Complex transmission chain predictive maintenance system and method based on industrial Internet of Things

An industrial Internet of Things and maintenance system technology, applied in the field of equipment predictive maintenance systems, can solve problems such as the complexity of fault signal types, complex signals, and complex mechanism models, and achieve the effect of solving multi-time scale data fusion and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection scope of the present invention are not limited thereto.

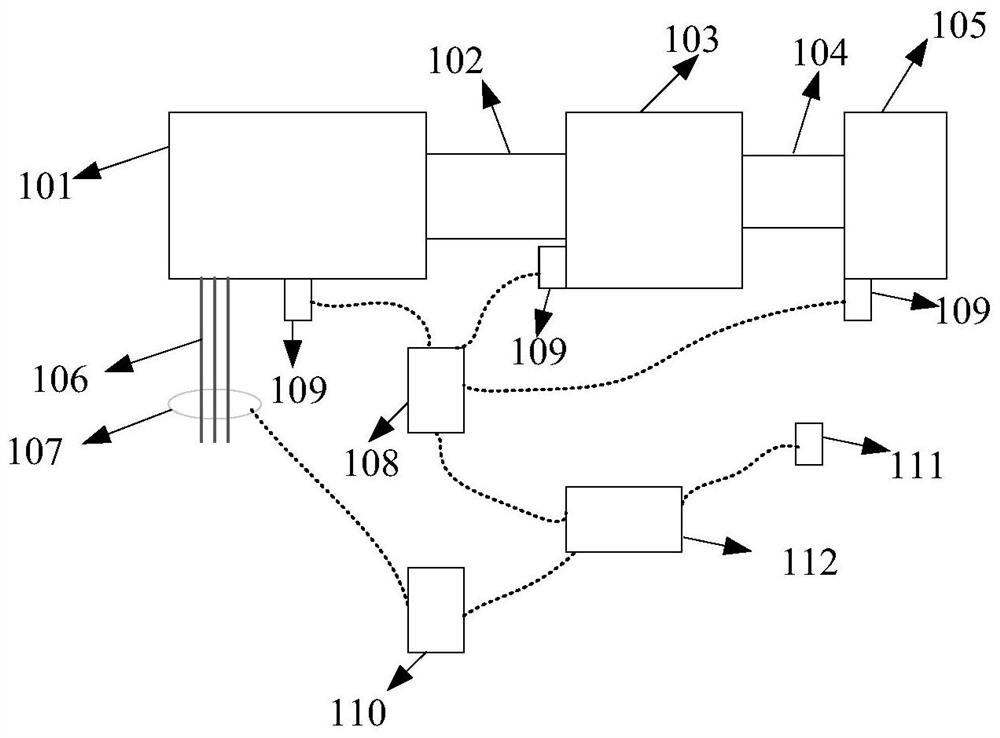

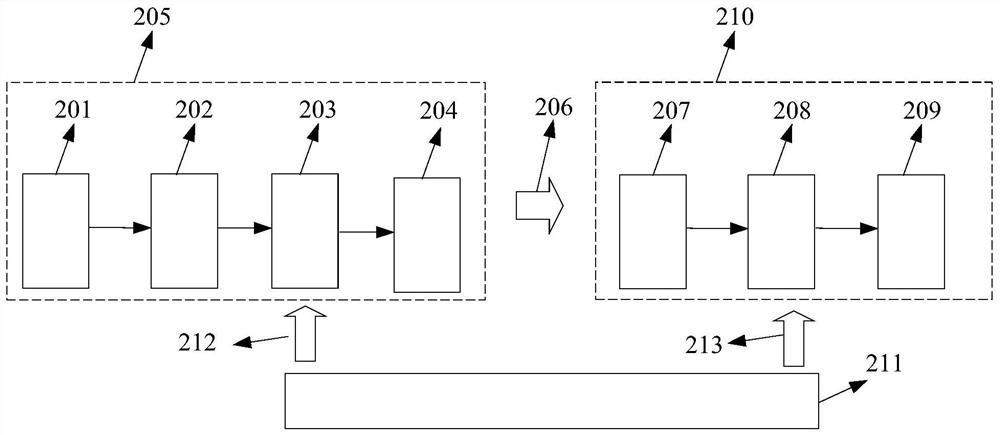

[0037] The present invention is a complex transmission chain predictive maintenance system based on the industrial internet of things, which includes two parts: hardware equipment and data link. Hardware equipment includes high-frequency sensor networks, high-frequency signal processing devices, and intelligent hardware. High-frequency sensor networks include temperature sensors, vibration sensors, displacement sensors, and current and voltage sensors; high-frequency signal processing devices include vibration signal acquisition and processing Devices, current and voltage signal acquisition and processing devices mainly realize data preprocessing; intelligent hardware mainly realizes local processing and transmission of data, which can be but not limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com