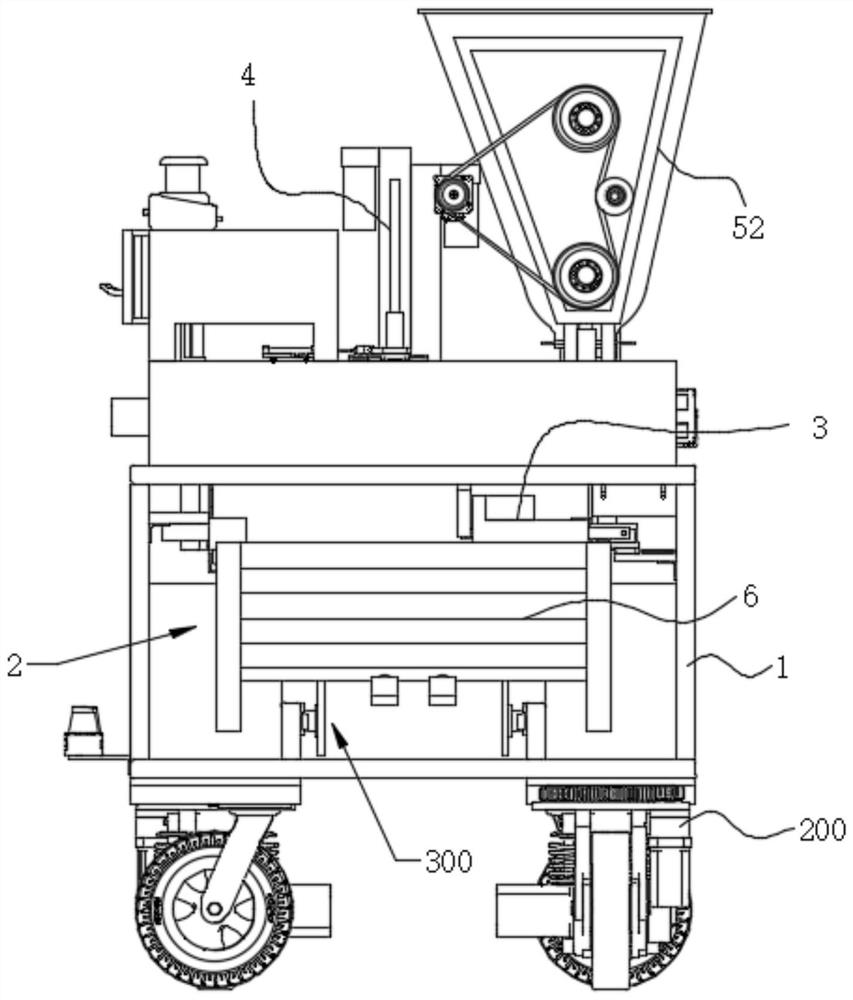

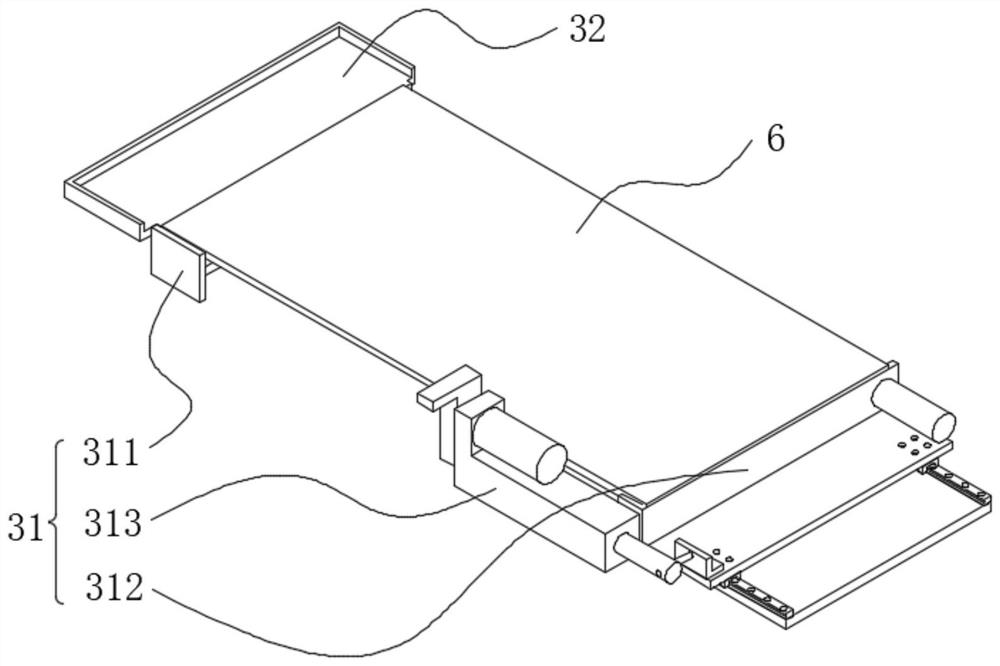

[0097]A tile gluing device, such as Figure 1 to Figure 3 As shown, it includes a frame 1, a carrying conveying mechanism 3, a lifting and grabbing mechanism 4 and a gluing mechanism 5. The inside of the rack 1 is provided with a tile storage area for placing tiles to be glued. The carrying conveying mechanism 3 is installed on the frame 1 and is positioned above the ceramic tile storage area. The carrying and clamping platform 31 of the carrying conveying mechanism 3 includes two clamping plates for carrying and limiting the tiles 6 to be glued. Openings are formed between the clamping plates, at least one of the clamping plates can move relative to the other clamping plate. The lifting and grabbing mechanism 4 is installed on the frame 1, and the lifting and grabbing mechanism 4 can move along the height direction and pass through the opening of the loading and clamping platform 31, for grabbing the tiles 6 from the tile storage area and placing them on the loading and clam...

Embodiment 2

[0116] A tile gluing method can be applied to the tile gluing device in Embodiment 1, so as to control the gluing device to perform gluing operations. Specifically, the ceramic tile gluing method of the present embodiment comprises the following steps:

[0117] S10, the lifting and grabbing mechanism 4 grabs the ceramic tile 6 to be glued from below the loading and clamping platform 31, and transfers the tile 6 to the top of the loading and clamping platform 31;

[0118] S20. The movable end of the bearing and clamping platform 31 moves horizontally toward the direction close to the tiles, and the lifting and grabbing mechanism 4 drives the tiles 6 to move horizontally in a direction away from the movable end, so that the side of the tiles 6 away from the movable end is located on the fixed side of the bearing and clamping platform 31. above the end, and the side of the tile 6 near the movable end is still above the movable end;

[0119] S30, the lifting and grabbing mechanis...

Embodiment 3

[0140] A tile laying equipment, including a laying robot arm, and a tile gluing device according to Embodiment 1. The laying robot arm is installed on a frame 1, and is used for grabbing glued tiles 6 and laying the tiles 6 on the target work surface. By setting the paving and pasting robot arm, it is possible to realize the full automation of gluing and paving of the ceramic tile 6, and improve the overall operation efficiency.

[0141] like Figure 14 and Figure 15 As shown, the tile laying equipment also includes a mobile chassis 200 on which the frame 1 is installed.

[0142] In this embodiment, the tile bin 2 is detachably connected to the frame 1, and the tile laying equipment also includes a bin conveying device 300, which is installed on the frame 1, and is used to transport the fully loaded tile bin 2 Transfer from outside the machine to the rack 1 or transfer empty tile bins 2 from the rack 1 to the outside of the machine. Specifically, by setting the bin convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com