Equipment power supply reliability detection device and detection method thereof

A technology of power supply detection and detection device is applied in the field of reliability detection device of equipment power supply, which can solve the problems of inability to operate automatically, inability to test the power supply of the device under test, and increase the possibility of wrong judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

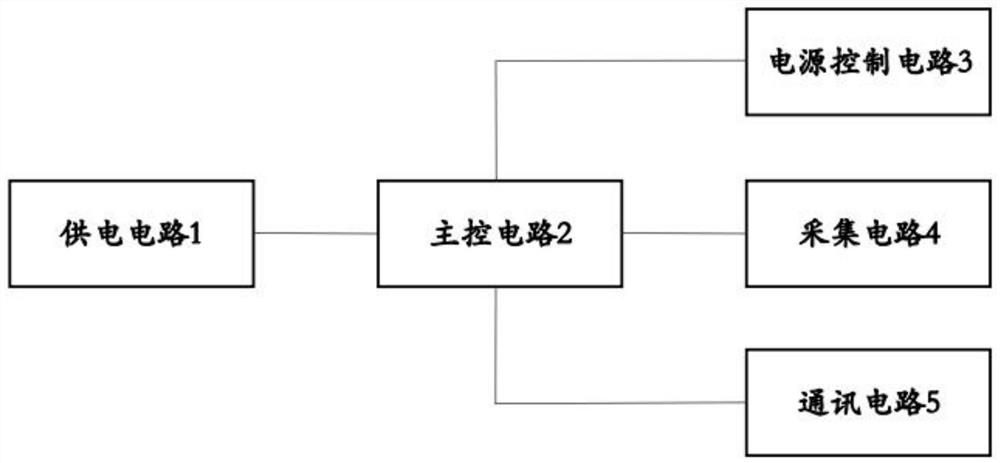

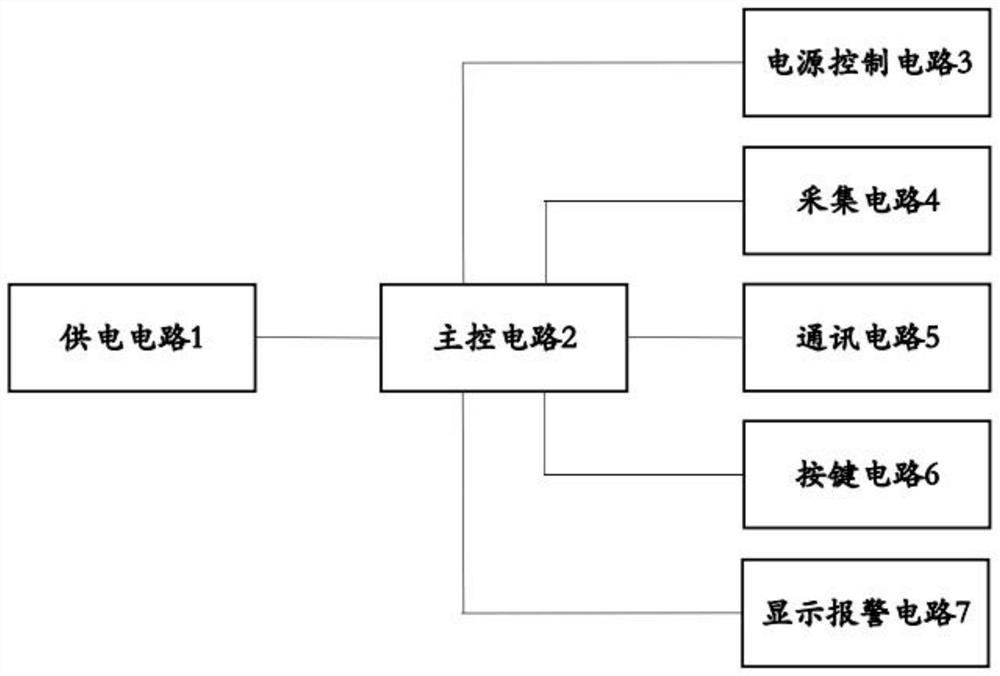

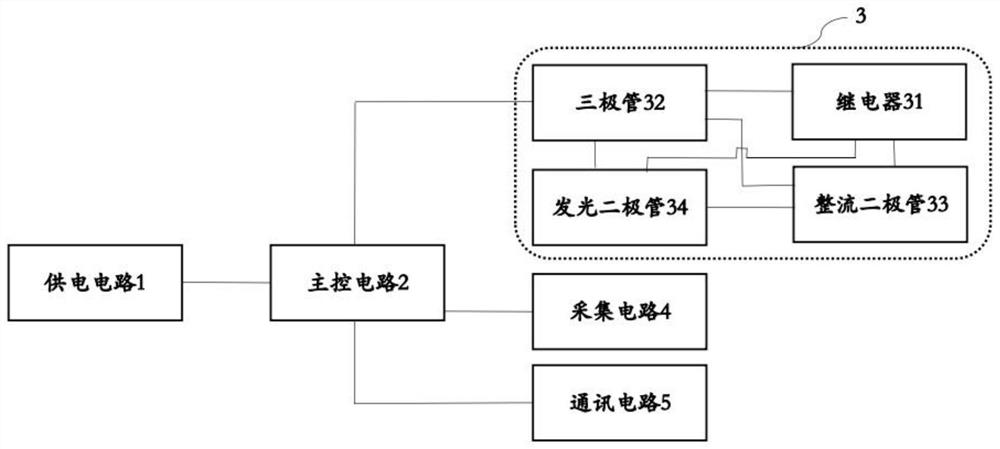

[0073] Embodiment one, as figure 1 As shown, a device power supply reliability detection device includes a power supply circuit 1, a main control circuit 2, a power control circuit 3, an acquisition circuit 4 and a communication circuit 5;

[0074] The power supply circuit 1 is used to supply power to the main control circuit 2, and supply power to the power control circuit 3, the acquisition circuit 4 and the communication circuit 5 through the main control circuit 2;

[0075] The power control circuit 3 is used to control the power-on and power-off of the power supply of the device under test;

[0076] The collection circuit 4 is used to obtain the operating current of the power supply of the device under test;

[0077] The communication circuit 5 is used to provide a communication channel for data transmission between the main control circuit 2 and the power supply of the equipment under test, and receive the data frame sent by the power supply of the equipment under test;...

Embodiment 2

[0105] Embodiment two, such as Figure 9 As shown, a reliability detection method of equipment power supply is applied to the reliability detection device of equipment power supply in Embodiment 1, including the following steps:

[0106] S1: Get the power detection strategy, current detection strategy and communication detection strategy;

[0107] S2: Use the power control circuit to control the power-on and power-off of the power supply of the device under test, and obtain the power detection status parameter value of the power supply of the device under test, and judge whether the power detection status parameter value conforms to the power detection strategy , if yes, then execute S3, if not, then determine that the reliability of the power supply of the device under test is not up to standard;

[0108] S3: Use the acquisition circuit to obtain the working current of the power supply of the device under test, and judge whether the working current conforms to the current de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com