Bar discharging device

A bar material and adjusting device technology, applied in metal processing and other directions, can solve the problems of no steering function, difficult maintenance, complex structure, etc., to achieve the effects of sensitive action, ensuring stability and safety, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

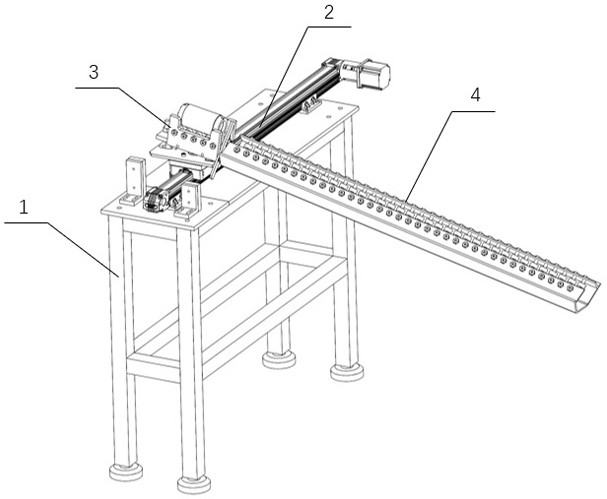

[0047] Such as figure 1 As shown, the embodiment of the present invention provides a bar blanking device, including a workbench 1 , a movement mechanism 2 , an angle adjustment mechanism 3 and a blanking mechanism 4 .

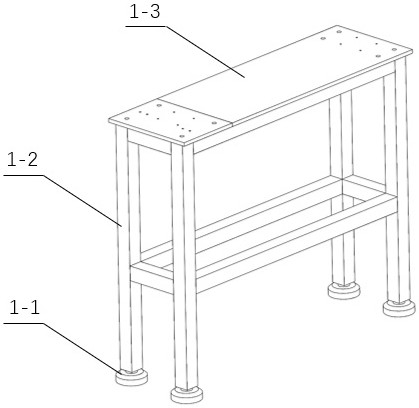

[0048] Such as figure 2As shown, the workbench 1 includes a foot 1-1, a table 1-3 and a table support 1-2 for supporting the table 1-3. One end of the ground foot 1-1 is horizontally placed on the ground, and the other end is connected with the table support 1-2 by bolts. Specifically, the foot 1-1 is an adjustment foot, which may be a plastic foot or a metal foot, and is used to ensure that the device table 1-3 is parallel to the ground. In this embodiment, the table support 1-2 is made by welding square pipes, and ordinary square pipes can be made into the table support 1-2, but it is not limited thereto, any pipe, rod, profile, etc. can be made Table support 1-2, any material can be used as the raw material of table support 1-2, and any fixing method can...

Embodiment 2

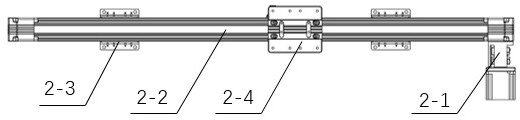

[0060] Such as Figure 8 , Figure 9 , Figure 10 As shown, the embodiment of the present invention provides a bar blanking device that can cooperate with the machine tool 5 and the truss manipulator 6 . When blanking, the angle adjustment mechanism 3 is located at the left end of the linear module 2-2, and the truss manipulator 6 picks the bar material processed by the machine tool 5 and places it in the workpiece groove 3-2, and the linear movement of the linear module 2-2 makes the workpiece Slot 3-2 moves to the right (based on attached Figure 7 And attached Figure 9 direction shown).

[0061] During the movement of the workpiece groove 3-2 to the right end, the rotating plate 3-5 touches the moving limit plate 3-9, and the rotating plate 3-5 drives the workpiece groove 3-2 to rotate clockwise around the rotating shaft 3-7 (based on the attached figure 1 directions shown, with Figure 8 And attached Figure 10 is the position after the rotation is completed). Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com