Tire rubber mixing production energy management system

A technology for energy production and management systems, applied in the energy industry, general control systems, control/regulation systems, etc., can solve the problems of energy management stagnation, lack of unified standards, lack of real-time and accuracy, etc., to ensure accuracy, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the rubber mixing production energy management system will be described in detail below in conjunction with the accompanying drawings. It is to be understood that the disclosed embodiments are merely examples of the ways in which certain aspects of the application may be practiced, and do not represent an exhaustive list of all the ways in which the invention may be practiced. Any specific structural and functional details disclosed herein are not to be interpreted as limiting.

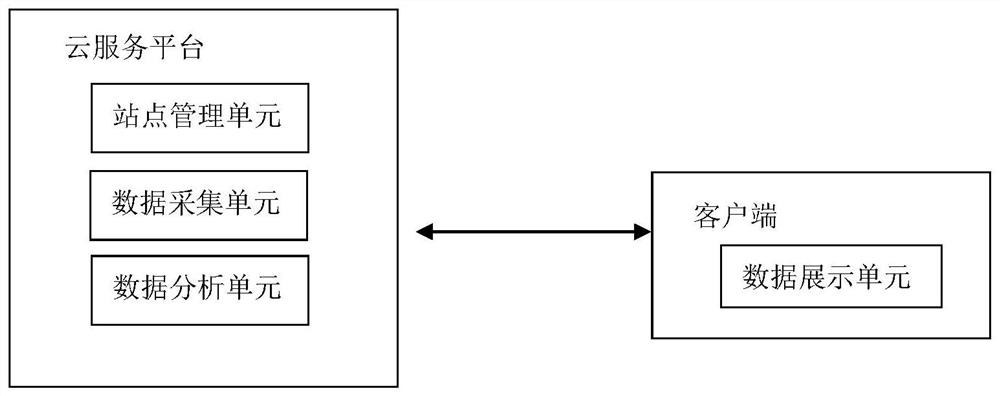

[0021] refer to figure 1 An energy management system for tire rubber production is shown, which includes a cloud service platform and a client, one or more clients access the cloud service platform, and data interaction is performed between the cloud service platform and the client.

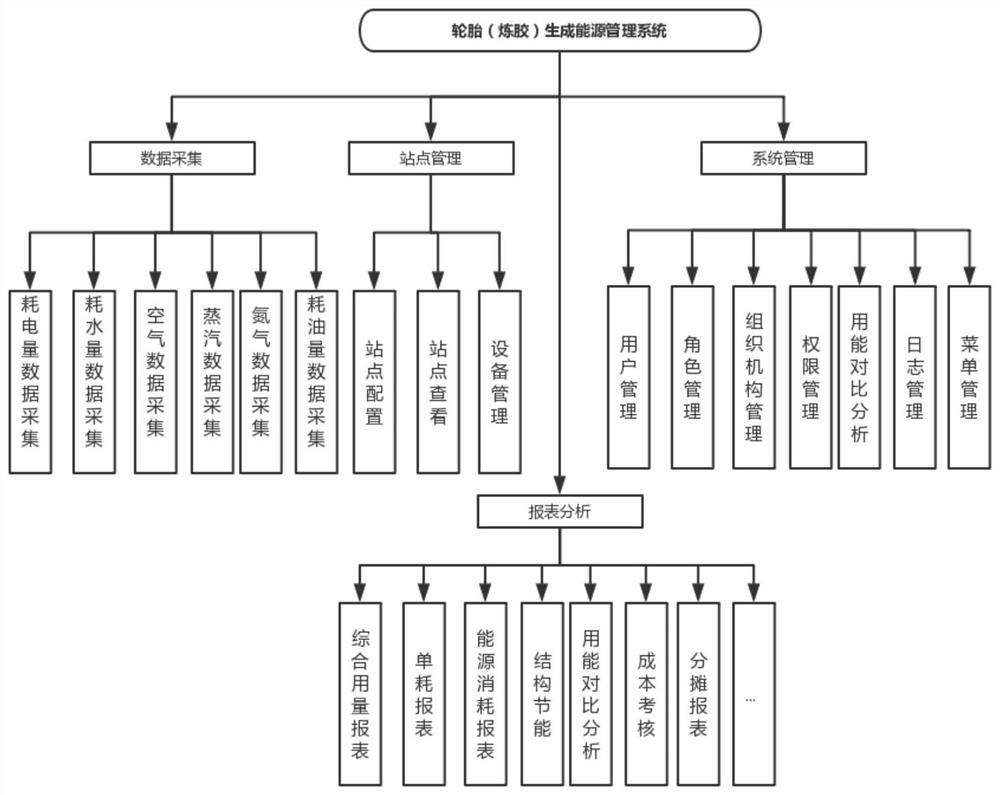

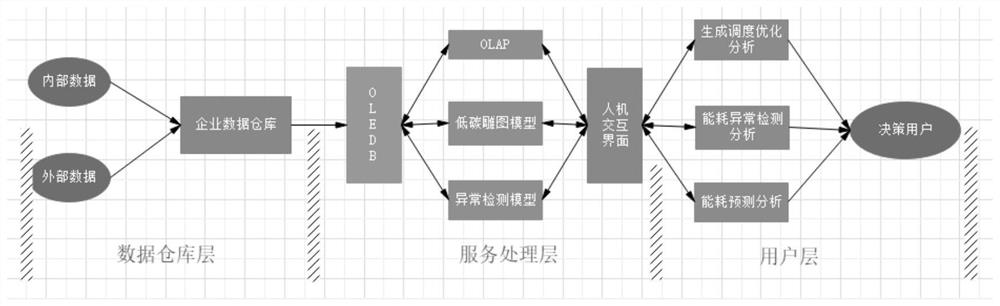

[0022] combine figure 2 , the cloud service platform includes a site management unit, a data acquisition unit, and a data analysis unit, and the client includes a data display unit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com