A kind of air permeable brick based on cold isostatic pressing wet bag method and its preparation method

A technology of cold isostatic pressing and air-permeable bricks, which is applied in the field of air-permeable brick preparation, which can solve problems such as quality fluctuation and particle segregation of air-permeable bricks, and achieve the effect of uniform and stable air flow, sufficient air flow, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

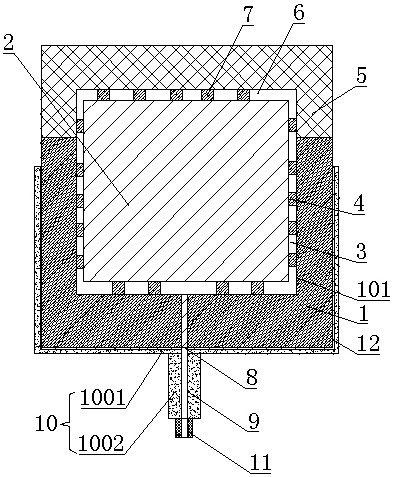

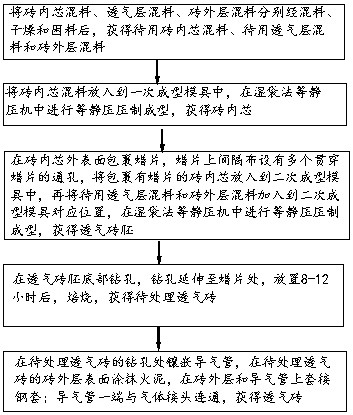

[0061] Such as figure 2 As shown, the present invention also provides a method for preparing the breathable brick based on the cold isostatic pressing wet bag method as described in any one of the above, comprising the following steps:

[0062] S1) After the brick inner core mixture, the breathable layer mixture and the brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0063] S2) Put the brick inner core mixture into a primary forming mold, perform isostatic pressing in a wet bag isostatic pressing machine, and obtain the brick inner core 2;

[0064] S3) Wrap the wax sheet on the outer surface of the brick inner core 2, and a plurality of through holes through the wax sheet are arranged at intervals on the wax sheet, put the brick inner core 2 wrapped with the wax sheet into the secondary molding mold, and then...

Embodiment 1

[0080] Based on the above basis, sample 1 was prepared, and the preparation steps were as follows:

[0081] 101) After the brick inner core mixture, air-permeable layer mixture and brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0082] Among them, the temperature when the material is trapped is 23°C-25°C; the time for trapping the material is 48h;

[0083] Among them, the volatile content of the air-permeable layer mixture to be used is 2.55%-2.65% at 160°C;

[0084] Among them, in terms of parts by weight, the air-permeable layer mixture includes 97 parts of fused magnesia, 13 parts of zircon mullite, 9 parts of fused quartz, 3 parts of calcined alumina micropowder, 1.5 parts of ferrosilicon nitride, and 5.5 parts of antioxidant , 5 parts of loss-of-ignition agent, 10 parts of thermosetting liquid resin, 1.5...

Embodiment 2

[0105] Based on the above basis, sample 2 was prepared, and the preparation steps were as follows:

[0106] 201) After the brick inner core mixture, air-permeable layer mixture and brick outer layer mixture are mixed, dried and trapped respectively, the ready-to-use brick inner core mixture, the ready-to-use air-permeable layer mixture and the brick outer layer mixture are obtained. material;

[0107] Among them, the temperature when the material is trapped is 23°C-25°C; the time for trapping the material is 48h;

[0108] Among them, the volatile content of the air-permeable layer mixture to be used is between 2.55% and 2.65% at 160°C;

[0109] Among them, in terms of parts by weight, the air-permeable layer mixture includes 97 parts of fused magnesia, 13 parts of zircon mullite, 8 parts of fused quartz, 3 parts of calcined alumina micropowder, 1.5 parts of ferrosilicon nitride, and 5.5 parts of antioxidant , 5 parts of loss-of-burn agent, 9 parts of thermosetting liquid res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com