A straw mat winder for mass production of straw mats

A batch and winder technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of uneven straw mats, labor-intensive, straw mat wrinkles, etc., to avoid wrinkles and simple operation , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

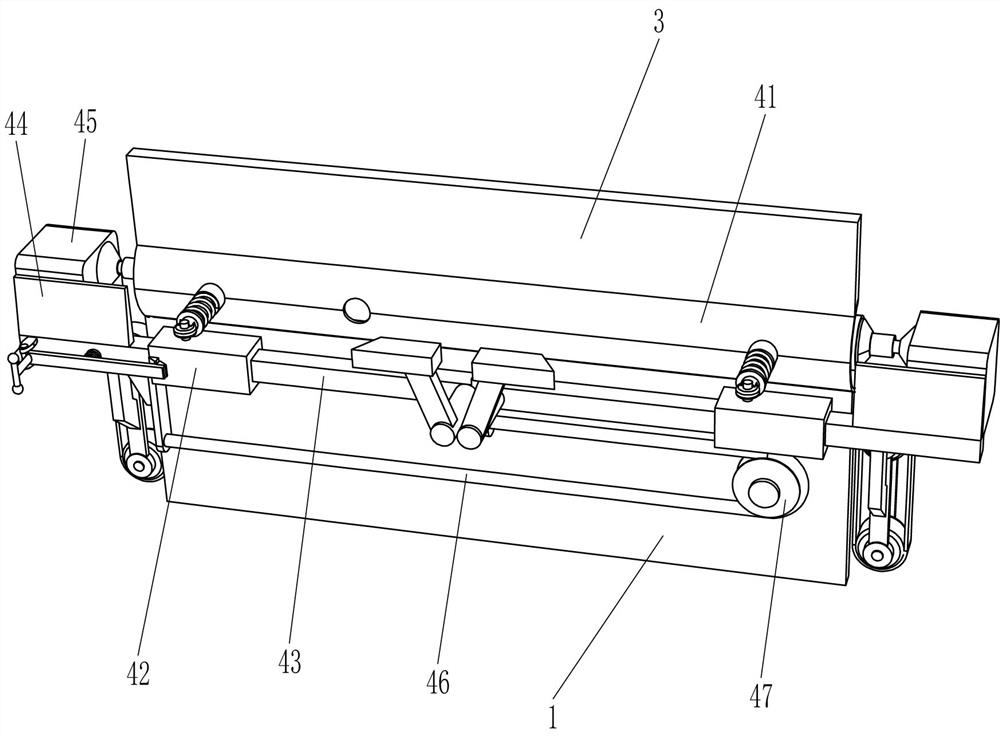

[0030] A straw mat winder for mass production of straw mats, such as Figure 1-6 As shown, it includes bracket 1, inclined plate 2 and baffle 3, the top of bracket 1 is connected with inclined plate 2, the right side of inclined plate 2 is connected with baffle 3, and also includes winding mechanism 4 and clamping mechanism 5. The plate 2 is provided with a winding mechanism 4 , and the winding mechanism 4 is provided with a clamping mechanism 5 .

[0031] The winding mechanism 4 includes an arc plate 41, a sliding sleeve 42, a sliding rod 43, a mounting plate 44, a deceleration motor 45, a pulling rope 46, a wire wheel 47, a damping rod 48, a damping tube 49 and a slotted tube 410. 2. An arc-shaped plate 41 is embedded in the right side, and two sliding sleeves 42 are connected to the right side of the bottom of the inclined plate 2. The two sliding sleeves 42 are arranged in front and rear. The sides of the rods 43 away from each other are connected with a mounting plate 44...

Embodiment 2

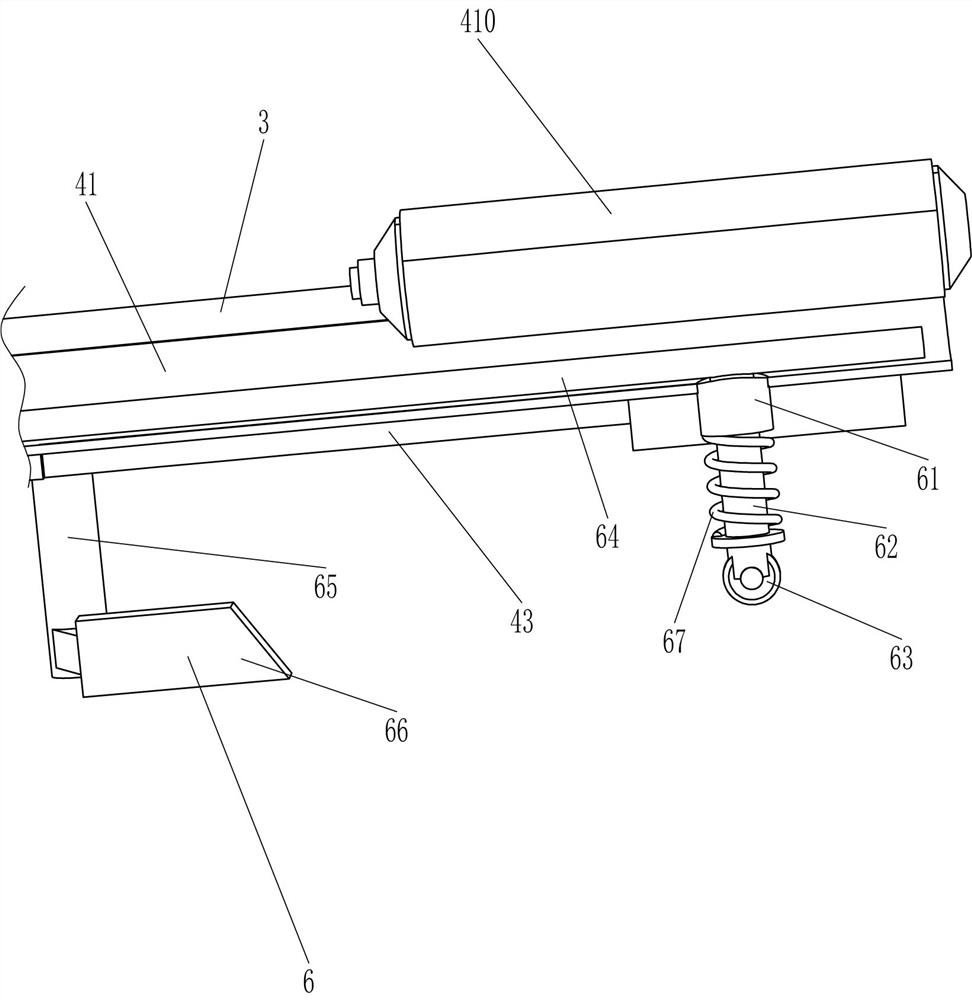

[0035] On the basis of Example 1, as Figure 7As shown, it also includes a push-up mechanism 6. The push-up mechanism 6 includes a guide sleeve 61, a guide rod 62, a contact wheel 63, a push plate 64, a connecting rod 65, a wedge-shaped block 66 and a second spring 67. The arc-shaped plate 41 A guide sleeve 61 is embedded in the front and rear parts, a guide rod 62 is slidably connected in the guide sleeve 61, a contact wheel 63 is rotatably connected at the bottom of the guide rod 62, and a push plate 64 is connected between the tops of the two guide rods 62. The push plate 64 is located above the arc-shaped plate 41, and the bottom and inner sides of the sliding rods 43 on the front and rear sides are connected with connecting rods 65. The bottom of the connecting rods 65 is connected with a wedge-shaped block 66. The wedge-shaped block 66 cooperates with the contact wheel 63, and the guide rod 62 and the guide rod A second spring 67 is connected between the sleeves 61 .

...

Embodiment 3

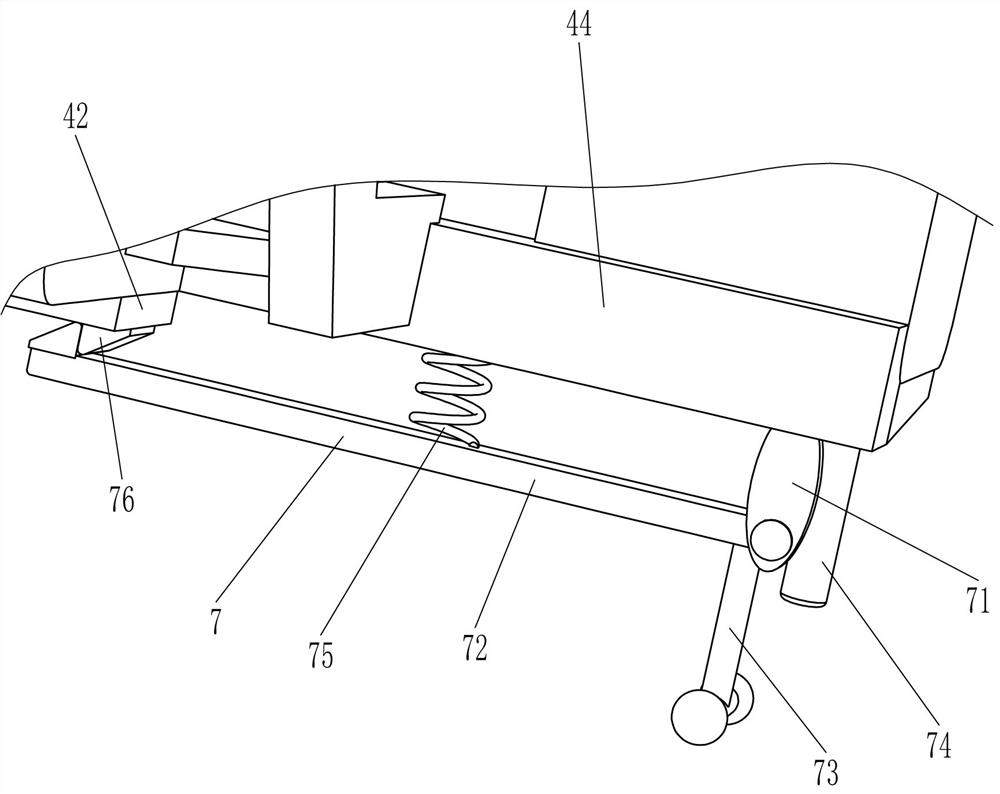

[0038] On the basis of Example 2, as Figure 8 As shown, a locking mechanism 7 is also included. The locking mechanism 7 includes a hinge plate 71, a hook 72, a pull rod 73, a limit rod 74, a third spring 75 and a blocking block 76. The bottom of the front side mounting plate 44 is connected with a hinge plate 71. The hinge plate 71 is hingedly connected with a hook 72, the front side of the hook 72 is connected with a pull rod 73, the front side of the front side mounting plate 44 is connected with a limit rod 74, the limit rod 74 cooperates with the pull rod 73, the hook 72 and the mounting plate 44 are connected A third spring 75 is connected between, and a locking block 76 is connected to the bottom of the front side sliding sleeve 42 , and the locking block 76 is matched with the hook 72 .

[0039] When the straw mat is rolled up, the hook 72 cooperates with the clamping block 76 to lock the mounting plate 44 to avoid displacement of the mounting plate 44. After the rolli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com