Engine hood vibration optimization design method

An engine cover and optimization design technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as difficulty in finding the cause and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

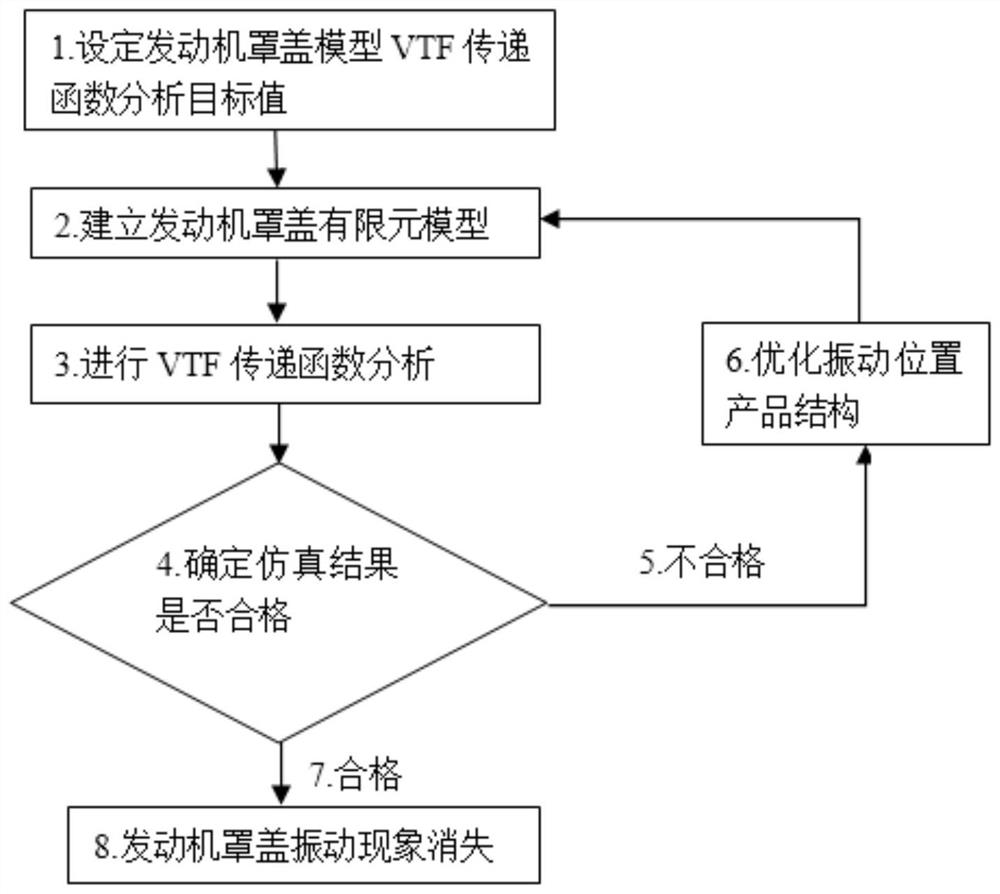

[0032] A vibration optimization design method for an engine cover, comprising the following steps:

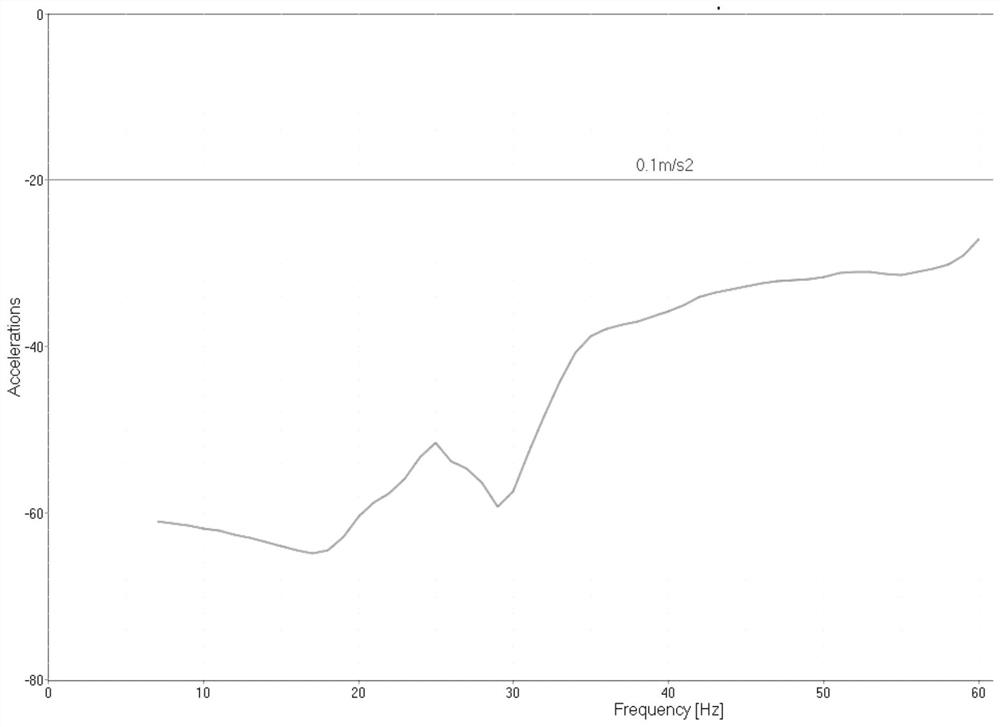

[0033] Step 1. Analyze the VTF transfer function of the engine cover of the benchmark model through simulation. The target value of the VTF function of a certain model in the range of 0-60Hz is 2 , see figure 2 .

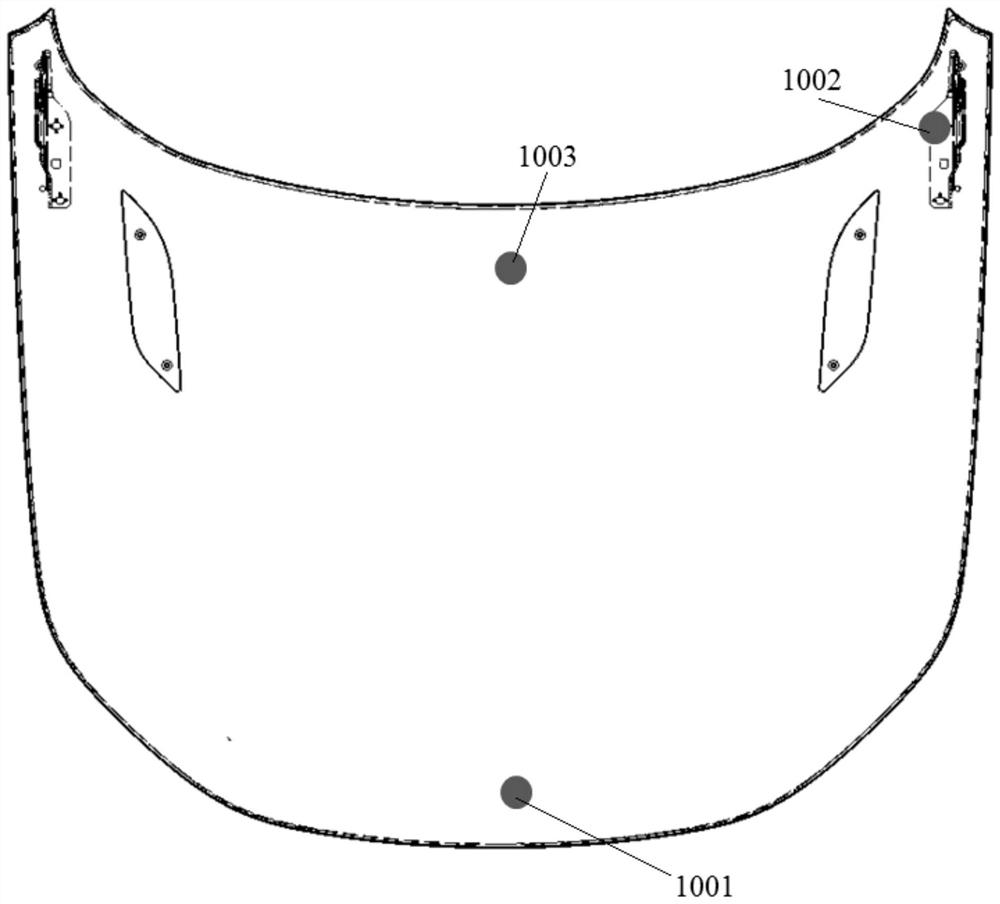

[0034] Step 2: Establish a finite element model with the inner panel, outer panel, and local reinforcements of the engine hood. The inner and outer panels are connected by hemming process, and the inner panel and the reinforcement are connected by electric welding process to define the engine hood The connection point between the cover and the body is the excitation point, including the lock connection 1001 and the hinge connection 1002, and the structural weak point 1003 is the response point (the midpoint directly above the symmetrical plane of the Y direction of the sealing surface), see image 3 .

[0035] Step 3, using Nastran software for VTF transfer functi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap