Groove type photo-thermal power generation tracking light source device based on photosensitive sensors

A photosensitive sensor and photothermal power generation technology, applied in solar thermal power generation, solar thermal energy, solar collectors, etc., can solve the problems of poor versatility and complicated initialization settings, so as to save electric energy, simplify installation and setting work, and realize generalization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

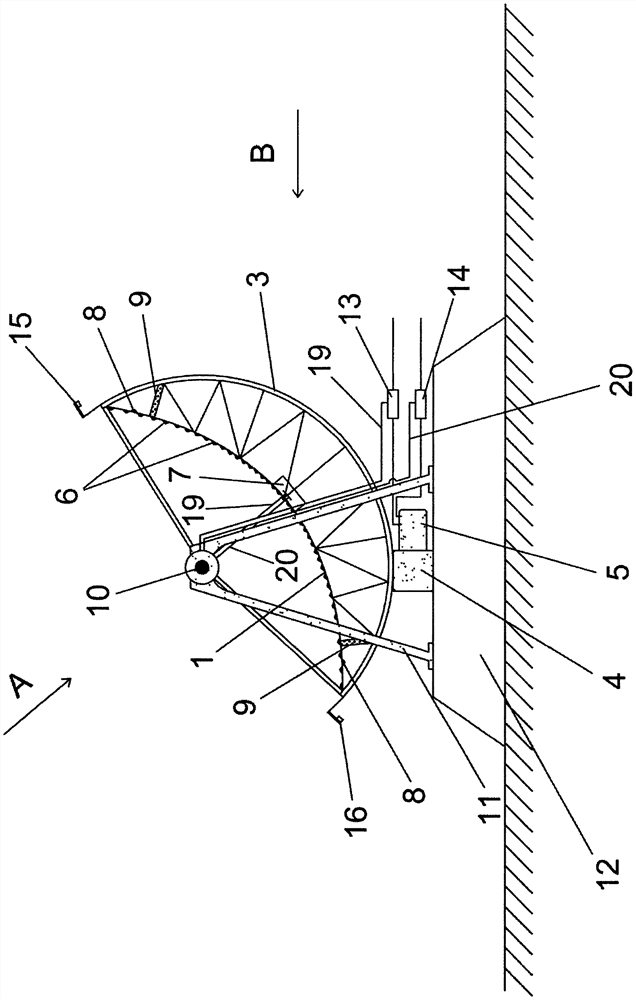

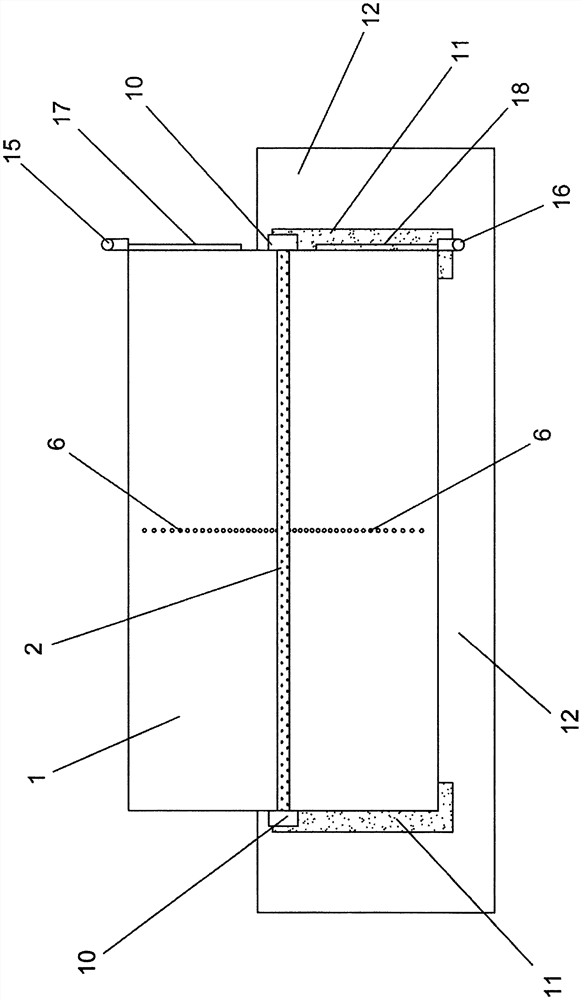

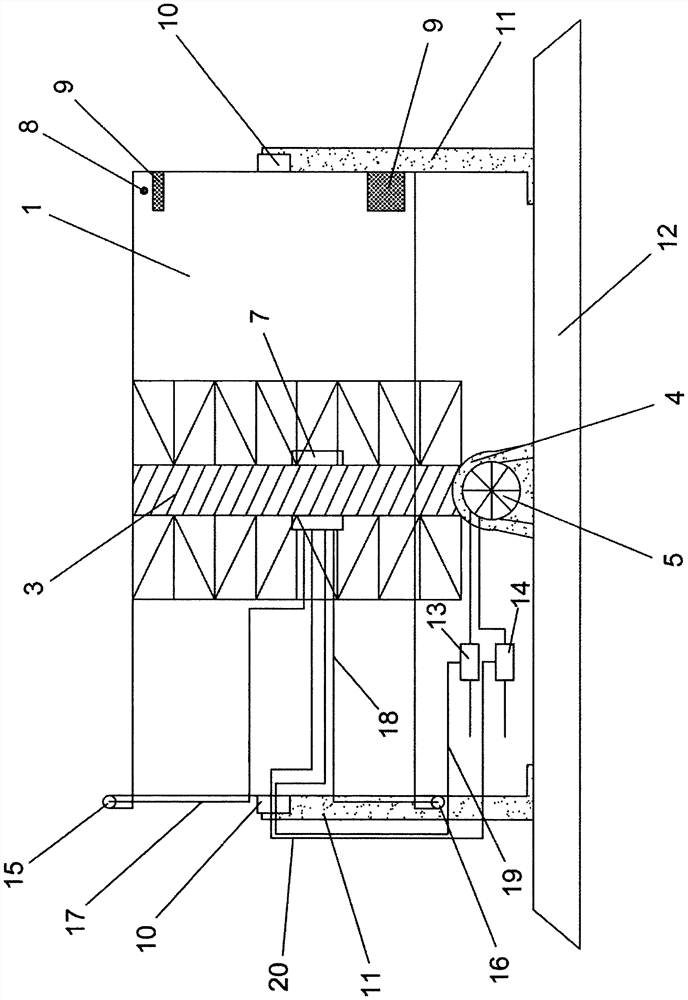

[0016] The trough-type photothermal power generation tracking light source device based on photosensitive sensors includes a trough-type parabolic reflector 1, a heat collecting tube 2, and the reflector 1 is fixed on the arc support 3. There is a gear bar on the side of the arc support 3 away from the center of the circle, and through These gear bars are meshed with the gears on the speed reducer 4, and the speed reducer 4 is connected with the bidirectional adjustment motor 5. A group of photosensitive sensors 6 are installed on the reflective mirror 1 facing the light source. The arrangement direction of the photosensitive sensors 6 and the extending direction of the heat collecting tube 2 are perpendicular to each other. Each photosensitive sensor 6 is connected to the controller 7 by a signal line, and each photosensitive sensor 6 is A data transmission interface on the controller 7 is occupied, and the position of the photosensitive sensor 6 on the mirror 1 corresponds to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com