Product classification and discharging mechanism based on BIN grade

A product classification and level technology, applied in sorting and other directions, can solve problems such as low efficiency, stability and accuracy cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

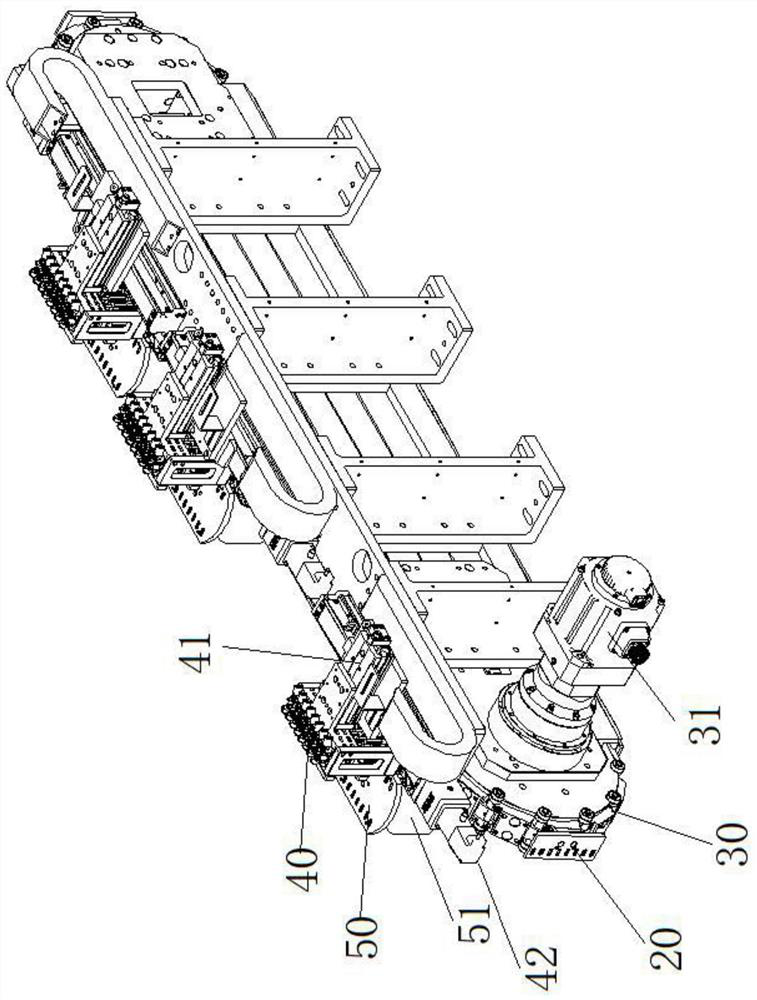

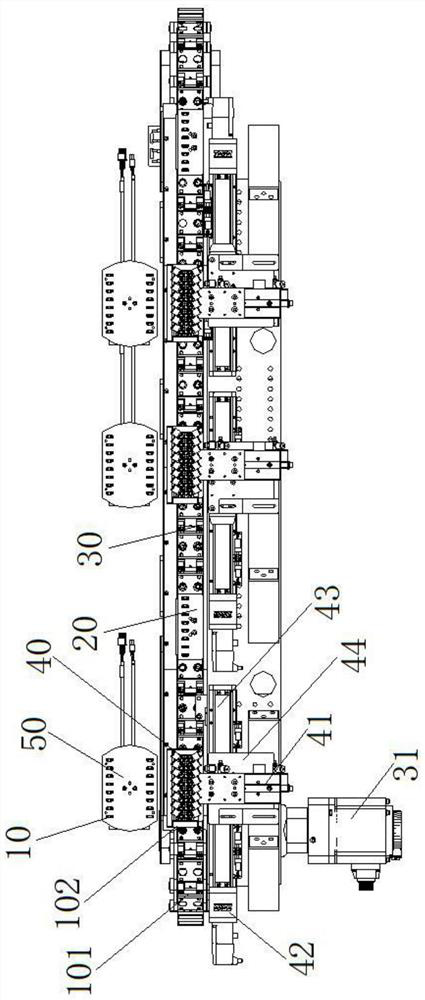

[0026] see figure 1 and figure 2 , as shown in the legend, a BIN-level product classification blanking mechanism, including:

[0027] a carrier unit comprising a plurality of carriers 20 for carrying products 10;

[0028] A conveying unit, which includes a circular conveying device 30 for driving a plurality of carriers 20 to move and sequentially pass through a loading station 101 and a plurality of unloading stations 102, and each unloading station corresponds to at least one product of the same BIN level ;

[0029] A transfer unit, which includes a plurality of transfer devices 40 for transferring products, each transfer device 40 corresponds to at least one product of the same BIN level;

[0030] A cache unit, which includes a plurality of cache platforms 50 for carrying products, each cache platform 50 corresponding to at least one product of the same BIN level;

[0031] Each product is transported to the corresponding unloading station by the carrier 20 and the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com