Variable displacement rotary vane pump

A rotary vane pump, variable technology, applied in the field of oil pumps, can solve the problems of reducing pump efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

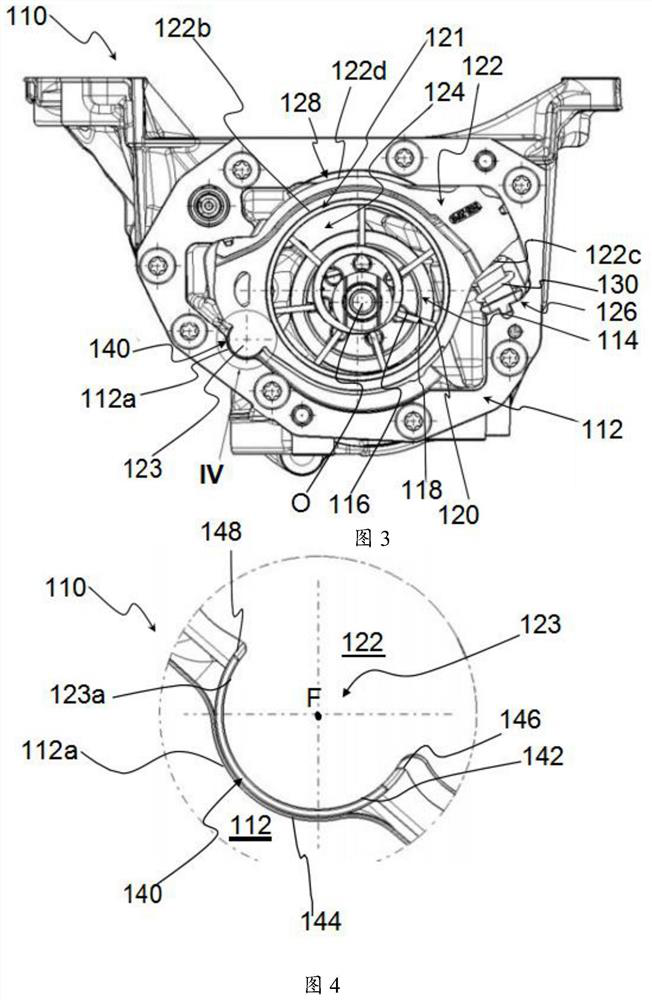

[0039] First refer to image 3 and Figure 4 , shows a first embodiment of a variable displacement rotary vane pump (in particular, a variable displacement oil pump) according to the present invention. The pump is indicated by numeral 110 .

[0040] The pump 110 includes a pump body 112 inside which a rotor 114 rotates. The rotor 114 is provided with radial cavities 116 in which vanes 118 slide. For clarity of illustration, reference numerals 116 and 118 are associated with only one of the radial cavities and one of the vanes shown.

[0041] The rotor 114 is rotatable about the axis of rotation O inside the pump body 112 .

[0042] The swing stator 122 is arranged in an eccentric position around the rotor 114 . The swing stator 122 is movable around a fulcrum 123 inside the pump body 112 .

[0043]The radially outer ends 120 of the blades 118 contact a ring 121 inserted between the rotor 114 and the oscillating stator 122 . The ring 121 is in contact with the radially i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap