Laser radar full-automatic detection system suitable for intelligent production line

A technology of laser radar and detection system, applied in the direction of radio wave measurement system, instrument, etc., can solve problems such as laser echo interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

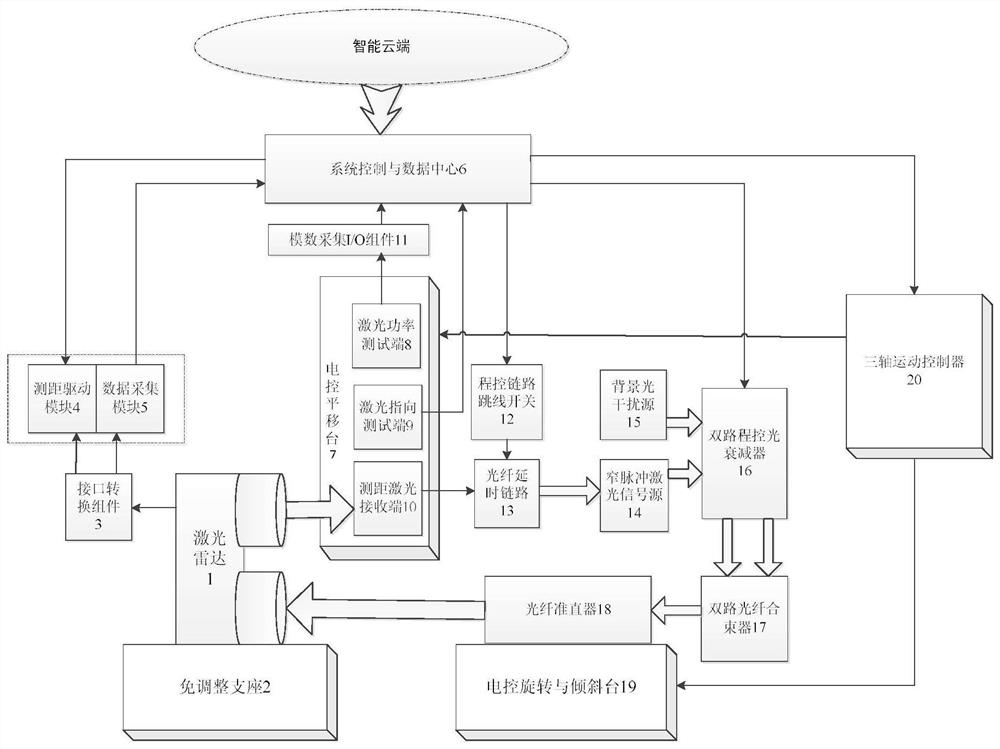

[0020] Such as figure 1As shown, a laser radar automatic detection system suitable for intelligent production lines, including laser radar 1, adjustment-free support 2, interface conversion component 3, ranging drive module 4, data acquisition module 5, system control and data center 6. Electronically controlled translation platform 7, laser power test terminal 8, laser pointing test terminal 9, ranging laser receiving terminal 10, modulus acquisition I / O component 11, program-controlled link jumper switch 12, optical fiber delay link 13 , narrow pulse laser signal source 14, background light interference source 15, dual path control optical attenuator 16, dual optical fiber beam combiner 17, optical fiber collimator 18, electric control rotation and tilt table 19 and three-axis motion controller 20 , wherein the laser radar 1 is fixed on the adjustment-free support 2, the electrical interface of the laser radar 1 is connected to the interface conversion assembly 3, the interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com