Stone breaking machine used for hydraulic engineering building

A technology used in water conservancy projects and construction, applied in grain processing, etc., can solve the problems of manpower consumption, inability to realize automatic feeding of raw materials, and inconvenient crushing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

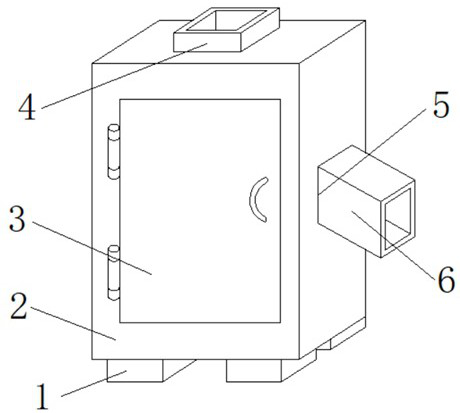

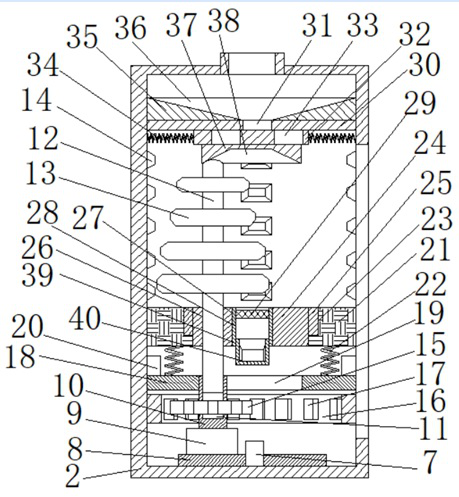

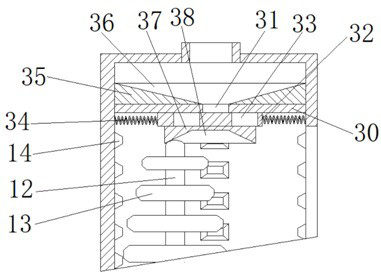

[0031] refer to Figure 1-7 , a stone crushing machine for water conservancy construction, comprising several bases 1, the tops of several bases 1 are jointly fixed with the same shell 2, the front side of the shell 2 is rotatably installed with a box door 3, and the top of the shell 2 is provided with Feed port 4, feed port 4 is used to put stone raw materials into the stone crushing machine, a first through hole 5 is opened on one side of the shell 2, and a discharge pipe 6 is fixedly installed in the first through hole 5, and the shell 2 A fixed rod 7 is fixedly installed on the inner wall of the bottom of the housing, and a turntable 8 is installed on the fixed rod 7. The fixed rod 7 is used as the rotation axis of the turntable 8, and the turntable 8 is rotatably installed on the bottom inner wall of the shell 2. Motor 9, the output shaft of motor 9 faces upwards, and the output shaft of motor 9 is fixedly installed with connecting seat 10, is provided with the first chut...

Embodiment 2

[0042] refer to Figure 1-7 , a stone crushing machine for water conservancy construction, including several bases 1, the tops of several bases 1 are jointly welded with the same shell 2, the front side of the shell 2 is rotatably installed with a box door 3, and the top of the shell 2 is provided with an inlet The feed port 4 and the feed port 4 are used to put stone raw materials into the stone crushing machine. A first through hole 5 is opened on one side of the shell 2, and a discharge pipe 6 is welded in the first through hole 5. The bottom of the shell 2 A fixed rod 7 is welded on the inner wall, and a turntable 8 is installed on the fixed rod 7. The fixed rod 7 is used as the rotation axis of the turntable 8. The turntable 8 is rotatably installed on the bottom inner wall of the shell 2. The top of the turntable 8 is fixed with a motor by screws. 9. The output shaft of the motor 9 faces upwards, and a connecting seat 10 is welded on the output shaft of the motor 9. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com