Crankshaft horizontal output general gasoline engine

A general-purpose gasoline engine, horizontal output technology, applied in the direction of mechanical equipment, engine components, engine cooling, etc., can solve the problems of aggravating the evaporation rate of fuel in the fuel tank, corrosion, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

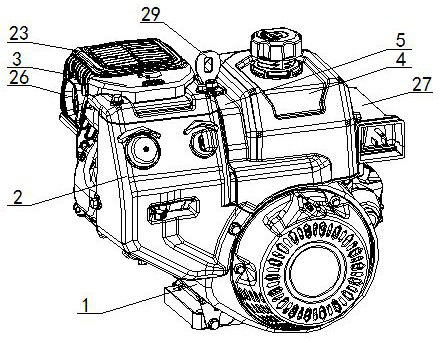

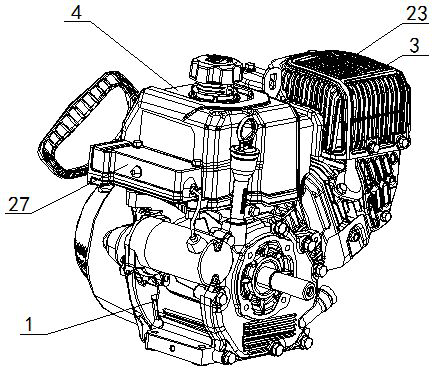

[0044] Embodiment 1: as figure 1 , 2 As shown, a general-purpose gasoline engine with crankshaft horizontal output includes an engine body 1, a panel 2 and a muffler cover 3 are arranged on one side of the engine body 1, and a fuel tank body 35 is arranged on the other side of the engine body 1 , the fuel tank body 35 is covered with a fuel tank cover 4, the panel 2 is arranged on the front end surface of the engine body 1 side, the muffler cover 3 is located above the panel 2 and the front end of the muffler cover 3 is buckled on the upper end surface of the panel 2 , the left side of the fuel tank cover 4 is engaged with the right side of the muffler cover 3 and the right side of the panel 2 .

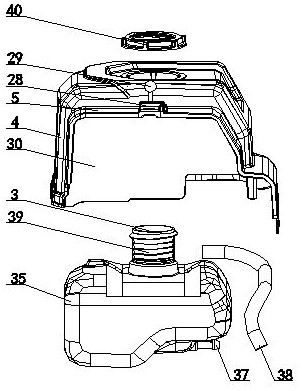

[0045] Such as image 3 , 4 As shown, wherein, the fuel tank body 35 and the fuel tank cover 4 are assembled like this: a fuel filler port 36 is vertically provided on the fuel tank body 35, an oil outlet 37 is provided on the lower end surface of the fuel tank body 35, An oil pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap