Compartment tarpaulin overturning and covering equipment

A flipping cover and tarpaulin technology, which is applied to motor vehicles, load coverage, and vehicles used for freight, can solve the problems of unfavorable tarpaulin cover collection efficiency, danger, and difficulty in meeting freight requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

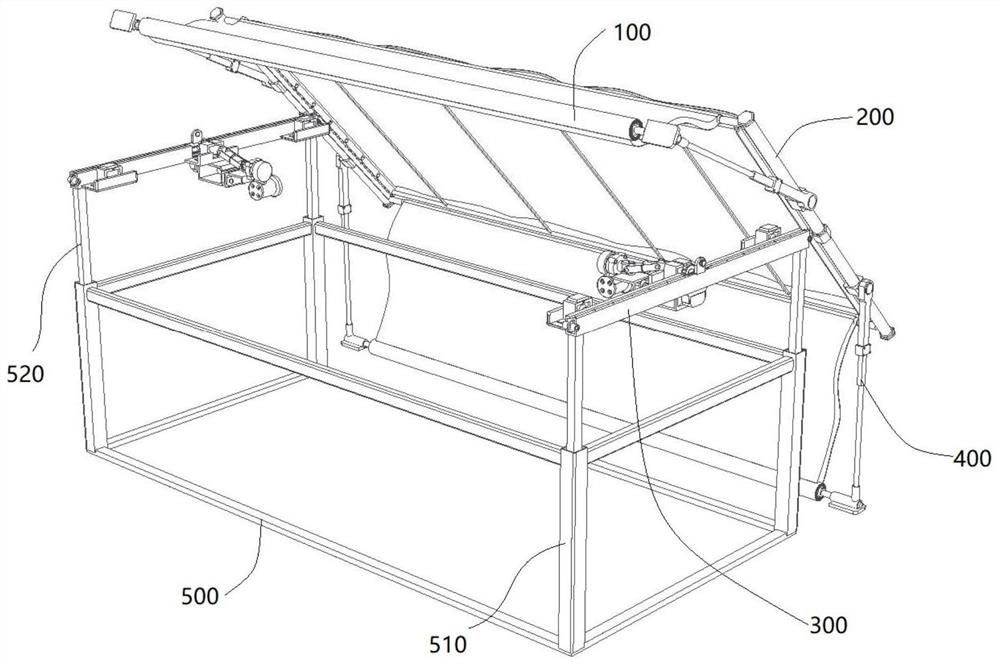

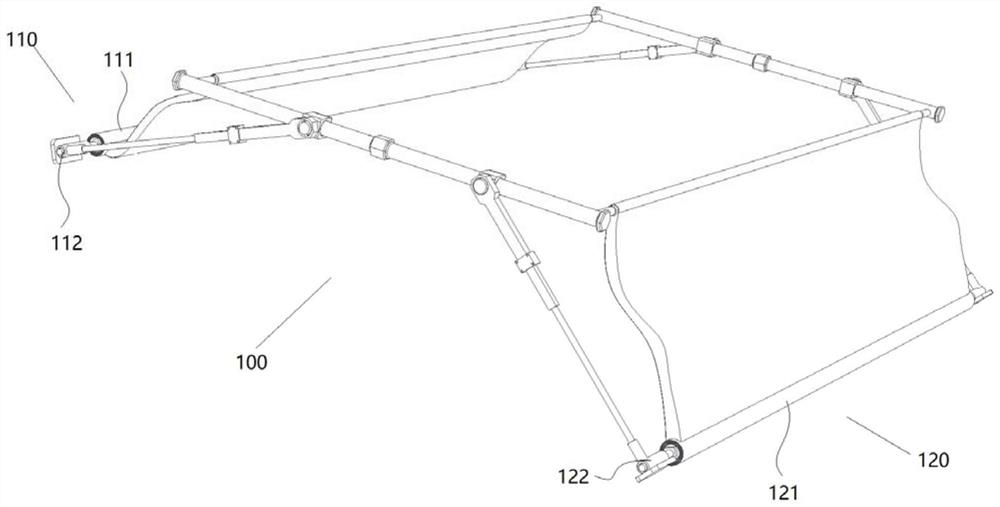

[0042] As a preferred embodiment of the present invention, the vehicle tarpaulin flipping and covering device also includes a support frame 300, the support frame 300 is arranged around the vehicle compartment, and the tarpaulin cover 200 and the support frame 300 Relatively movable to switch the tarpaulin cover 200 between the first position and the second position.

[0043] In this embodiment, there are the following two connection modes between the tarpaulin cover 200 and the support frame 300:

Embodiment approach 1

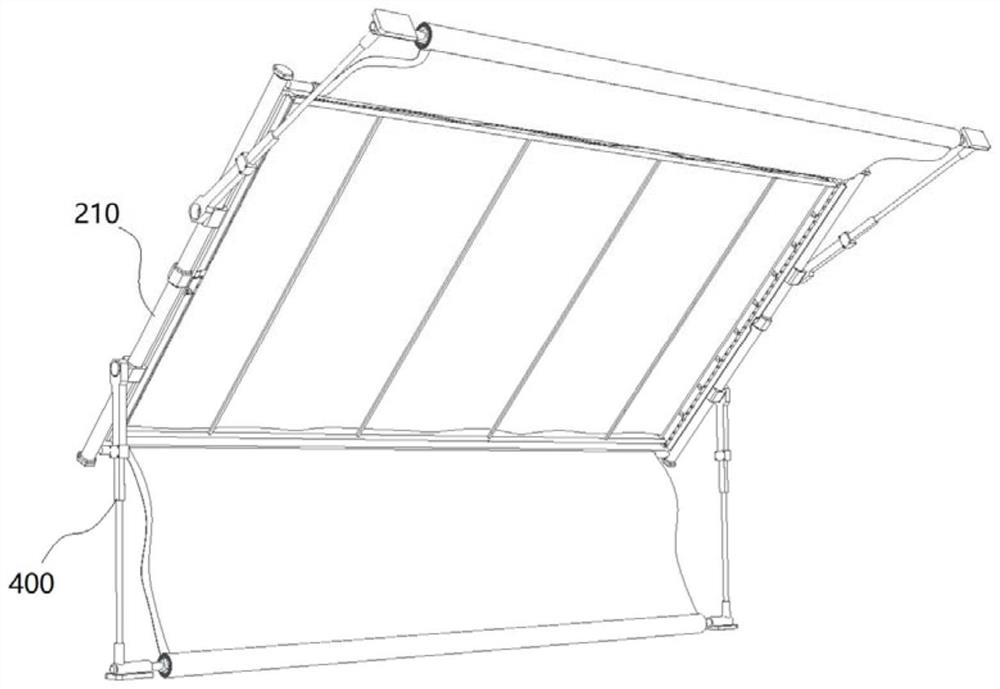

[0045]The tarpaulin cover 200 includes a beam 210, and the beam 210 is provided with a sprocket; the support frame 300 includes a support rod 310, and the support rod 310 is provided with a chain 311, and the sprocket is matched with the chain 311 .

Embodiment approach 2

[0047] The tarpaulin cover 200 includes a crossbeam 210, and the crossbeam 210 is provided with a slider; the support frame 300 includes a support rod 310, and the support rod 310 is provided with a chute, and the slider is matched with the chute .

[0048] In one embodiment, no matter which of the above-mentioned implementations is adopted, a driving part can be provided on the beam 210 to drive the tarpaulin cover 200 to move relative to the support frame 300. Wherein, the driving part may be a motor or a hydraulic cylinder, and this embodiment does not limit the structure of the driving part.

[0049] As a preferred embodiment of the present invention, the equipment for turning over and covering the compartment tarpaulin further includes: a telescopic rod 400, one end of the telescopic rod 400 is rotatably connected to the beam 210, and the other end of the telescopic rod 400 is connected to the The cloth rolling device 100 is rotatably connected.

[0050] As a preferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com