Launching beam monitoring control construction method

A construction method and monitoring and control technology, applied in bridges, measuring devices, bridge construction, etc., can solve the problems of limited control range, cracking of the beam body, inaccuracy and precision, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

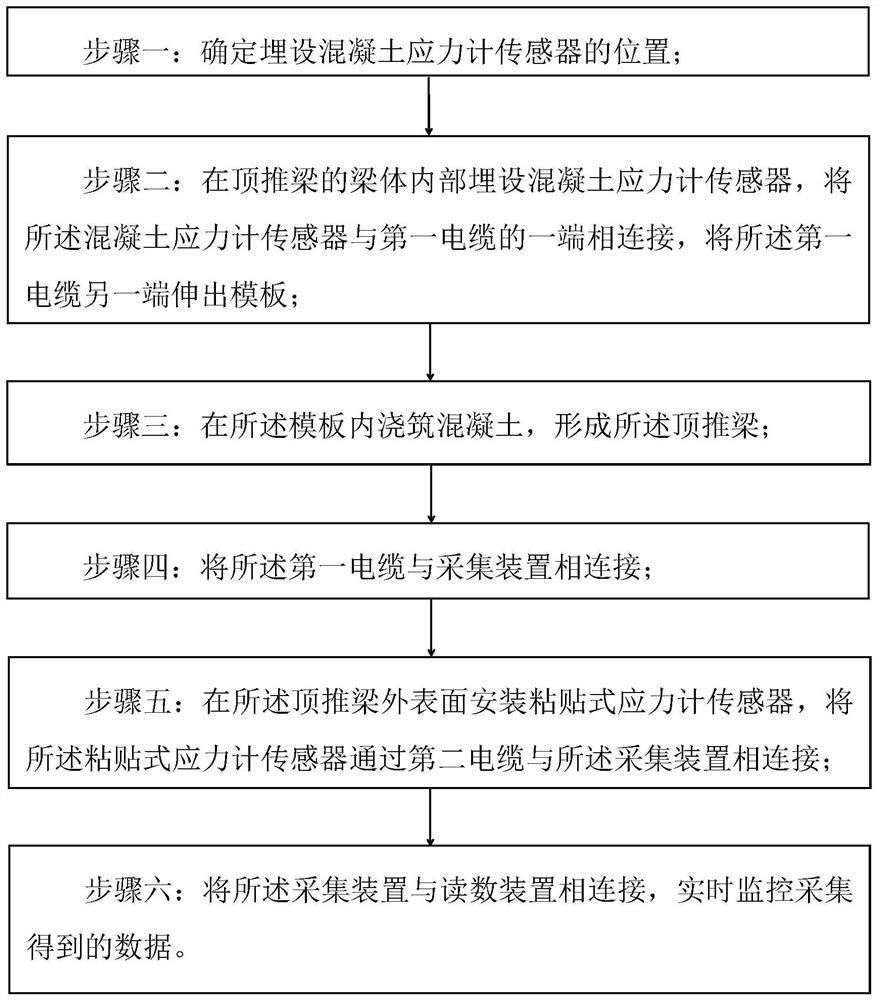

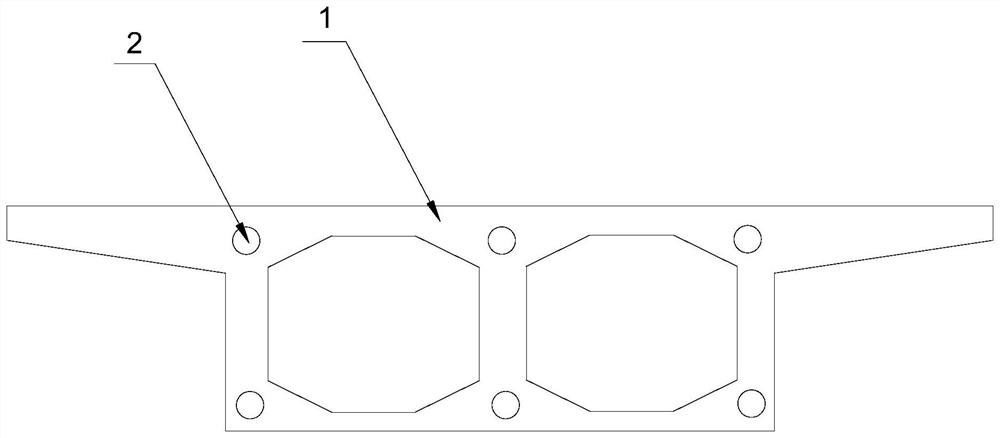

[0031] Such as Figure 1-Figure 2 As shown, a construction method for monitoring and controlling a push beam comprises the following steps:

[0032] Step 1: Use the beam grid method to perform simulation calculations to establish a spatial calculation model, simulate the entire process from the start of pushing to the completion of the bridge, and determine the position where the concrete stress gauge sensor 2 needs to be embedded in the pushing beam 1; in this embodiment, including A plurality of sections selected at intervals in the length direction of the push beam 1, and 6 concrete stress gauge sensors 2 are arranged on each section;

[0033] Step 2: Embedding a concrete stress gauge sensor 2 inside the beam body of the push beam 1, connecting the concrete stress gauge sensor 2 with one end of the first cable, and extending the other end of the first cable out of the template; The concrete stress gauge sensor 2 includes a back plate, an induction plate, a vibrating wire, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com