Profile cutting device with adjustable cutting scheme

A technology of cutting scheme and cutting device, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems such as difficult to meet processing needs and single cutting, and achieve the effect of enriching cutting schemes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

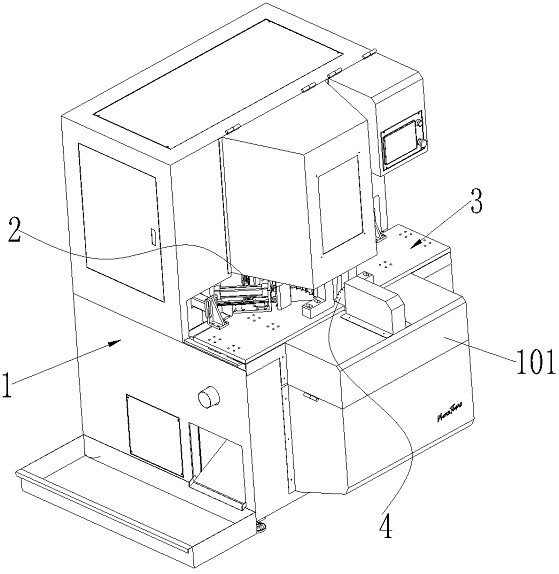

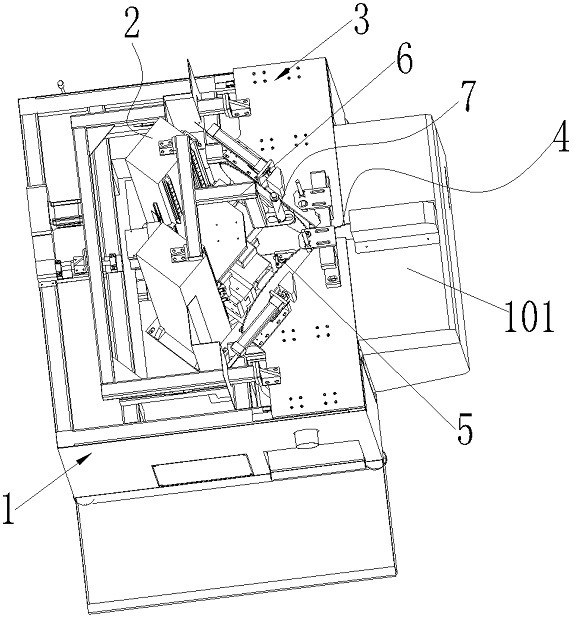

[0037] Such as Figures 1 to 9 As shown, a profile cutting device with an adjustable cutting scheme according to the present invention includes a frame 1, a lifting cutting module 2 and a translation cutting module 4; Translation table 3;

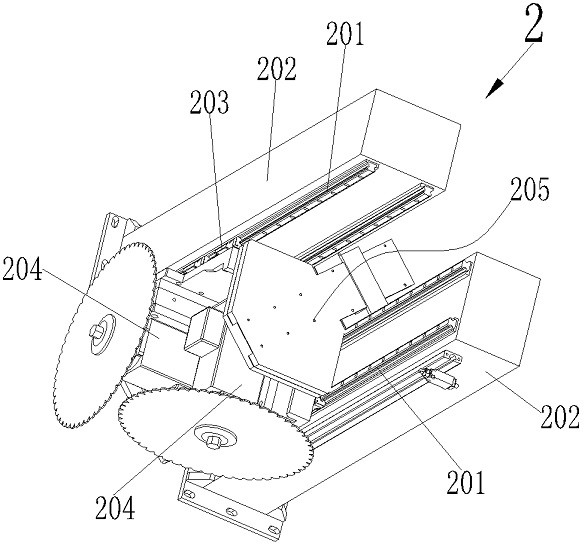

[0038] The lifting and cutting module 2 includes two cutting and lifting cutters 204 and a lifting mechanism for driving the two cutting and lifting and cutting machines 204 to perform synchronous lifting and lowering movements;

[0039] The translation cutting module 4 includes a translation cutting machine 401 and a translation driving mechanism for driving the translation cutting machine 401 to move forward and backward;

[0040] The cutterheads on the two cutting and lifting cutters 204 are lifting saw discs 204a; an included angle is formed between the two lifting saw discs 204a; the included angle is greater than 0° and less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com