Method for determining position of laser welding focus

A focus position, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inaccurate reflection of laser energy density, inaccurate focus position selection, cumbersome focusing process, etc., to save image acquisition and processing time, avoiding the error of subjective judgment by the naked eye, and the effect of high image clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art.

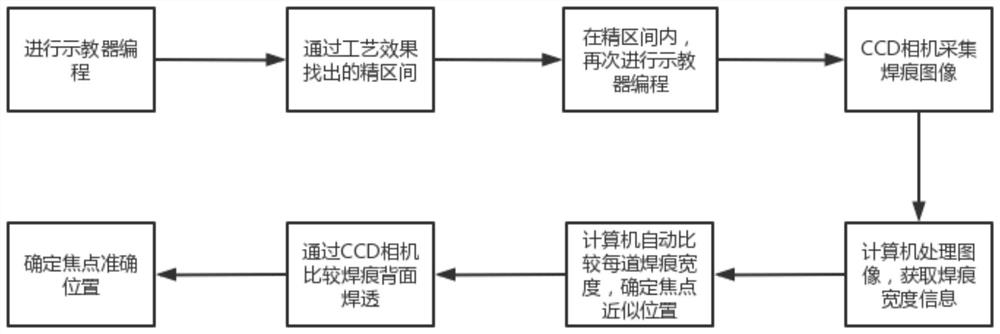

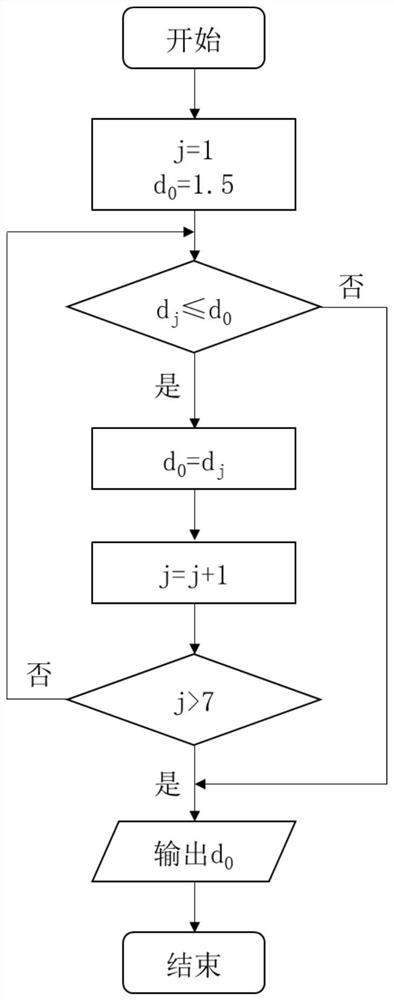

[0041] see figure 1 , 2 As shown, a method for determining the focus position of laser welding is used to determine the focus position of a laser head. This method is mainly used for laser welding equipment used for the first time. After the focus position is determined (with an error of less than 1mm), high-precision laser welding operations can be performed.

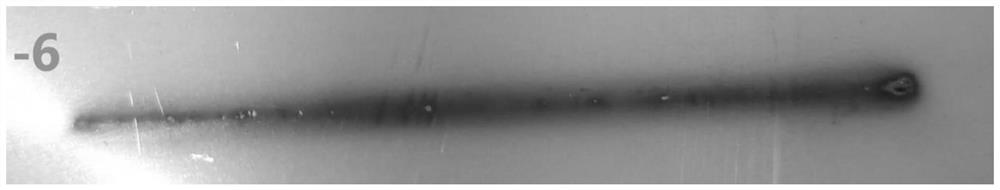

[0042] The basic principle of this method is: SUS304 stainless steel plate has an absorption rate of up to 95% of laser energy, and the laser head is controlled by a robotic arm to weld a weld mark with a length of about 5cm on the stainless steel, and the laser energy received at the starting point of the weld mark is the largest, The energy behind is stable, cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com