Locking device for ventilator

A technology for locking devices and ventilators, applied to pump devices, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve the problems of shortening the service life of components, being unable to measure, and being expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

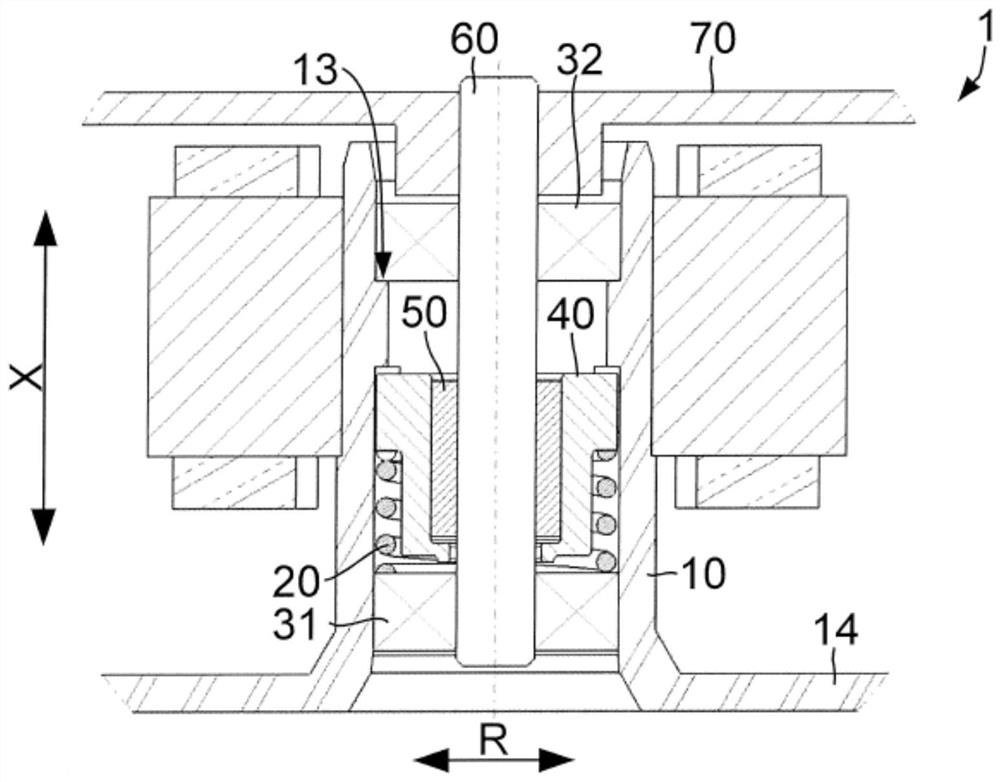

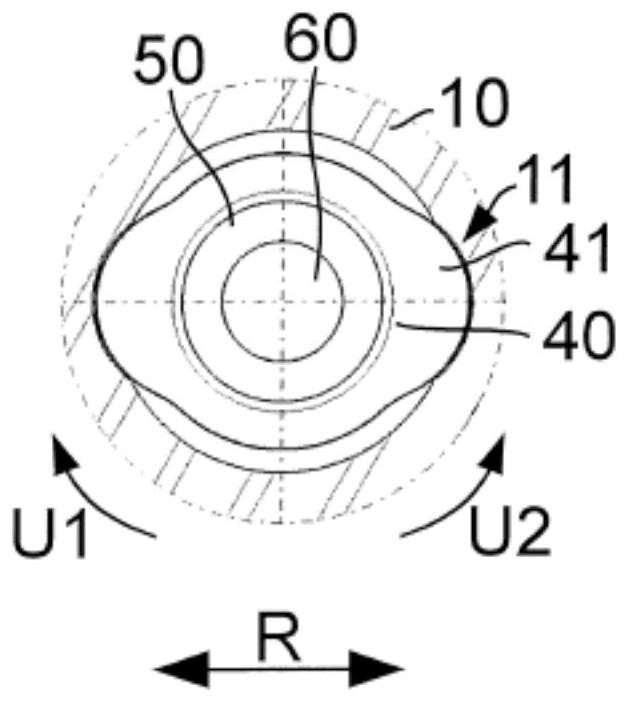

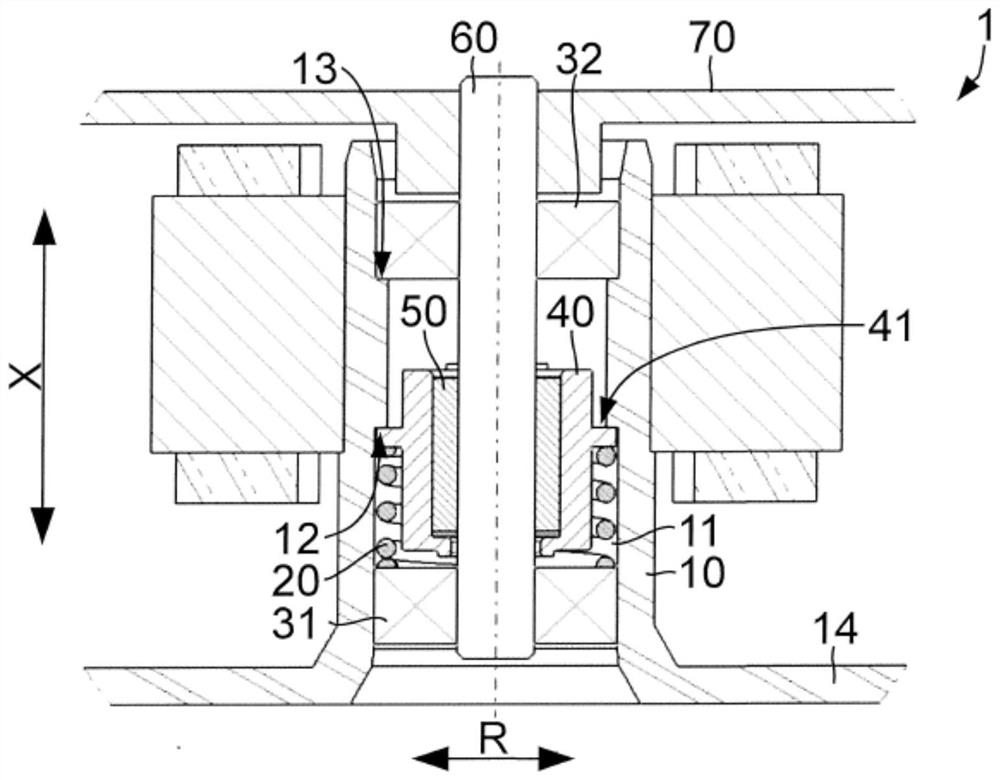

[0030] The accompanying drawings are illustrative schematic diagrams. In the figures, the same reference signs refer to the same functional and / or structural features.

[0031] exist figure 1 , image 3 and Figure 4 In the shown locking device 1 for a ventilator (not shown), the rotor shaft 60 extends through the support tube 10 along the axis of rotation (shown in dotted lines). The rotor shaft 60 is mounted relative to the support tube 10 by means of a bearing arrangement consisting of a first bearing 31 and a second bearing 32 . The free-running sleeve 50 is slipped over a section of the rotor shaft 60 and is connected to the rotor shaft in a rotationally fixed manner, for example in a clamping manner. On its underside, the support tube 10 adjoins a flange 14 by means of which the locking device 1 can be fastened, for example, to a base plate or a housing. The rotor 70 is non-rotatably connected to the rotor shaft 60 on that side of the rotor shaft 60 facing away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com