Air brick prepared based on isostatic cool pressing wet bag method, and preparation method of air brick

A technology of cold isostatic pressing and breathable bricks, applied in the field of breathable brick preparation, can solve the problems of quality fluctuation and particle segregation of breathable bricks, and achieve the effect of uniform and stable air permeability, sufficient air permeability and high thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

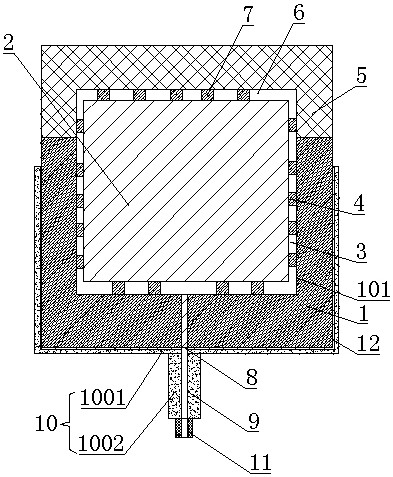

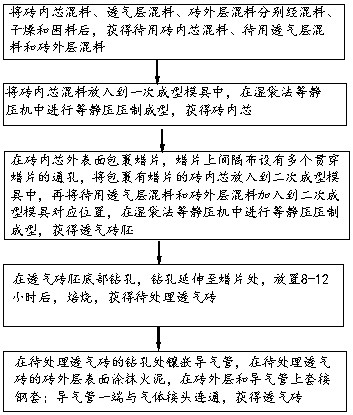

[0057] like figure 2 As shown, the present invention also provides a method for preparing the breathable brick based on the cold isostatic pressing wet bag method as described in any one of the above, comprising the following steps:

[0058] S1) After the brick inner core mixture, the breathable layer mixture and the brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0059] S2) Put the brick inner core mixture into a primary forming mold, perform isostatic pressing in a wet bag isostatic pressing machine, and obtain the brick inner core 2;

[0060] S3) Wrap the wax sheet on the outer surface of the brick inner core 2, and a plurality of through holes through the wax sheet are arranged at intervals on the wax sheet, put the brick inner core 2 wrapped with the wax sheet into the secondary molding mold, and then pl...

Embodiment 1

[0076] Based on the above basis, sample 1 was prepared, and the preparation steps were as follows:

[0077] 101) After the brick inner core mixture, air-permeable layer mixture and brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0078] Among them, the temperature when the material is trapped is 23°C-25°C; the time for trapping the material is 48h;

[0079] Among them, the volatile content of the air-permeable layer mixture to be used is 2.55%-2.65% at 160°C;

[0080] Among them, in terms of parts by weight, the air-permeable layer mixture includes 97 parts of fused magnesia, 13 parts of zircon mullite, 9 parts of fused quartz, 3 parts of calcined alumina micropowder, 1.5 parts of ferrosilicon nitride, and 5.5 parts of antioxidant , 5 parts of loss-of-ignition agent, 10 parts of thermosetting liquid resin, 1.5...

Embodiment 2

[0101] Based on the above basis, sample 2 was prepared, and the preparation steps were as follows:

[0102] 201) After the brick inner core mixture, air-permeable layer mixture and brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0103] Among them, the temperature when the material is trapped is 23°C-25°C; the time for trapping the material is 48h;

[0104] Among them, the volatile content of the air-permeable layer mixture to be used is between 2.55% and 2.65% at 160°C;

[0105] Among them, in terms of parts by weight, the air-permeable layer mixture includes 97 parts of fused magnesia, 13 parts of zircon mullite, 8 parts of fused quartz, 3 parts of calcined alumina micropowder, 1.5 parts of ferrosilicon nitride, and 5.5 parts of antioxidant , 5 parts of loss-of-burn agent, 9 parts of thermosetting liquid res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com