Solid catalyst for synthesizing dihydroxyacetone by glycerol oxidation

A technology for synthesizing dihydroxyacetone and solid catalysts, which is applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, and preparation of organic compounds, which can solve the problems of active metal loss, catalyst deactivation, Stability needs to be improved to achieve high selectivity, high catalytic activity and selectivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 0.2g of bismuth nitrate, 2g of chitosan and 5g of melamine through mechanical ball milling, the rotating speed of the mechanical ball milling is 30HZ, and the ball milling time is 10min; Calcined at high temperature in the atmosphere for 2 hours; after the calcination, take 1 g of the calcined product and disperse it in 50 mL of deionized water, add 3.98 mL of chloroplatinic acid solution (4.89 mg / mL), stir at room temperature for about 2 hours, then add 0.0228 g of sodium borohydride solution (0.3mol / L), and then stirred for 5h, centrifuged, washed with deionized water, and vacuum-dried to obtain a solid catalyst Pt / BiNC.

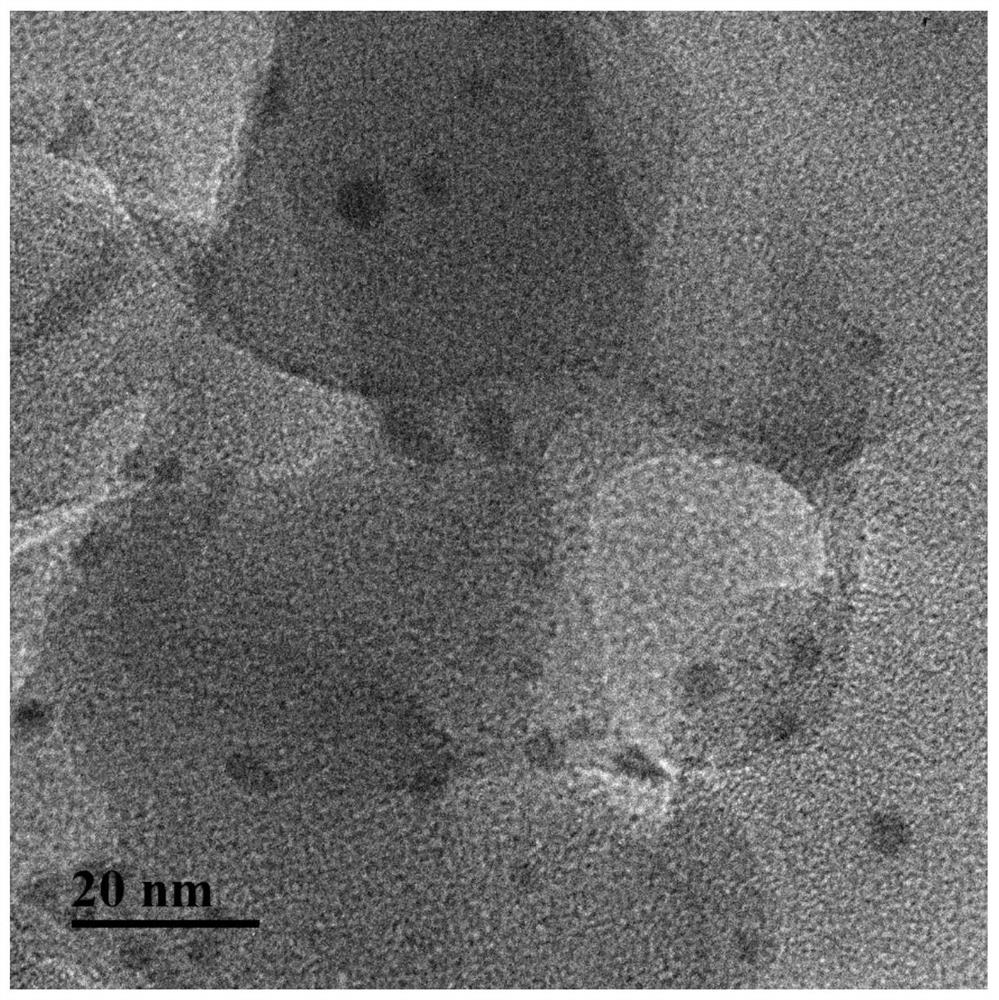

[0035] The photo of the solid catalyst Pt / BiNC prepared in this embodiment is as follows figure 1 As shown, it is a black solid powder. The solid catalyst Pt / BiNC prepared in this example was characterized by TEM, figure 2 Transmission electron microscope (TEM) image of the catalyst Pt / BiNC prepared for this example. Depend on figure 2 It ...

Embodiment 2

[0037] Mix 0.2g of bismuth nitrate, 2g of chitosan and 5g of melamine through mechanical ball milling, the rotating speed of the mechanical ball milling is 30HZ, and the ball milling time is 10min; Calcined at high temperature in the atmosphere for 2 hours; after the calcination, disperse 1 g of the calcined product in 50 mL of deionized water, add 3.98 mL of palladium chloride solution (4.89 mg / mL), stir at room temperature for about 2 hours, and then add 0.0228 g of sodium borohydride solution (0.3mol / L), and then stirred for 5h, centrifuged, washed with deionized water, and vacuum-dried to obtain a solid catalyst Pd / BiNC.

Embodiment 3

[0039] Mix 0.2g of bismuth nitrate, 2g of chitosan and 5g of melamine through mechanical ball milling, the rotating speed of the mechanical ball milling is 30HZ, and the ball milling time is 10min; Calcined at high temperature in the atmosphere for 2 hours; after the calcination, disperse 1 g of the calcined product in 50 mL of deionized water, add 2 mL of palladium chloride solution (4.89 mg / mL), stir at room temperature for about 2 hours, and then add 0.0114 g of sodium borohydride solution (0.3mol / L), then stirred for 5h, centrifuged, washed with deionized water, and vacuum-dried to obtain the solid catalyst Pt with low Pt loading. L / BiNC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com