Steel bar machining method based on intelligent factory

A kind of steel bar processing and intelligent technology, applied in data processing applications, instruments, calculations, etc., can solve the problems of difficult control of processing quality and progress, high labor intensity, and low production efficiency, so as to reduce manual intervention, improve production efficiency, and ensure The effect of efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

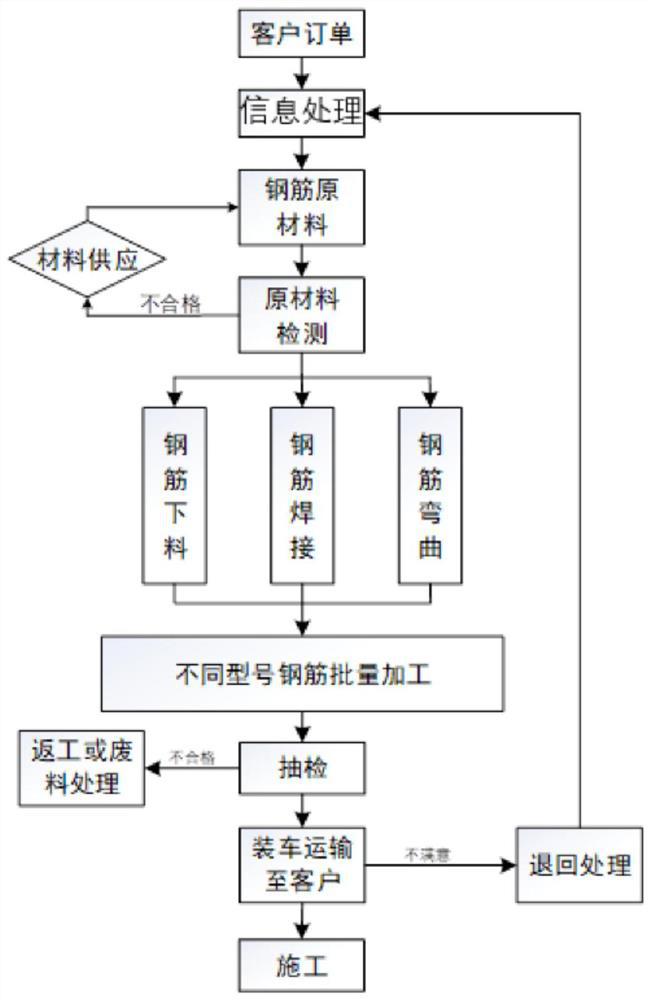

[0027] figure 1 The smart factory-based steel bar processing method shown in includes the following steps:

[0028] S1. Obtain user orders through the information management system, and form an optimal production process through data preprocessing;

[0029] S2. Communicate with the AGV trolley through the information management system to check whether the on-site steel bar raw materials are qualified;

[0030] S3. The information management system unloads the production lines of different machining devices according to the optimal production process formed by pretreatment;

[0031] S4. The controllers of the production lines of different machining devices perform pre-processing and batch processing of steel bars according to the received instructions;

[0032] S5. After the batch processing of each production line is completed, the AGV t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com