Ignition system for afterburner

A technology of afterburner and ignition system, which is applied to gas turbine devices, jet propulsion devices, machines/engines, etc., can solve the problems of complex oil circuit system and insufficient engine thrust-to-weight ratio, etc., and achieve simple oil circuit system and ignition system. The effect of reducing the technical and economic indicators of the engine and the low cost of the ignition device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

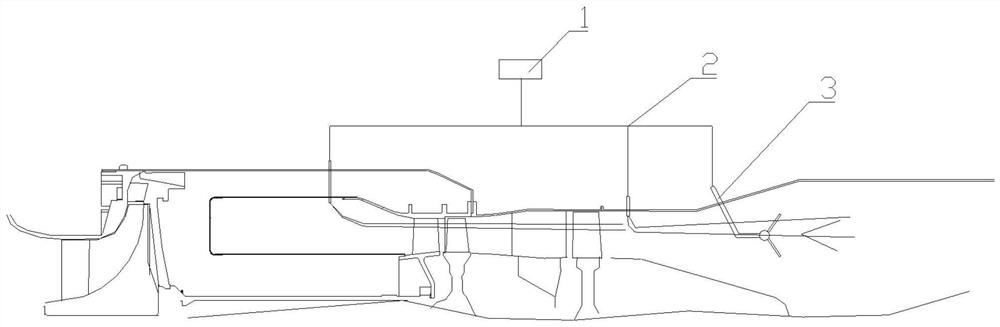

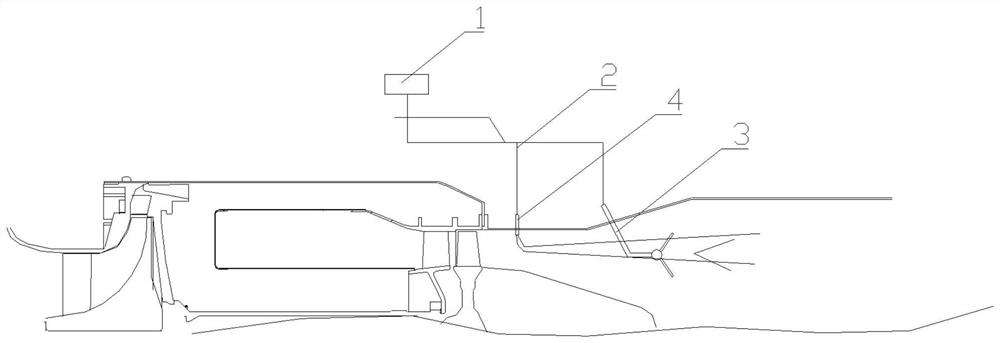

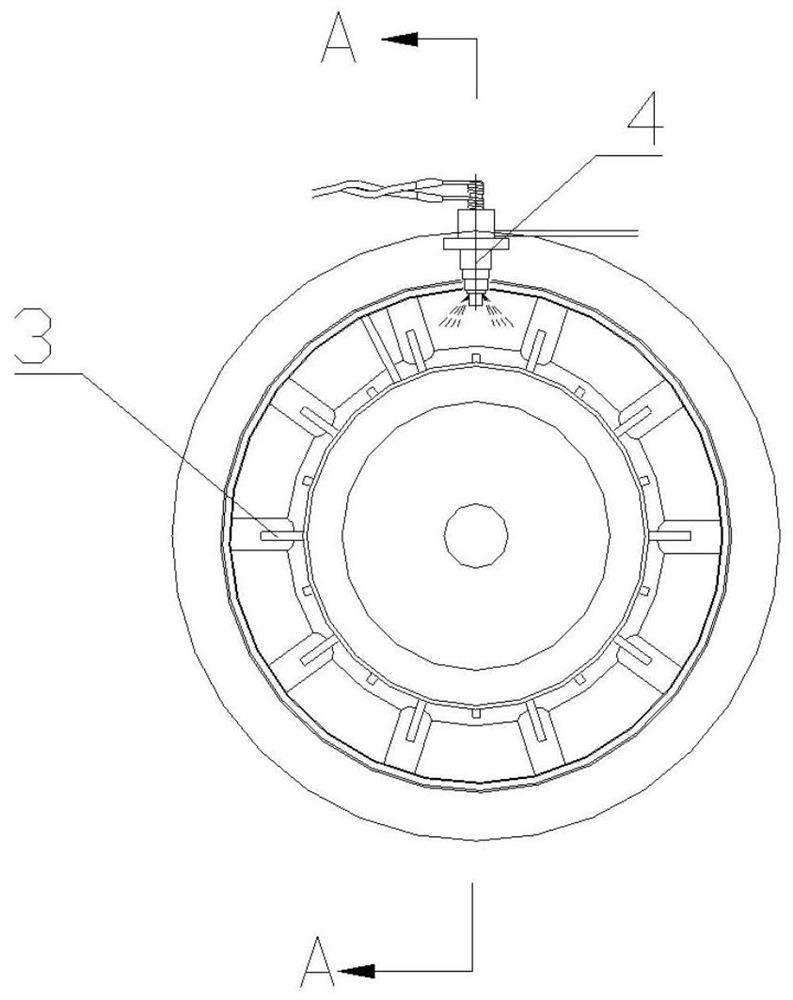

[0023] Such as Figure 2-6 As shown, an afterburner ignition system includes an ignition oil circuit system, the ignition oil circuit system includes an oil pump 1, and the oil pump 1 is respectively connected to an ignition device 4 and an afterburner fuel main pipe 3 through a pipeline 2, and the ignition device 4 includes a shell body 43, and a glow plug 42 is installed inside the housing 43, a cable 41 is arranged above the glow plug 42, and a booster ignition oil pipe 44 is arranged on the housing 43, and the booster ignition oil tube 44 is connected to the pipeline 2, and the glow plug The annular seam between 42 and the inner wall of the housing 43 forms an oil channel 45 , and the oil channel 45 communicates with the afterburner oil pipe 44 .

[0024] Working principle: Pipeline 2 is sealed and connected with oil pump 1, ignition device 4 and afterburner fuel main pipe 3 through mechanical structure, ignition device 4 is fixed on the front end of afterburner diffuser t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap