Packaging box and packaging material

A packaging material and packaging box technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of tight space reserved for installing packaging covers, increased drinking, and limited area of small-volume packaging containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

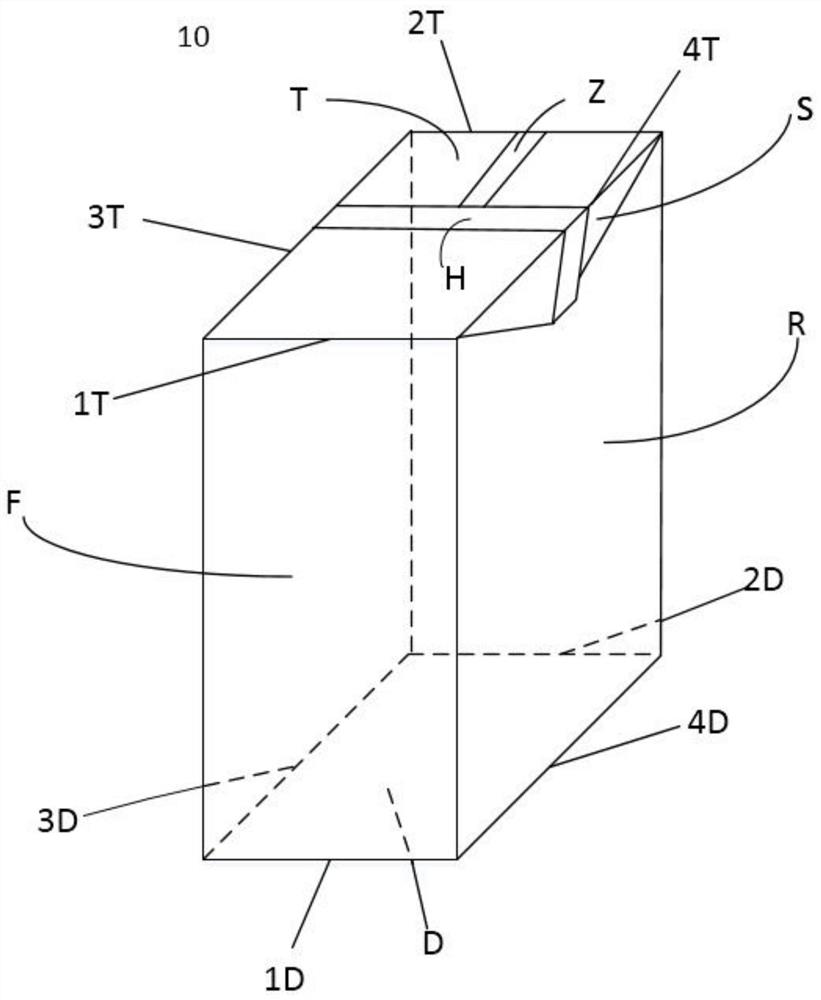

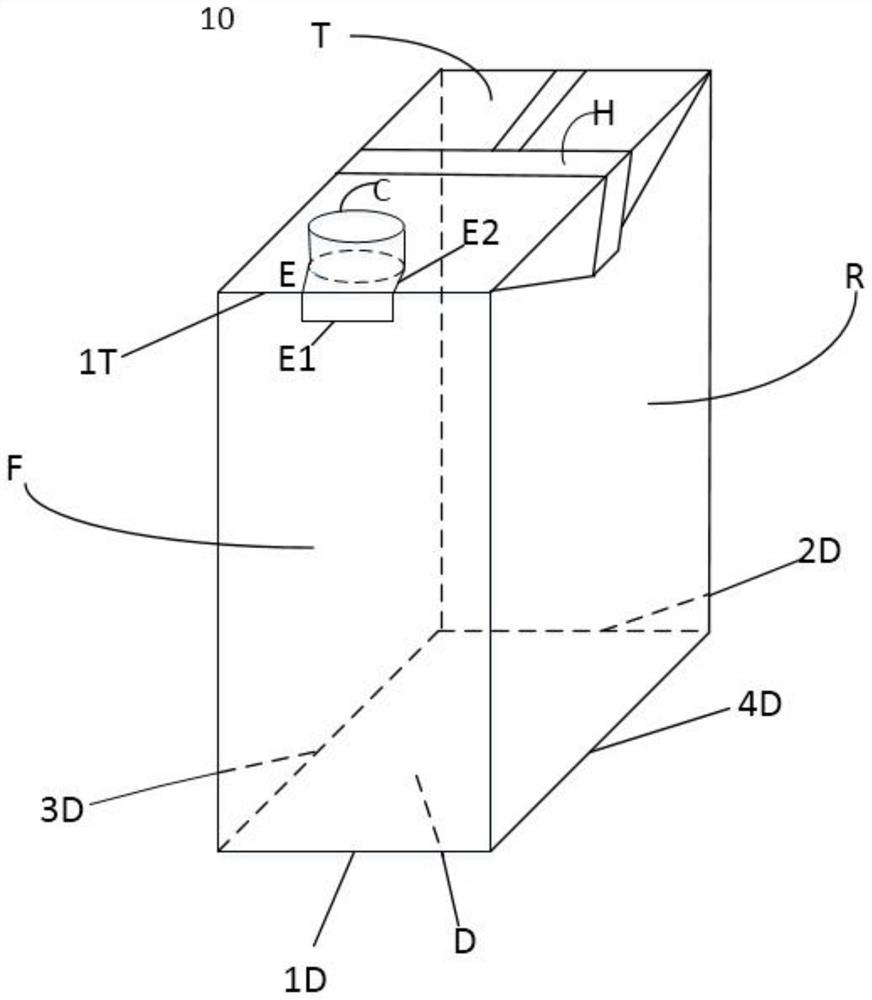

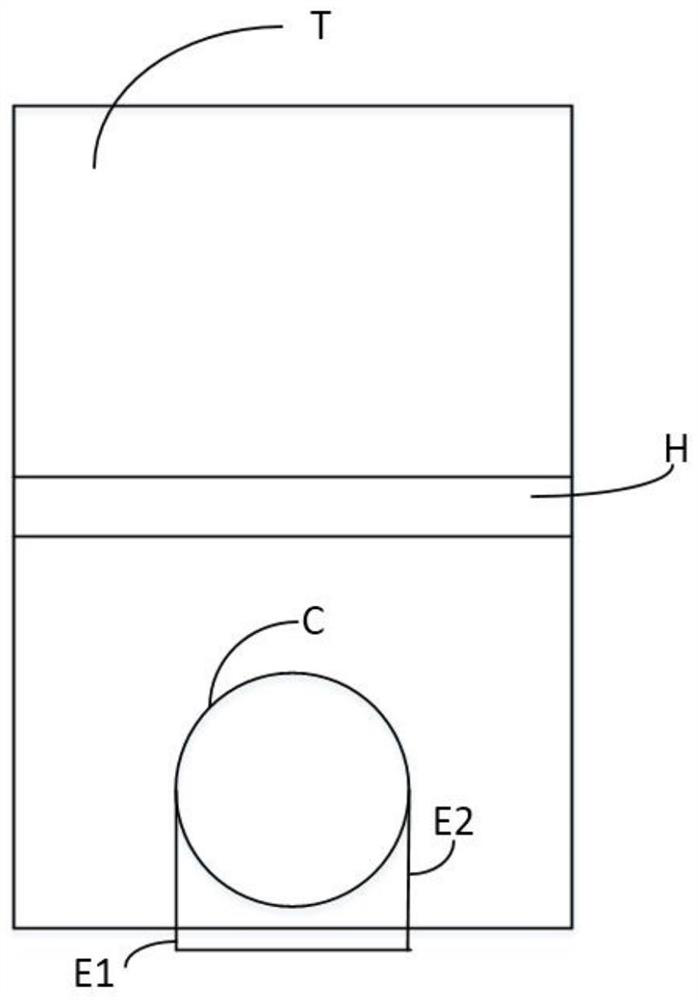

[0040] figure 1 Shown is a three-dimensional schematic diagram of a packaging box 10 according to an embodiment of the present invention. Packet 10 is generally formed from a web of paper-based composite packaging material. On the filling machine, the forming equipment gathers the longitudinal edges of both sides of the coil and glues them at the edges to form a longitudinal seal. The mechanism horizontally seals the material tubes at fixed distances sequentially, forming horizontal seals at both ends of the sealed package, cutting and shaping the horizontal seals to form individual liquid beverage packaging boxes. After being formed into a packaging box, the horizontal seals are respectively located on the top and bottom plates of the packaging box, and the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com