A Boiler with Heating Alternately Started

A boiler and electric heater technology, which is applied in the field of steam generating equipment, can solve the problems affecting the efficiency of descale heating of the coil, weaken the vibration performance of the coil, and decrease the heating power, so as to realize the heating efficiency, descaling operation, increase Elastic vibration effect, effect of promoting flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

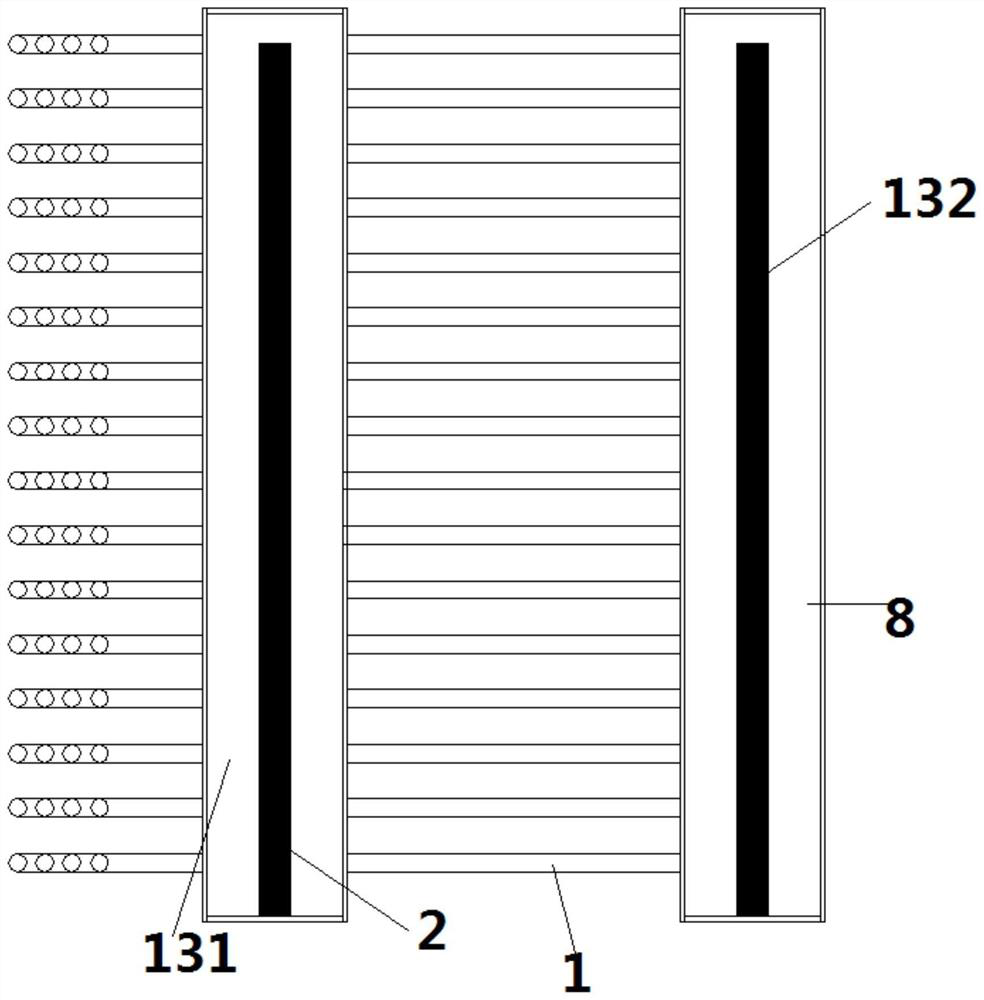

[0027] A boiler. The boiler includes an electric heating device 10 and a steam drum 11 . The electric heating device 10 is arranged in the steam drum 11 . The steam drum 11 includes a water inlet pipe 5 and a steam outlet 6 . The steam outlet 6 is arranged on the upper part of the steam drum.

[0028] Preferably, the steam drum is a cylindrical structure.

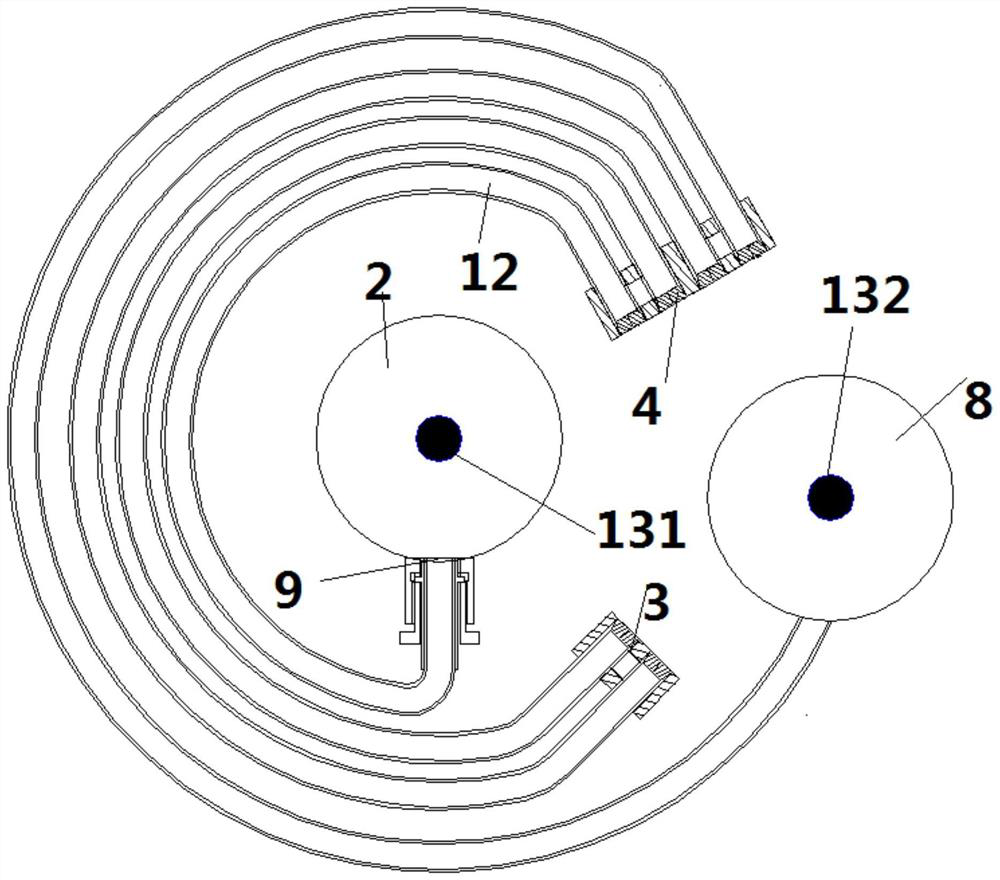

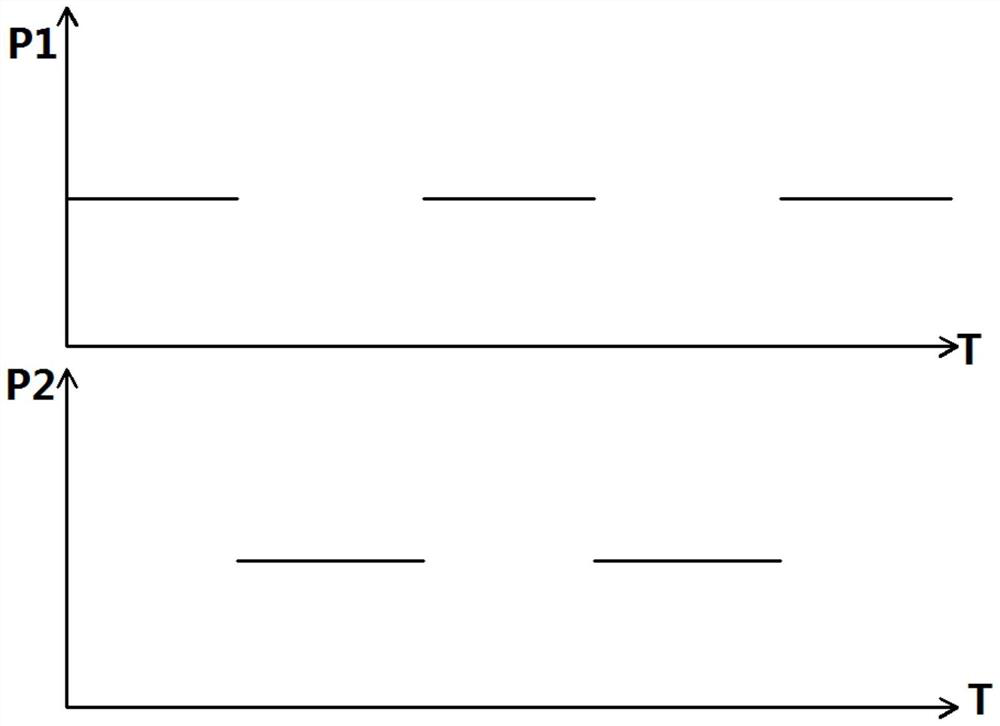

[0029] figure 1 A top view of the electric heating device 10 is shown, as figure 1 As shown, the electric heating device 10 includes a first tube box 2, a second tube box 8 and a coil 1, and the coil 1 communicates with the first tube box 2 and the second tube box 8, and the fluid in the first tube box 2 and the second tube box 8 and the coil 1 are in a closed cycle, and electric heaters 131 and 132 are arranged in the electric heating device 10, and the electric heater 13 is used to heat the inner fluid of the electric heating device 10, and then passes through The heated fluid heats the water in the drum.

[0030] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com