Fabricated building wall truss structure

A technology for building walls and truss structures, which is applied to truss structures, building components, building structures, etc., and can solve problems such as poor recycling rate of trusses, unoptimized support effects, and difficulty in changing internal support structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

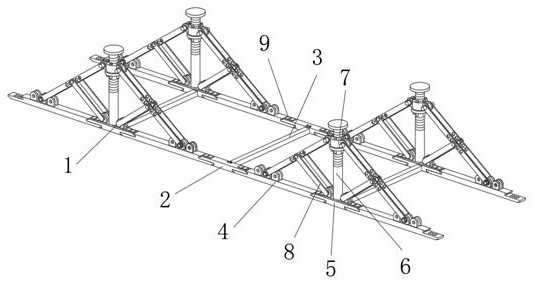

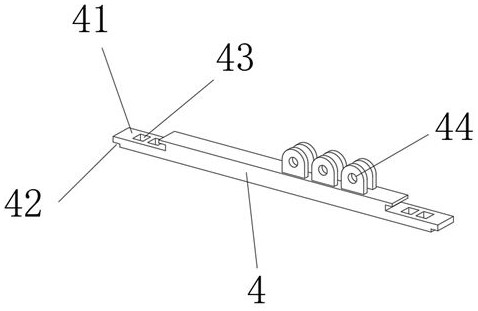

[0032] A prefabricated building wall truss structure, such as Figure 1-4As shown, it includes a triangular connection mechanism 1, and there are multiple groups of the triangular connection mechanism 1. A horizontal connecting plate 2 is arranged between two groups of horizontal triangular connecting mechanisms 1, and a horizontal connection plate 2 is arranged between two vertical groups of A longitudinal connecting plate 3 is arranged between them, and a plurality of installation blocks 9 are interspersed and connected to the upper end of the transverse connecting plate 2, and the transverse connecting plate 2 and the triangular connection mechanism 1 are clamped together by a plurality of installation blocks 9; The triangular connection mechanism 1 includes a support frame 4 and a connecting frame 5. There are two supporting frames 4, and a connecting frame 5 is arranged between the two supporting frames 4. The upper end of the connecting frame 5 is interspersed with a plur...

Embodiment 2

[0035] On the basis of Example 1, as Figure 5 As shown, a flower-shaped connecting groove 31 is opened at both ends of the longitudinal connecting plate 3, and one end of the longitudinal connecting plate 3 is sleeved in the slot 55 to engage with the flower-shaped connecting block 56 and the two connecting frames 5 are fixed by screws. Connection, the connection relationship between the longitudinal connecting plate 3, the transverse connecting plate 2 and the support frame 4 is the same as that of the connecting frame 5 and the supporting frame 4, and the connection relationship between the transverse connecting plate 2 and the longitudinal connecting plate 3 is the same as that between the connecting frame 5 and the longitudinal The connection relationship between the connecting plates 3 is the same, by making the structural design of the transverse connecting plate 2 the same as that of the connecting frame 5, and the installation method between the longitudinal connecting...

Embodiment 3

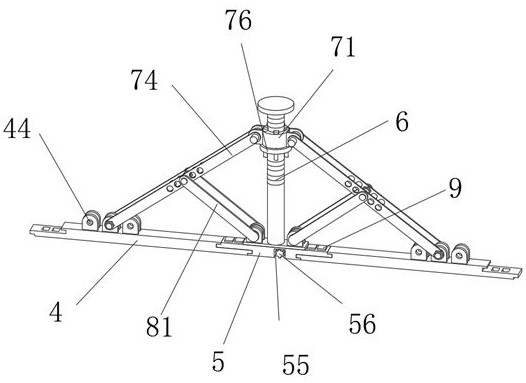

[0037] On the basis of Example 2, such as Figure 6 As shown, the bending mechanism 7 includes a sliding ring 71 and an adjusting ring 76. The upper end of the sliding ring 71 is interspersed with a plurality of limit rods 72. The limit rods 72 are distributed in a circular array around the center of the slide ring 71. The slide ring 71 Two connecting lugs 73 are uniformly formed on both sides of the outer surface of the outer surface, and the outer sides of the two connecting lugs 73 are connected with a curved rod 74 through the rotation of the rotating shaft. The middle part of the curved rod 74 has a plurality of connecting holes 75, an adjusting ring 76 and a sliding The diameters of the rings 71 are the same, and the upper end of the adjusting ring 76 is provided with a plurality of limit holes 77 that pass through up and down, and the limit holes 77 correspond to the positions of the limit rods 72; One end of the rod 74 away from the connecting ear 73 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com