Cleaning device of die cutting machine cutter plate for packing case production

A technology for cleaning devices and packaging boxes, applied in the field of printing, can solve the problems of long cleaning time and complicated cleaning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

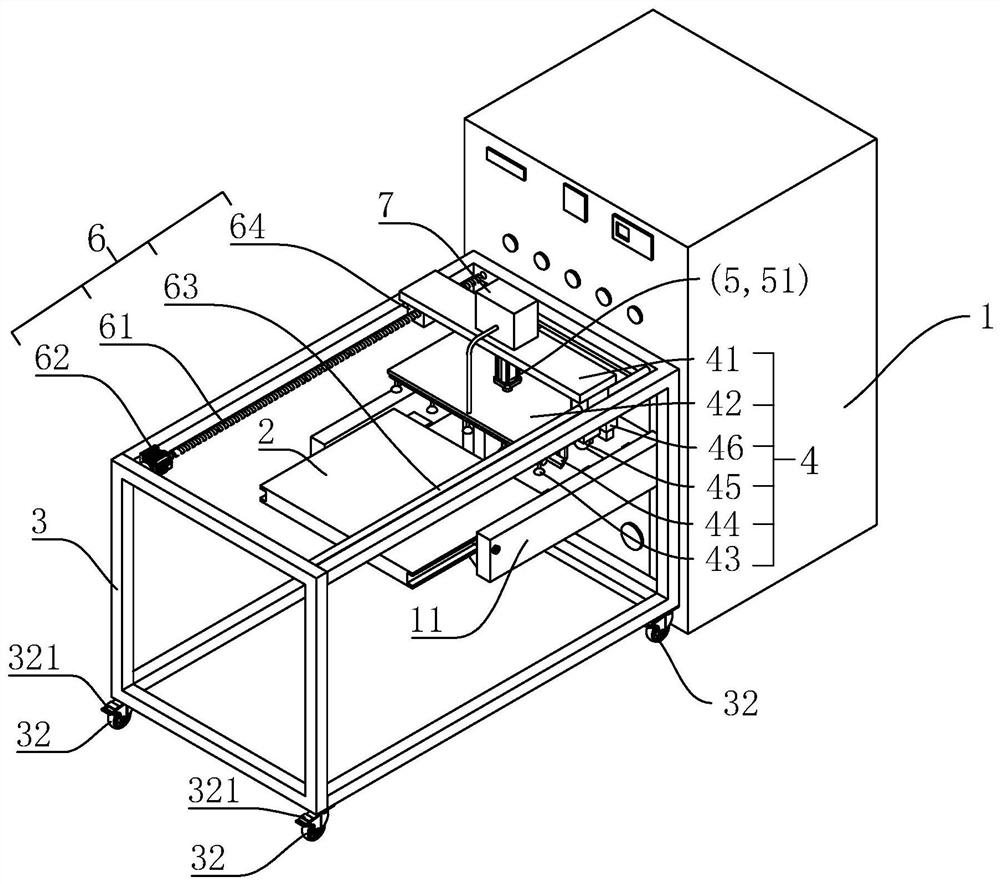

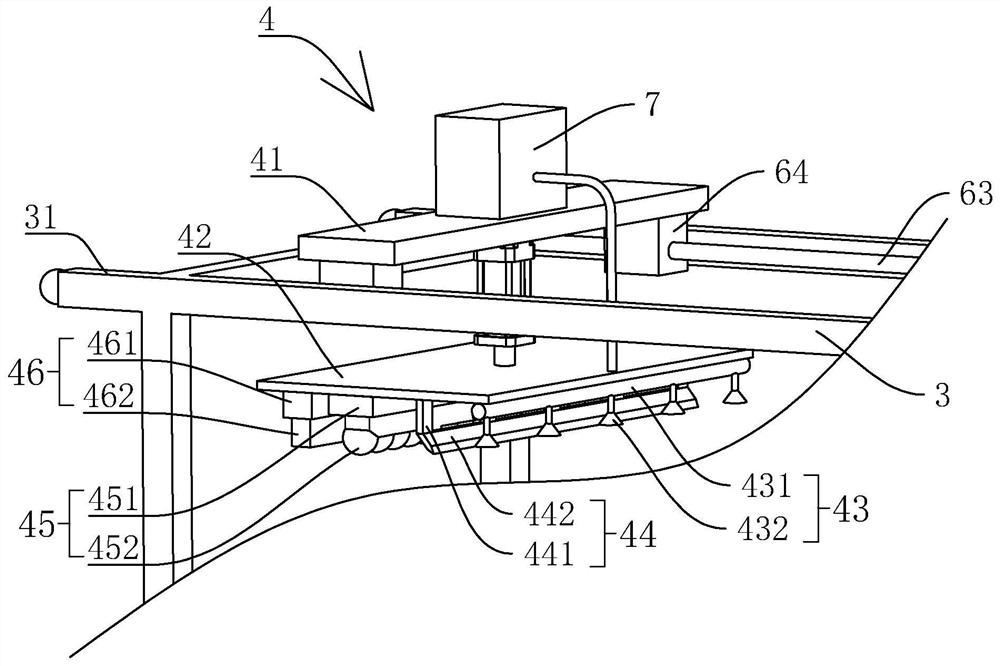

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] refer to figure 1 , is a cleaning device for a die-cutting machine knife plate for packaging box production disclosed by the present invention, comprising: a body 1, a die-cutting knife bottom plate 2, a moving frame 3, a cleaning assembly 4, a power part 5 and a driving assembly 6; the body 1 There is a bar-shaped opening along the horizontal direction, and the opposite sides of the bar-shaped opening in the length direction extend outwards and are welded with stainless steel chute plates 11, and the sides of the two chute plates 11 that are close to each other are provided with die cutters. The chute where the base plate 2 slides, the opposite sides of the die-cutter base plate 2 are slidably assembled between two chute plates 11, and the die-cutter base plate 2 can extend into the inside of the body 1 along the strip-shaped opening; the moving frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com