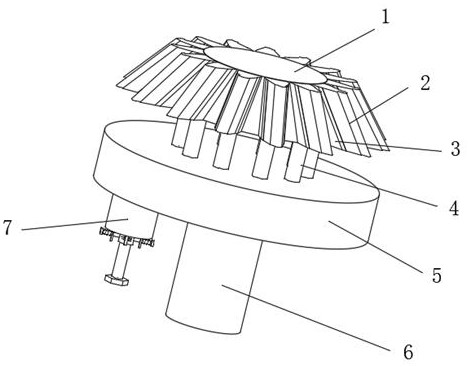

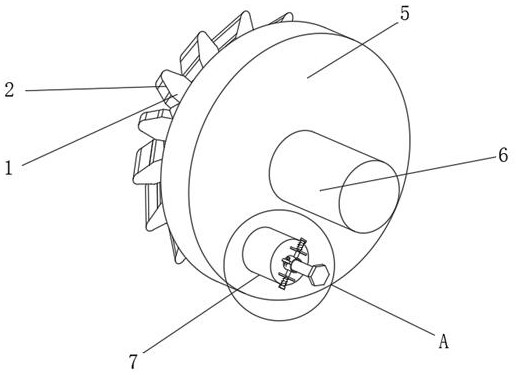

Novel noise-reduction type bevel gear and manufacturing method thereof

A bevel gear and noise reduction technology, which is applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve problems such as meshing noise, poor fit of gear surfaces, and gear knocking noise, etc., to achieve Reduce the gap, good use effect, reduce the effect of collision friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

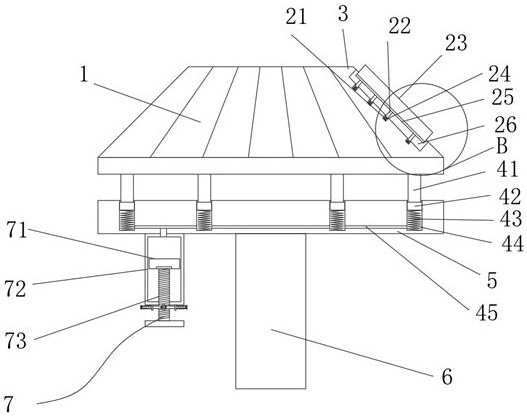

[0032] As an embodiment of the present invention, the tooth assembly 3 includes a return spring 21, a positioning rod 22, an arc-shaped rack 23, a positioning hole 24, a shock-absorbing cotton 25, and a tooth socket 26, and the tooth socket 26 is opened on the tooth socket. Inside the frame 2, a positioning hole 24 is provided in the bottom groove wall of the tooth groove 26, and a positioning rod 22 is inserted in the positioning hole 24, and the bottom end of the positioning rod 22 is fixedly connected to the wall of the positioning hole 24. Back-moving spring 21 is arranged, and arc-shaped tooth bar 23 is installed on the top of positioning bar 22, and the bottom side of arc-shaped tooth bar 23 is pasted with damping cotton 25.

[0033] As an embodiment of the present invention, the limit assembly 4 includes a limit rod 41, a rubber ring 42, an expansion spring 43, a rod hole 44 and a communication hole 45, and the inside of the gear seat 5 is provided with a plurality of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com