Indexable motor gap automatic measuring device and measuring method

A measurement device and automatic measurement technology, which is applied in the field of precise detection of aerospace inertial devices, can solve the problems of large measurement errors, cumbersome measurement steps, repeated clamping, etc., and achieve the effects of improving production efficiency, shortening measurement time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the present invention in detail, and the features and advantages of the present invention will become more clear and definite along with these descriptions.

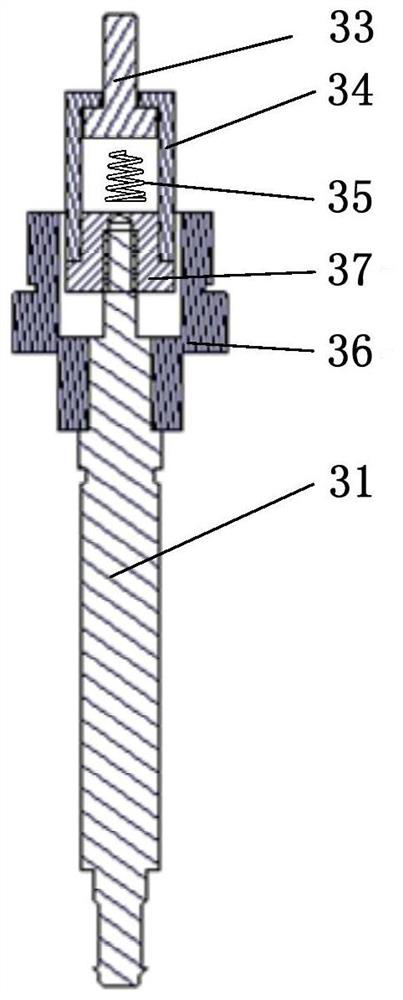

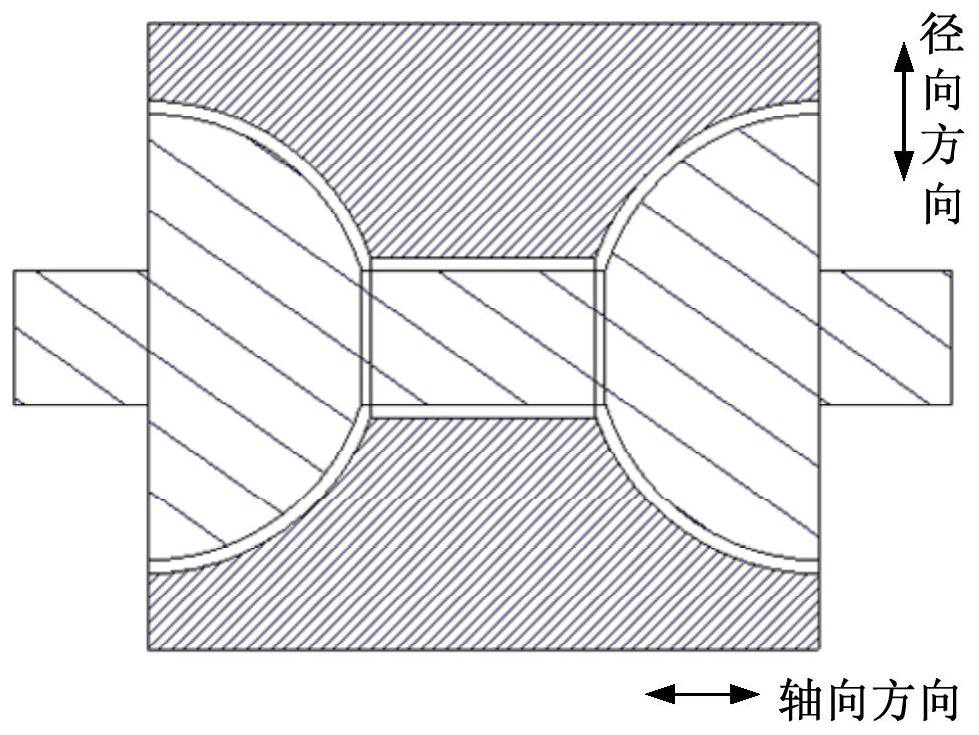

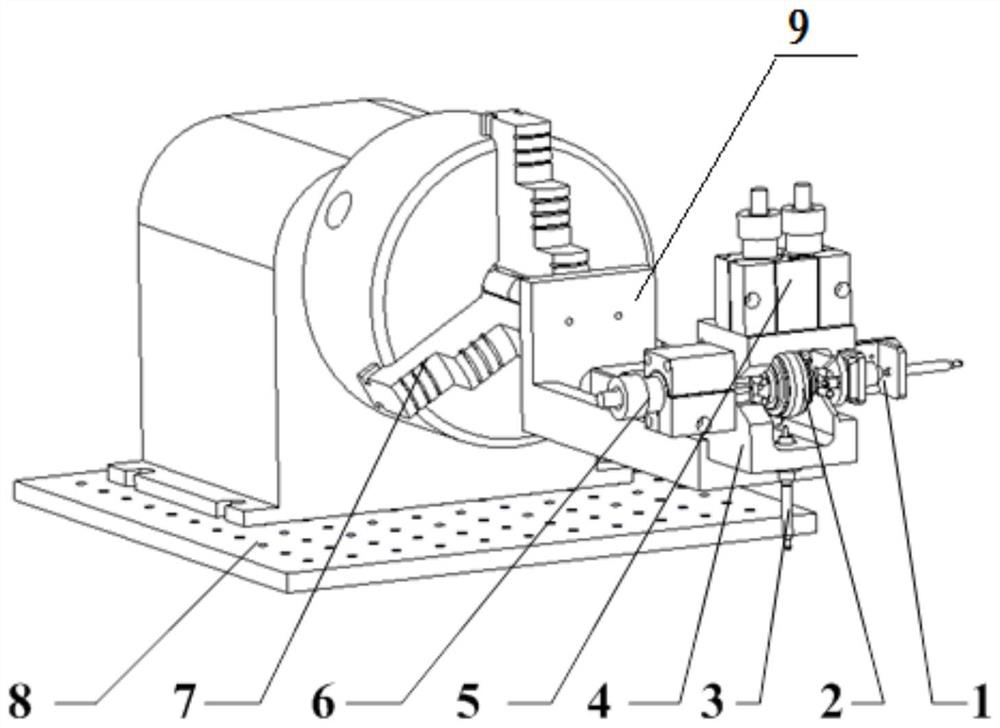

[0037] According to the first aspect of the present invention, such as figure 2 and image 3 As shown, an automatic gap measurement device for an indexable motor is provided. The measurement device includes an axial loading module 1, a radial loading module 3, a measuring tool 4, a radial measuring module 5, an axial measuring module 6, and Module 9 and attitude indexing module 7, wherein,

[0038] The measuring tool 4 is a shell structure, the motor 2 is fixed inside, and the axial loading module 1, the radial loading module 3, the radial measuring module 5 and the axial measuring module 6 are loaded on the shell;

[0039] The axial loading module 1 is fixed on the measuring tool 4 along the axial direction of the motor 2, and is used to apply an axial loading force to the motor 2;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com