Limiting device for injection mold processing

A technology of limiting device and injection mold, which is applied in the direction of positioning device, workpiece clamping device, metal processing equipment, etc., can solve the problems that the injection mold cannot rely on the mold and the price of the injection mold is difficult to limit, and achieve a good clamping limit Good position effect, good limit effect, and good limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

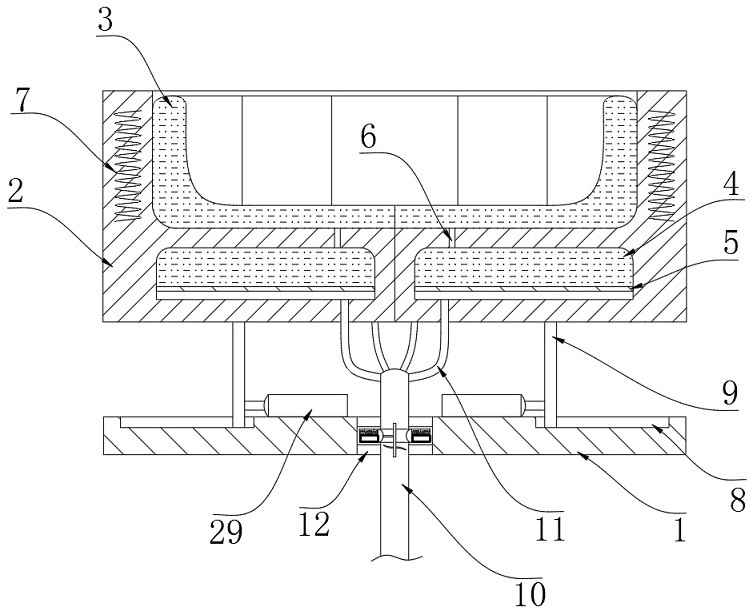

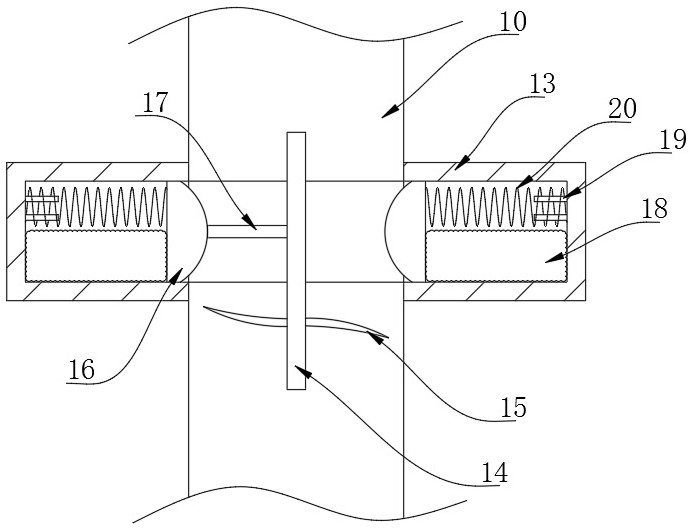

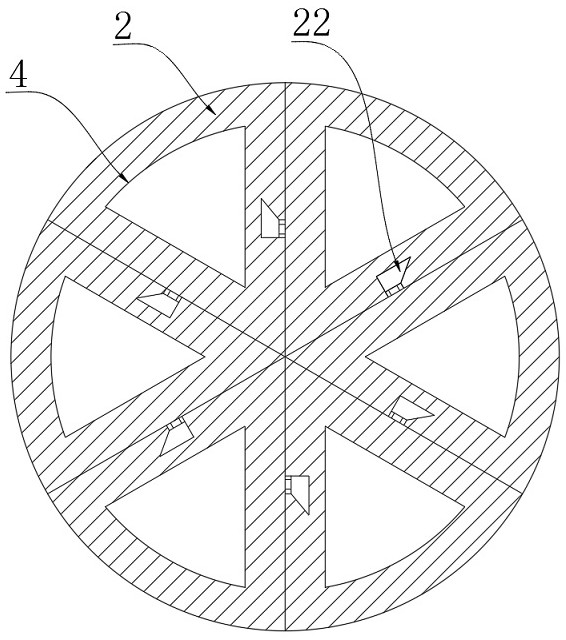

[0031] refer to Figure 1-6 , a limiting device for injection mold processing, comprising a base ring 1 arranged horizontally, the base ring 1 is slidably connected with a plurality of frame plates 2, the plurality of frame plates 2 offset to form a cylindrical structure, and the plurality of frame plates 2 form The cylindrical structure lacks the upper top surface; the inner wall of each frame plate 2 is sealed and glued with a plastic bag 3, the plastic bag 3 is a soft hollow bag body, and each frame plate 2 is provided with a liquid storage Cavity 4, inside the liquid storage chamber 4 is sealed and slidably connected with a slide plate 5, the area above the slide plate 5 in the liquid storage chamber 4 and the plastic bag 3 are filled with magnetorheological fluid, and the base ring 1 is provided with a number equal to that of the frame plate 2. Each chute 8 is provided along the radial direction of the base ring 1, and a connecting rod 9 is slidably connected in each chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com