Tin scraping soldering machine

A welding machine and tin scraping technology, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of welding quality operator influence, operator toxicity, uneven solder joints, etc., to achieve convenient operation, guarantee Welding quality and uniformity of solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

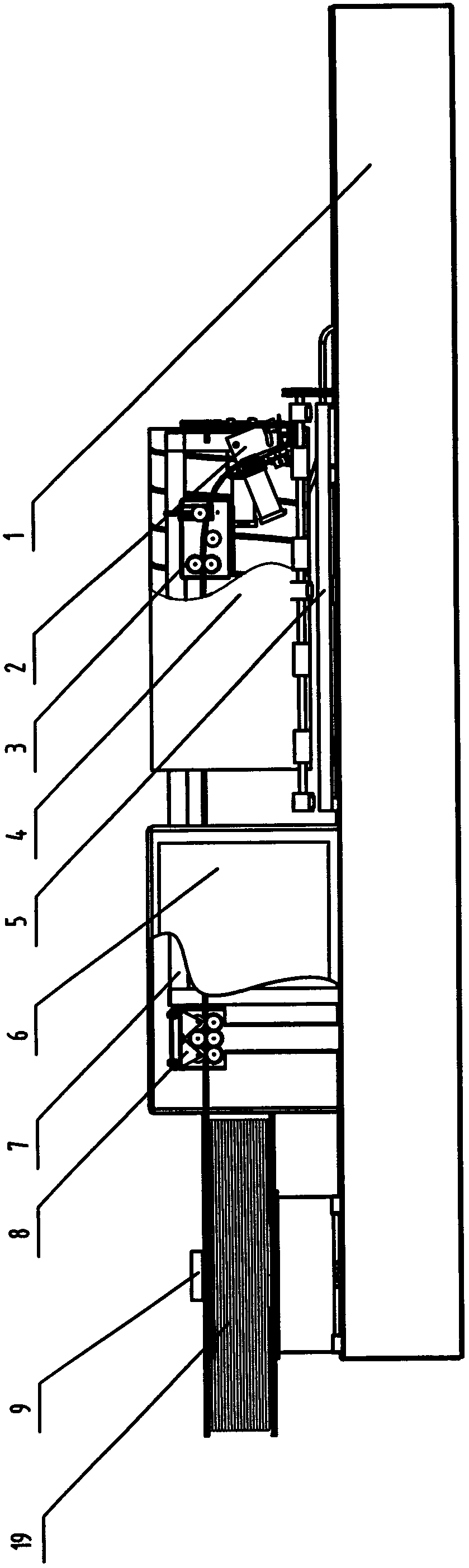

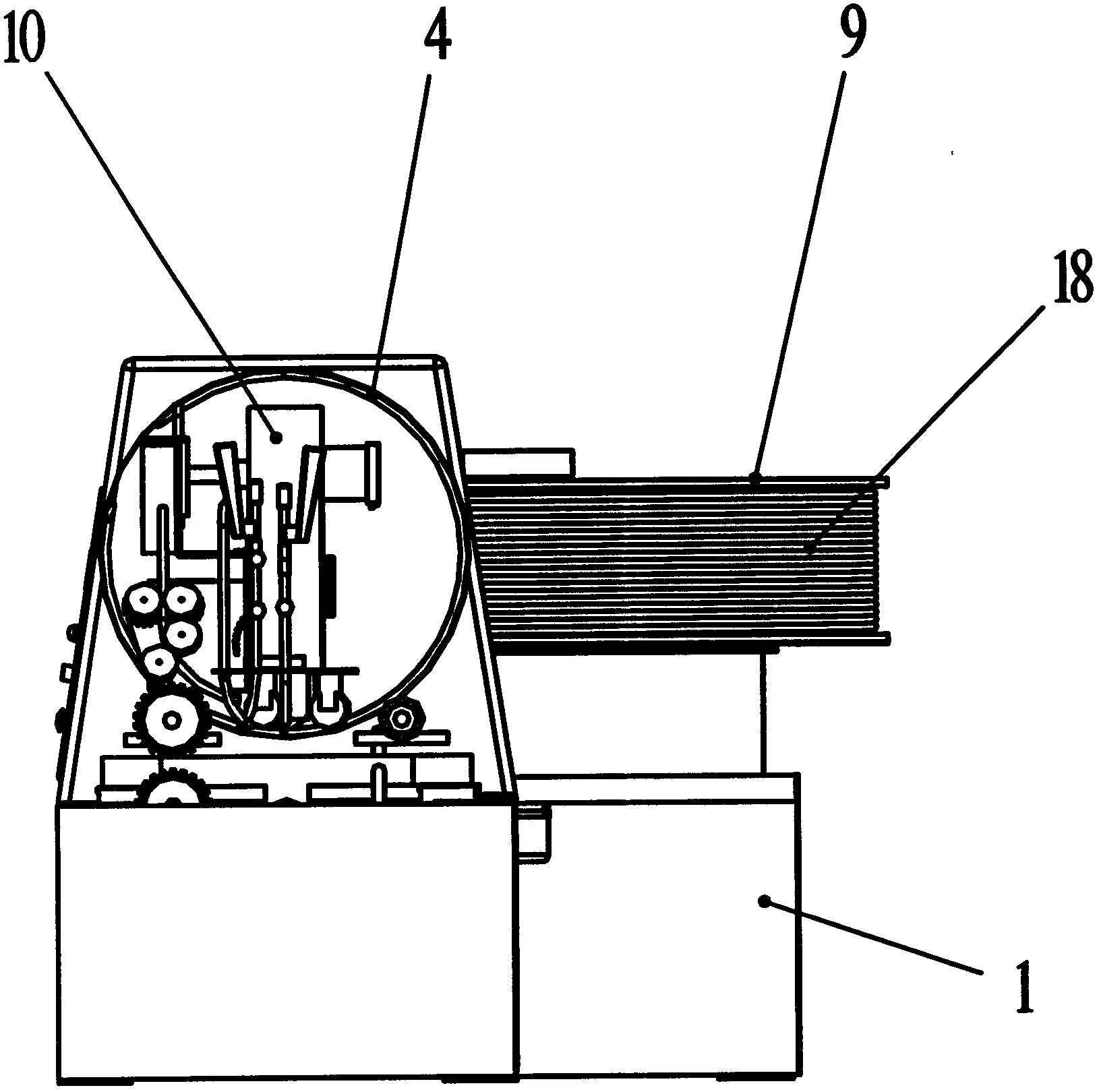

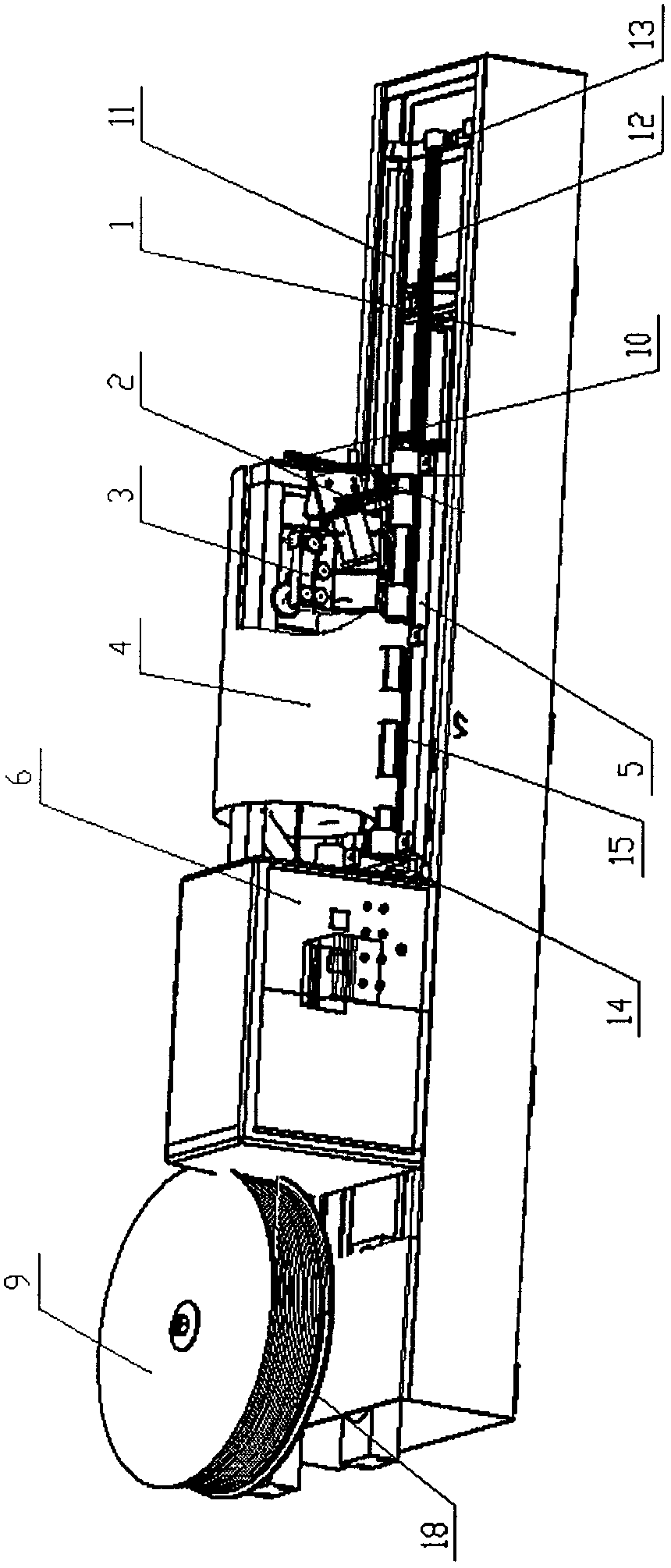

[0022] see Figure 1-Figure 7 , A tin scraping welding machine of the present invention is composed of a base bracket 1, a bending mechanism 2, a wire clamping mechanism 3, a cylinder 4, an execution unit 5, a hood 6, a forward arm 7, a linear traction mechanism 8, a copper tube The turntable bracket 9 and the vertical arm mechanism 10 are composed. The base bracket 1 plays a supporting role, the bending mechanism 2 changes the direction of the copper tube 18 , and the main pressing wheel 17 of the vertical arm mechanism 10 presses the copper tube 18 on the inner wall of the cylinder 4 . The execution unit 5 drives the cylinder body 4 to perform circular motion and linear motion at the same time, so that the movement trajectory of any point on the cylinder body 4 is synthesized into a spiral line. The welding wire is drawn out from the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com