Fire prevention and control system for lithium ion battery prefabricated cabin and control method

A lithium-ion battery and prefabricated cabin technology, applied in the field of fire extinguishing, can solve the problems of waste of resources, increase the volume of lithium battery packs, and separate occupation, etc., and achieve the effect of rapid cooling and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

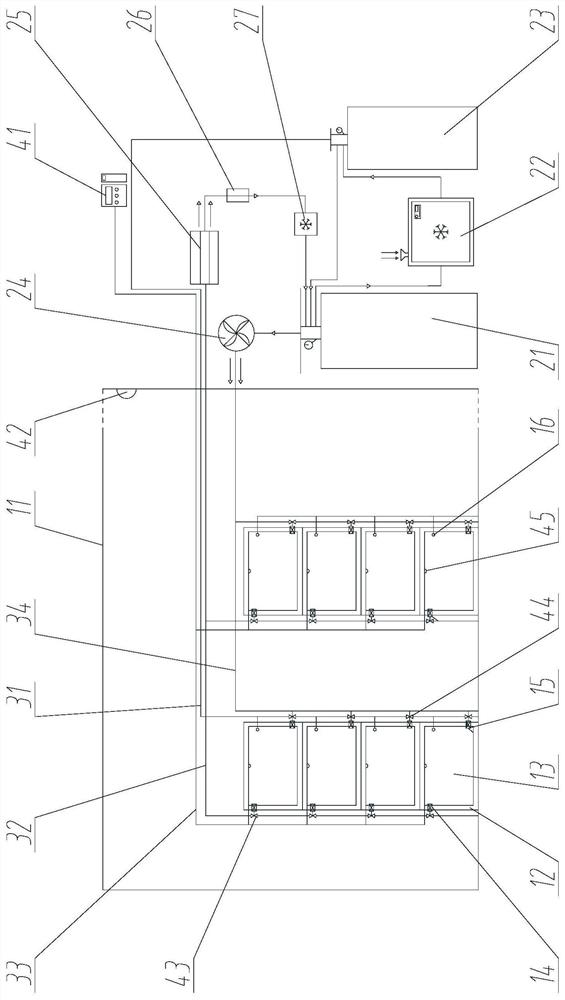

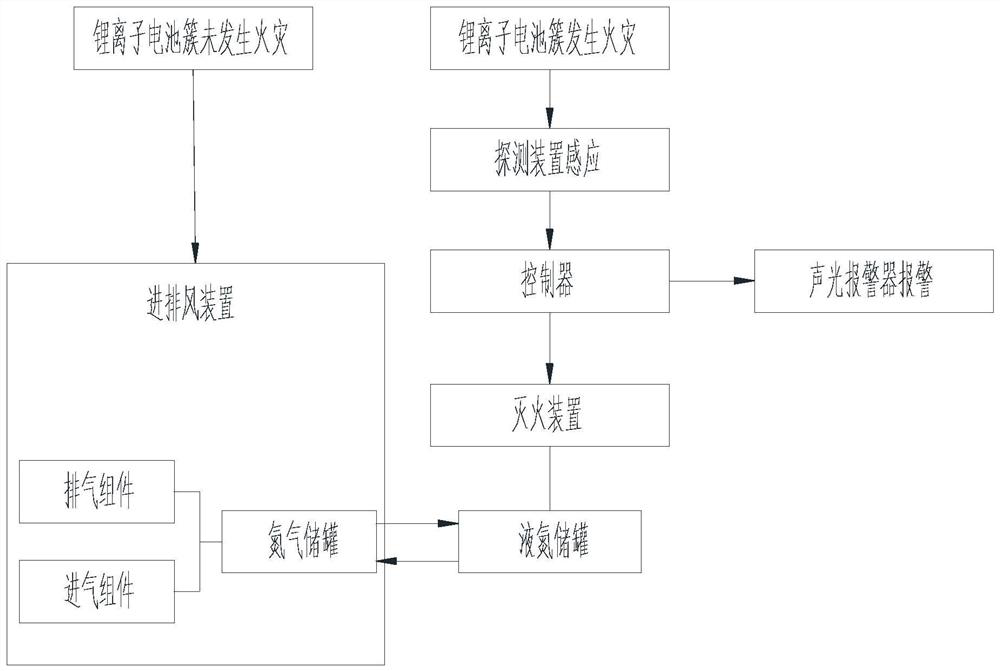

[0035] Such as figure 1 As shown, the fire prevention and control system for a lithium-ion battery prefabricated cabin includes battery components, control components, air intake and exhaust devices, and fire extinguishing devices;

[0036] The battery assembly is arranged in the battery prefabricated cabin body 11, including a plurality of battery energy storage cabinets 12 arranged in a row, and each battery energy storage cabinet 12 is divided into a plurality of grids arranged up and down, and each grid is provided with Air inlet 15, exhaust outlet 14 and liquid nitrogen injection device 16, are provided with lithium ion battery cluster 13 in it;

[0037] The air intake and exhaust device includes a nitrogen storage tank 21, an exhaust assembly 25 and an intake assembly 24. After the output end of the nitrogen storage tank 21 is connected to the intake assembly 24, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com