Tunnel baking machine

A roaster, tunnel-type technology, used in roasting, cleaning/oiling machinery, food ovens, etc., can solve problems such as residue sticking and affecting the cleanliness of conveyor belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

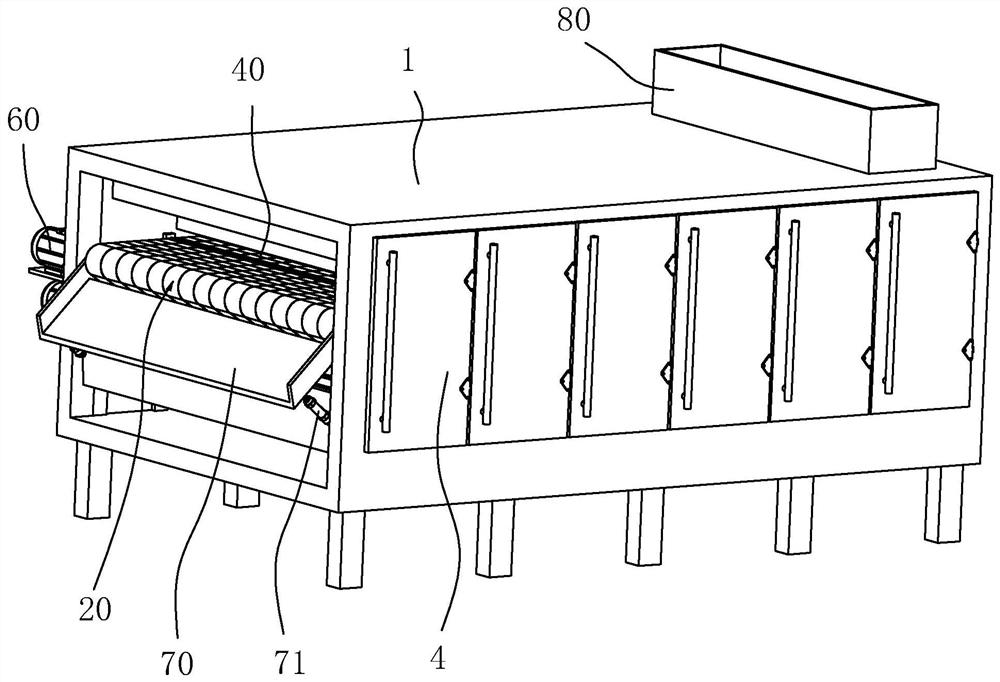

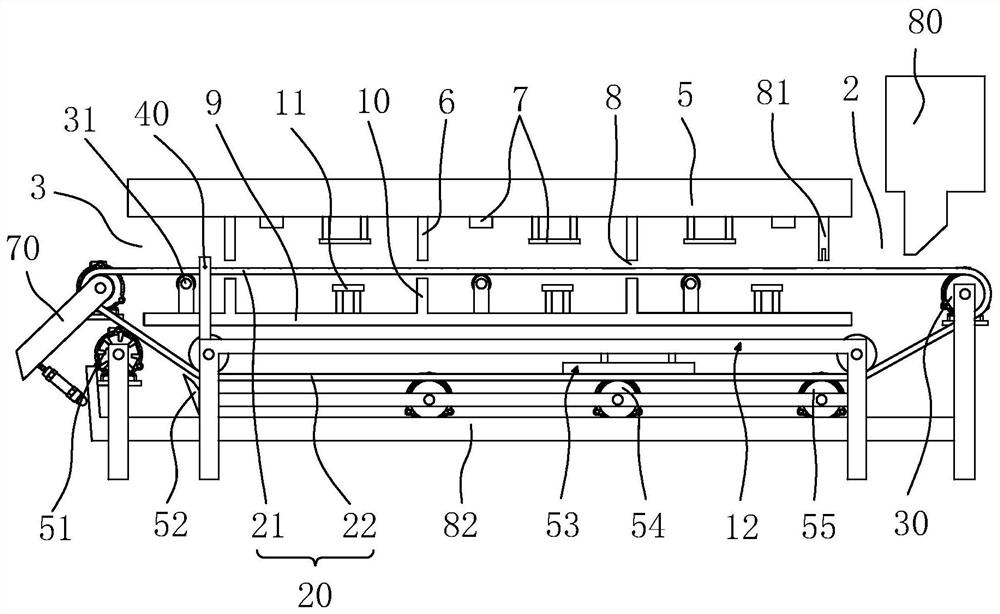

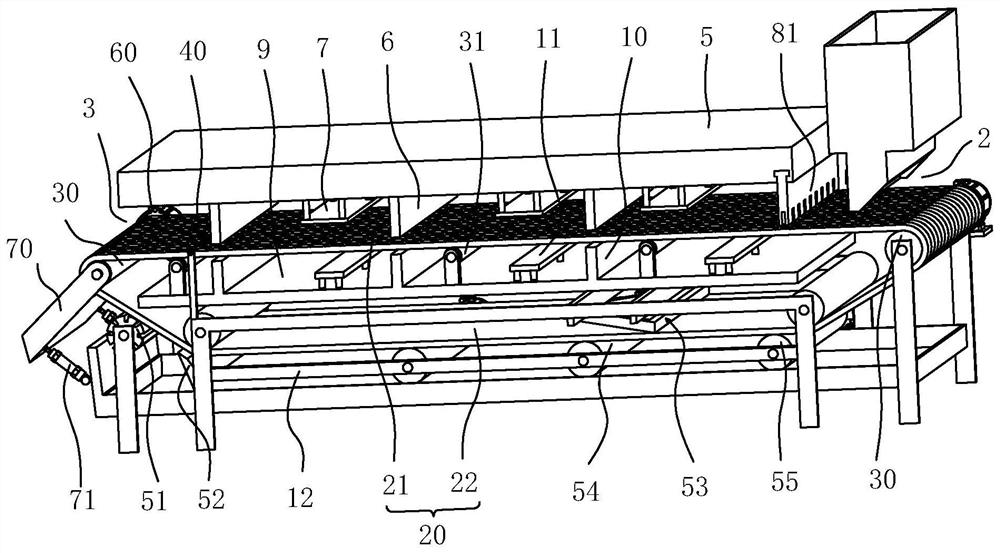

[0041] The following is attached Figure 1-5 The application is described in further detail.

[0042] The Chinese patent with the notification number CN206380545U discloses related technologies, a biscuit tunnel oven baking system with segmental temperature control, including a biscuit conveyor belt, a biscuit roll forming machine located at the front end of the biscuit conveyor belt, and a biscuit roll forming machine located at the rear end of the biscuit roll forming machine. Biscuit Tunnel Oven. During the biscuit baking process driven by the biscuit conveyor belt, biscuit and other residues are easy to stick to the conveyor belt, causing biscuit crumbs to remain on the conveyor belt, which in turn affects the cleanliness of the conveyor belt.

[0043] The embodiment of the present application discloses a tunnel roaster.

[0044] refer to figure 1 , figure 2 , a tunnel oven, comprising a tunnel furnace 1 and a conveyor belt 20 and a conveyor roller 30 installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com