Recycled polypropylene material and preparation method thereof

A technology for recycling polypropylene and recycled polypropylene, which is applied in the field of polypropylene materials and can solve the problems of incomplete compatibility of PP and no help in improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

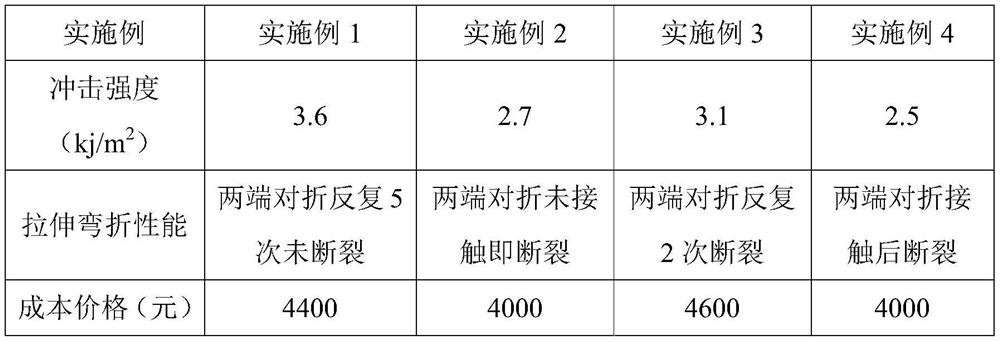

Examples

preparation example Construction

[0063] The second aspect of the present invention provides the preparation method of the recycled polypropylene material, comprising the following steps: after stirring the recycled polypropylene and the recycled polyethylene at 80-150°C for 1-20min, adding a toughening agent, an antioxidant agent and lubricant, continue to stir until the mixture is uniform; then extrude and granulate, that is to say.

[0064] In a preferred embodiment, the preparation method of the recycled polypropylene material comprises the following steps:

[0065] (1) Heat up the high-speed mixer to 120°C, then add recycled polypropylene and recycled polyethylene, and stir for 3 minutes; then add toughening agent, antioxidant and lubricant, and continue stirring for 30 seconds to obtain a mixed material;

[0066] (2) Put the mixed material into the extruder. The temperature of the twin-screw extruder is: 160°C in the first zone, 180°C in the second zone, 210°C in the third zone, 210°C in the fourth zone,...

Embodiment 1

[0071] Embodiment 1 provides a recycled polypropylene material. The raw materials for the preparation of the recycled polypropylene material include the following components: 85 parts of recycled polypropylene, 10 parts of recycled polyethylene, 5 parts of toughening agent, and 0.2 parts of antioxidant , 0.3 parts of lubricant.

[0072] The recycled polypropylene is obtained from waste woven bags and jumbo bags through conventional recycling; the recycled polyethylene is obtained from waste plastic films through conventional recycling; the toughening agent is a propylene-based elastomer selected from ExxonMobil Chemical industry, VistamaxxTM series, model 6102; the antioxidant is a combination of antioxidant 1010 and antioxidant 168, the weight ratio is 1:2; the lubricant is stearic acid.

[0073] The preparation method of described reclaimed polypropylene material comprises the following steps:

[0074] (1) Heat up the high-speed mixer to 120°C, then add recycled polypropyle...

Embodiment 2

[0077] Embodiment 2 provides a recycled polypropylene material. The raw materials for preparing the recycled polypropylene material include the following components: 90 parts of recycled polypropylene, 10 parts of recycled polyethylene, 0.2 part of antioxidant, and 0.3 part of lubricant.

[0078] The recycled polypropylene is obtained from waste woven bags and jumbo bags through conventional recycling; the recycled polyethylene is obtained from waste plastic films through conventional recycling; the antioxidant is a combination of antioxidant 1010 and antioxidant 168 , the weight ratio is 1:2; the lubricant is stearic acid.

[0079] The preparation method of described reclaimed polypropylene material comprises the following steps:

[0080] (1) Heat up the high-speed mixer to 120°C, then add recycled polypropylene and recycled polyethylene, and stir for 3 minutes; then add antioxidant and lubricant, and continue stirring for 30 seconds to obtain a mixed material;

[0081](2) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com