A deflash shaker for collagen ice pucks

A collagen and burr removal technology, applied in the field of screen mesh, can solve problems such as burr residue, save production costs, save manual processing links, and facilitate production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

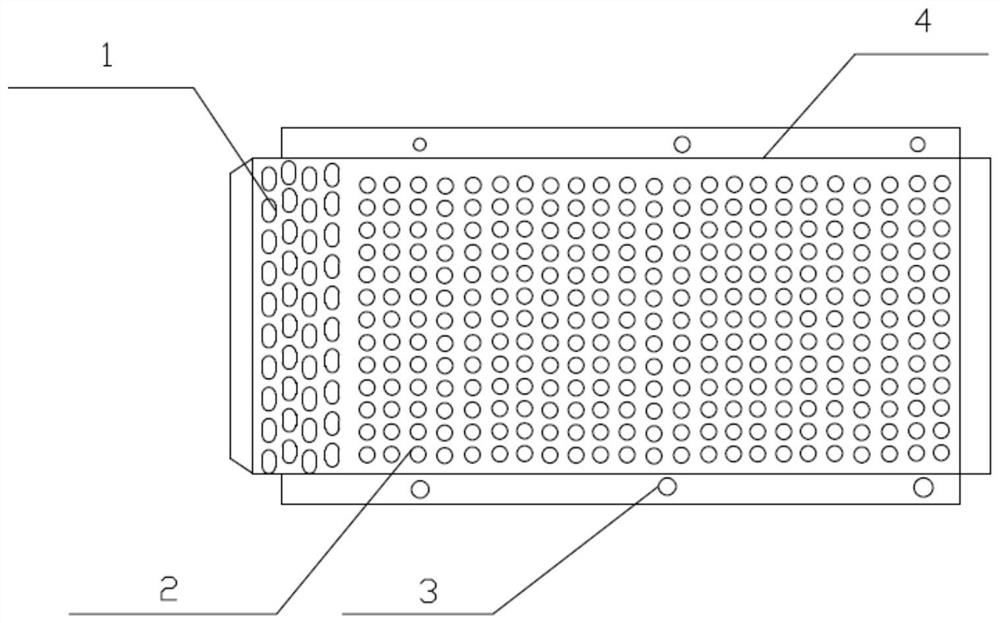

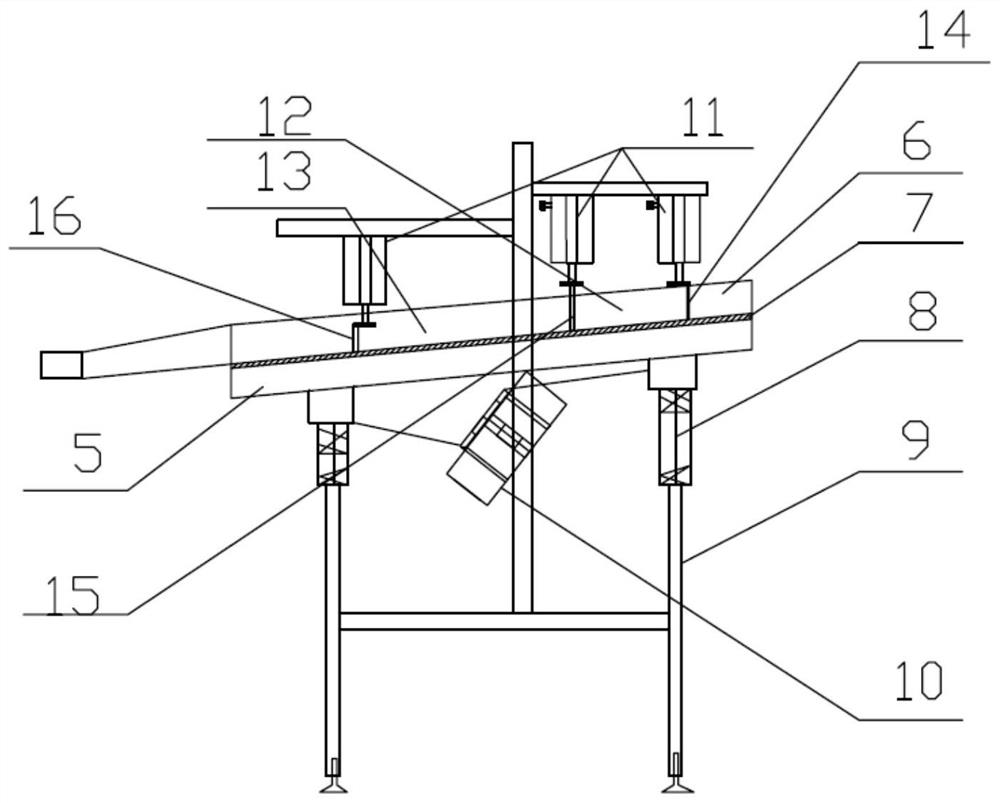

[0022] figure 1 The top view of the screen is given, as shown in the figure, there are two different mesh structures on this screen, 1 is a waist-shaped hole, and 2 is a round hole. combine figure 2 The side view of the whole machine shown, the circular hole is the vibrating ball area, the waist-shaped hole is the flash ice slag drop area behind the vibrating ball area, the diameter of the round hole is 4mm, and the diameter of the collagen ice ball is 12mm±0.5mm. With this size, the collagen ball will not get stuck in the round hole and cannot roll backward. The mesh screen 7 is fixed on the figure 2 Shown position, three retaining ball cylinders 11 and their respective connector baffles are fixed on the tripod 9, and the screen is divided into figure 2 For the three vibrating ball areas shown in 6, 12, and 13, in order to realize the independence of each area,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com