Secondary welding cooling machine for air conditioner copper pipe

A secondary welding and cooling machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as insufficient technical index requirements, and achieve the effect of reasonable device structure design, uniform welding point, and expansion of welding range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below according to the drawings and embodiments.

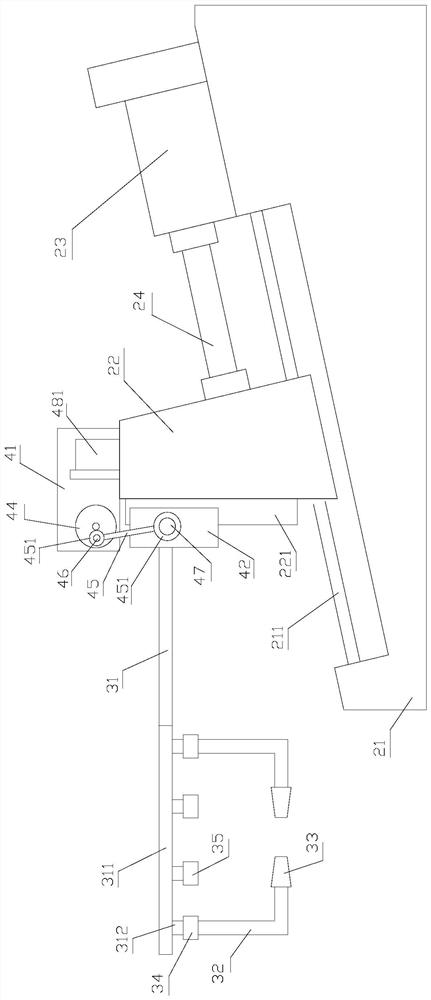

[0032] refer to Figure 1-Figure 8 According to the present invention, the secondary welding cooling machine for air-conditioning copper pipes includes: a conveying device, a first welding device, a second welding device, and a cooling device.

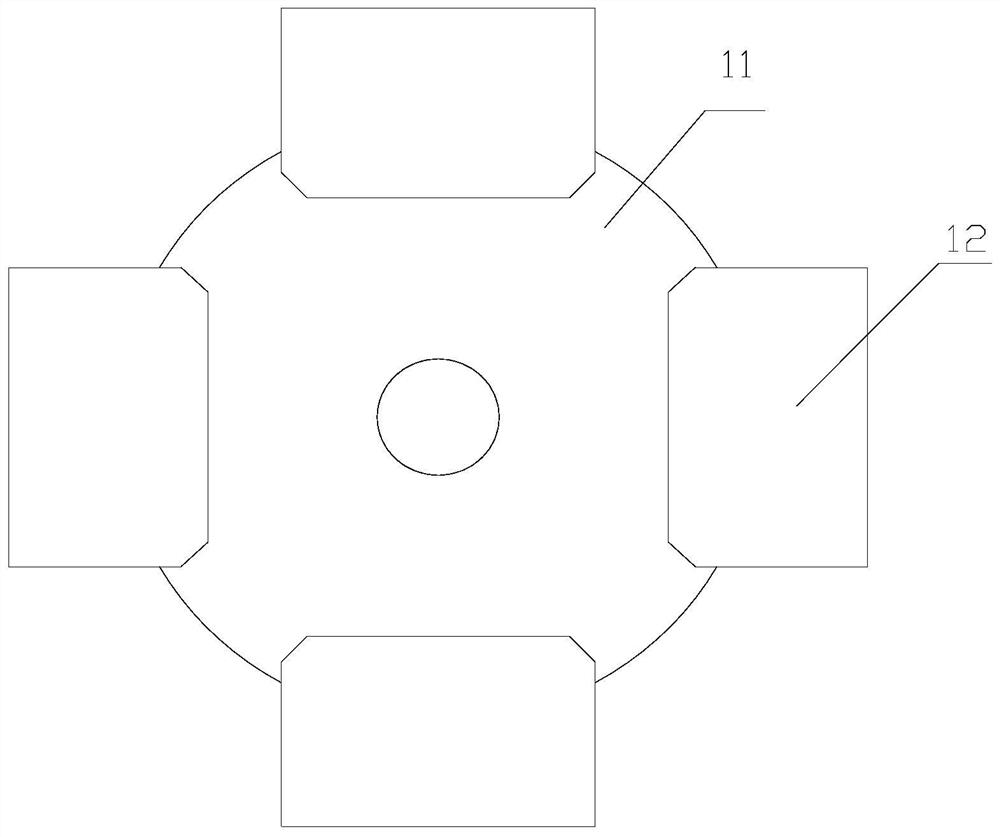

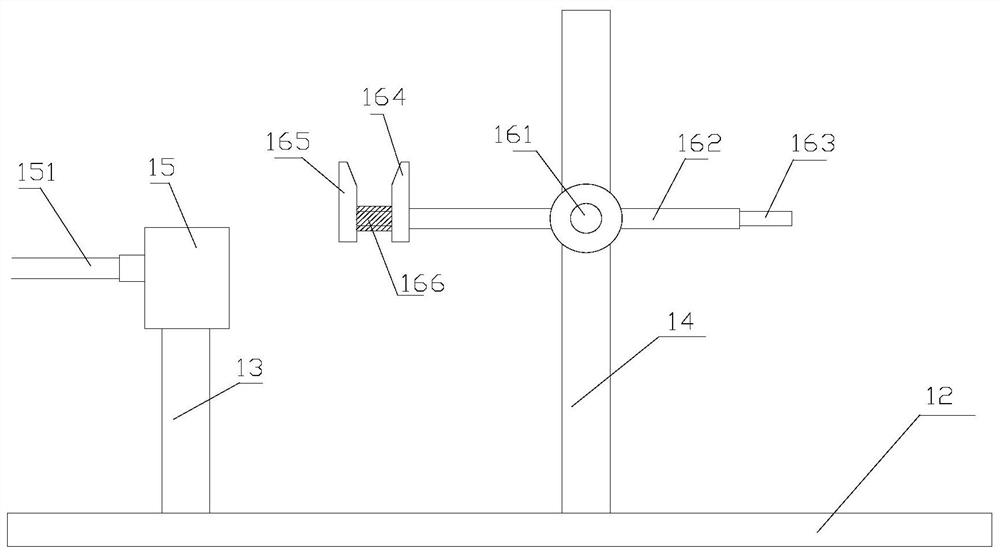

[0033] The conveying device includes a turntable 11 and a plurality of station seats 12, and a plurality of the above-mentioned station seats 12 are symmetrically fixed on the outside of the above-mentioned turntable 11 with respect to the center of the above-mentioned turntable 11, and the surface of the above-mentioned station seats 12 is fixed with a vertically arranged first support Rod 13 , second support rod 14 , the top of the first support rod 13 is provided with a bracket 15 , and the above second support rod 14 is provided with a clamping piece.

[0034] For the delivery device, the bracket 15 is a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com