Honeycomb type wine brewing condenser

A technology of honeycomb and condenser, which is applied in the field of cooling and honeycomb brewing condenser, which can solve the problems of increasing the maintenance cost and production cost of the cooling process, increasing the space occupied by the pipeline for conveying steam, and not being able to fully utilize the coolant, etc. , to achieve good cooling effect, rapid cooling, and miniaturized volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

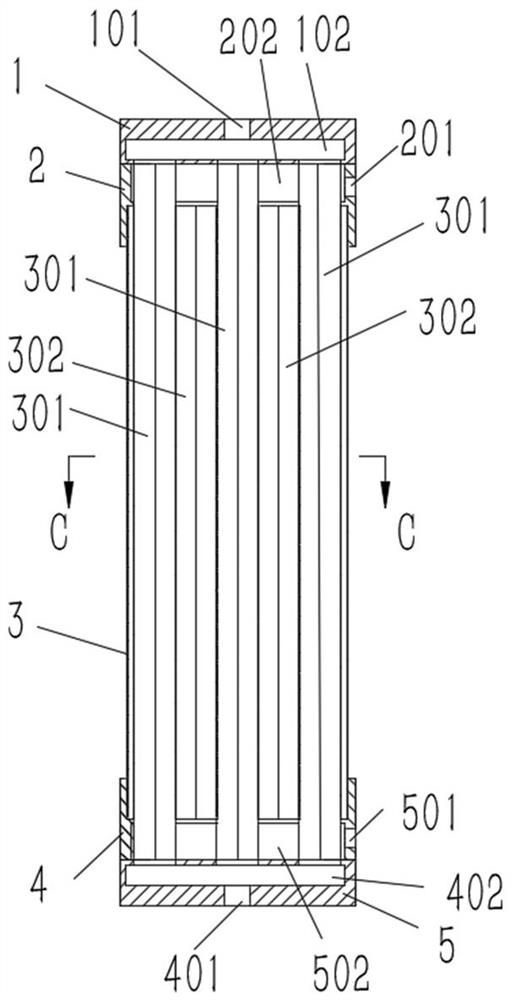

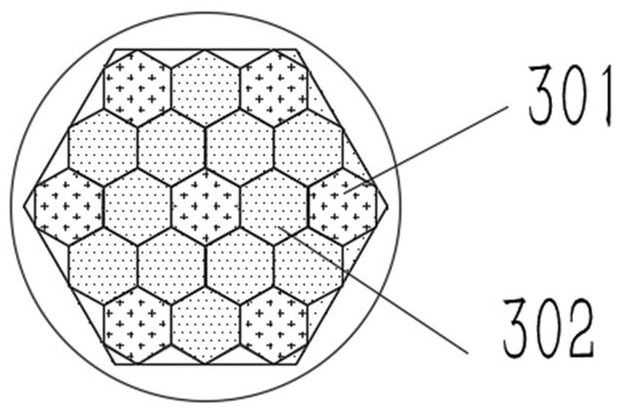

[0034] like figure 1 and figure 2As shown, a honeycomb brewing condenser, according to the installation position relationship from top to bottom, includes stainless steel steam upper valve body 1, stainless steel condensing upper valve body 2, stainless steel honeycomb condensing module 3, stainless steel steam lower valve body 4 and stainless steel Condensing lower valve body 5, steam upper valve body 1 is provided with steam inlet 101, condensing upper valve body 2 is provided with condensing outlet 201, steam lower valve body 4 is provided with outlet 401, condensing lower valve body 5 is provided with condensing inlet 501, honeycomb condensation The module 3 includes a steam flow channel 301 and a condensation flow channel 302. The upper end of the steam flow channel 301 is connected to the steam upper valve body 1, the lower end of the steam flow channel 301 is connected to the steam lower valve body 4, and the condensation flow channel 302 The upper end is connected to...

Embodiment 2

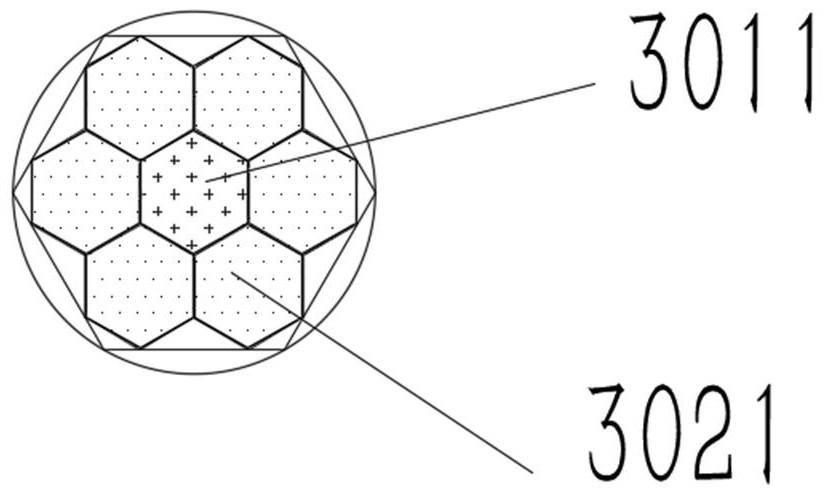

[0036] like figure 1 and image 3 As shown, a honeycomb brewing condenser includes a plastic steam upper valve body 1, a plastic condensing upper valve body 2, a plastic honeycomb condensing module 3, a plastic steam lower valve body 4 and a plastic Condensing lower valve body 5, steam upper valve body 1 is provided with steam inlet 101, condensing upper valve body 2 is provided with condensing outlet 201, steam lower valve body 4 is provided with outlet 401, condensing lower valve body 5 is provided with condensing inlet 501, honeycomb condensation Module 3 includes a steam flow channel A3011 and a condensation flow channel A3021, the upper end of the steam flow channel A3011 is connected to the steam upper valve body 1, the lower end of the steam flow channel A3011 is connected to the steam lower valve body 4, and the condensation flow channel A3021 The upper end is connected to the condensing upper valve body 2, and the lower end of the condensing flow channel A3021 is con...

Embodiment 3

[0041] like figure 1 and Figure 4 As shown, a honeycomb brewing condenser, according to the installation position relationship from top to bottom, includes stainless steel steam upper valve body 1, stainless steel condensing upper valve body 2, stainless steel honeycomb condensing module 3, stainless steel steam lower valve body 4 and stainless steel Condensing lower valve body 5, steam upper valve body 1 is provided with steam inlet 101, condensing upper valve body 2 is provided with condensing outlet 201, steam lower valve body 4 is provided with outlet 401, condensing lower valve body 5 is provided with condensing inlet 501, honeycomb condensation Module 3 includes a steam flow channel B3012 and a condensation flow channel B3022, the upper end of the steam flow channel B3012 is connected to the steam upper valve body 1, the lower end of the steam flow channel B3012 is connected to the steam lower valve body 4, and the condensation flow channel B3022 The upper end is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com